Dough mixer production technical requirements

For the pasta craftsmen, the quality of the noodles is the top priority. Only when the noodles and noodles are good, can the next operation be carried out. The technical requirements of the vacuum mixer: smooth noodles, smooth and strong, no bubbles, whitish and tough , Water-locking capacity is saturated and other advantages, Spring and Autumn will introduce some technical requirements in detail.

The vacuum kneading machine is different from other tumblers and meat grinders. The vacuum kneading machine requires very high intelligence and requires a lot of noodle quality, so it is very laborious in production and processing. What are the advantages of a good vacuum mixer?

For the pasta craftsmen, the quality of the noodles is the top priority. Only when the noodles and noodles are good, can the next operation be carried out. The technical requirements of the vacuum mixer: smooth noodles, smooth and strong, no bubbles, whitish and tough , Water-locking capacity is saturated and other advantages, Spring and Autumn will introduce some technical requirements in detail.

Professional dough mixer production technical requirements

1.Smooth surface

For many users, smooth surface quality is an essential processing point for dough. If you want to ensure smooth surface quality, vacuum mixers must have no dead corners and surfaces. Ensure the distance between the blade and the noodle box, and ensure the strength of the two ends and the noodles. Many manufacturers in this part cannot meet the requirements, causing the dough to be individually kneaded, the noodles are not strong enough, and the noodle quality is poor throughout the day. How to solve the problem, This part must work hard on the processing intensity.

2.No bubbles and toughness

How does the vacuum kneading machine make the dough bubble-free and strong? No bubbles for users, as long as the vacuum is in place, there are basically few bubbles. But strength and strength refer to the toughness and tension of the face. How to ensure it? This version requires special attention to the selection of processing items such as noodles, sliced noodles, ramen, steamed buns, and fire, so you must pay special attention to the tooth profile of the equipment, no matter what kind of production concept you are talking about. The selection of the tooth profile determines the yield of the surface quality and the processing parameters of the surface quality.

3.Facial texture is whitish, saturated and powerful

Vacuum noodle mixer For the single product of meat filling and vegetarian filling, the saturation of the noodle quality determines the damage rate of the finished product and the cost price. Why do you say this? A good vacuum mixer not only absorbs water, but also costs quality. Okay, the texture is whitish. At the same time, the selection is very important for the processing manufacturer. The vacuum and noodle machine is saturated with water to ensure that it does not absorb the salty taste inside, ensuring freshness and freshness. More tender. Moreover, the quick-freezing of the finished product does not break and the damage rate is low. For individual manufacturers, this is not done by adding food additives, but the vacuum and dough machine accounts for a large probability.

This machine is mainly suitable for mixing all kinds of high-grade pasta and pasta products. Quick-frozen foods include: all kinds of pasta, dough, steamed bun, dumpling, wonton wrappers, strips, dry and wet noodles, noodles, bread, fried small twists, pastries, pork nests, wontons, and fried buns, roasts Buns and so on. At the same time, it is an ideal equipment for the production of modern high-end noodles such as fresh-keeping noodles, udon noodles, quick-frozen dumplings, quick-frozen wontons, instant noodles, boiled noodles, steamed noodles, dried noodles, etc. It is not only suitable for the flour products industry, but also for similar operations in the chemical and pharmaceutical industries. According to the characteristics of wheat flour used in pasta products, different leaf forms can be selected to achieve different kneading effects.

Related Content

What kind of food can the samosa pastry sheet machine do?

Cookie Dropping Machine | Biscuit Making Machinery

Pita Bread Maker Kuwait | 500pcs/h pita bread line was shipped

Fully Automatic Pita Bread Production Line | Commercial Arabic Bread Making Machine

Flour Tortilla Making Machine | Vegetable Chapati Roll & Pita Bread Machine

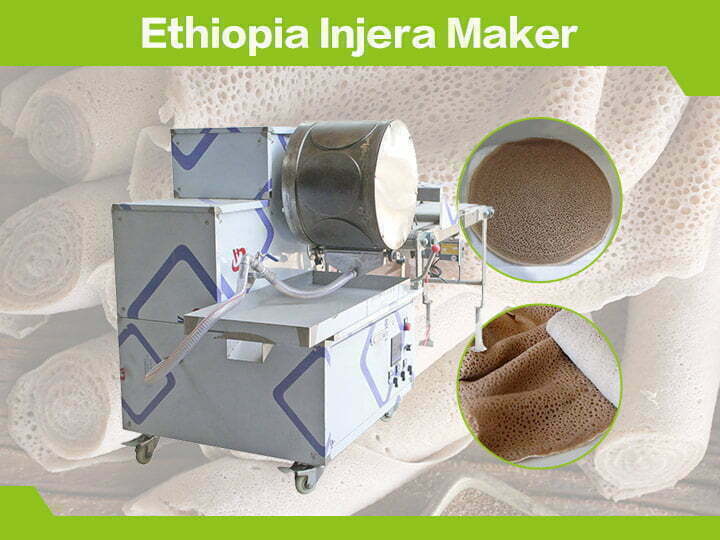

Ethiopian Injera Making Machine | Injera Maker Machine with Good Price

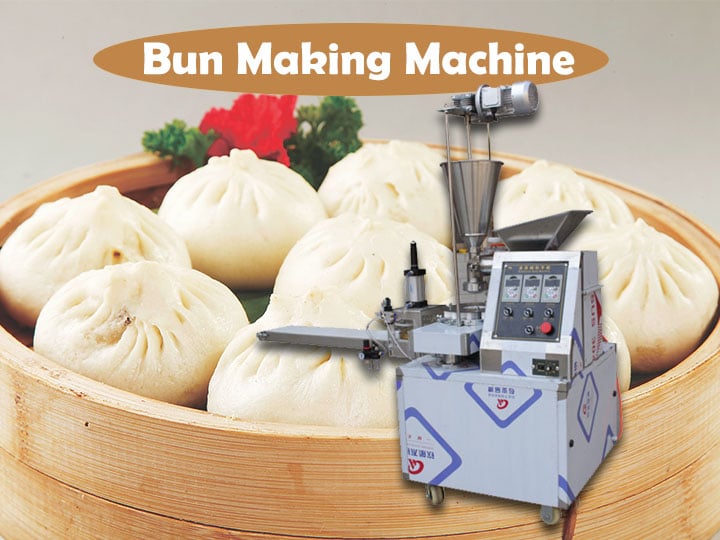

Does a large cafeteria need a fully automatic bun machine?

Bun Machine | Commercial Stuffed Buns Making Machine

Good maintenance methods of the tofu making machine