Peanut Candy Production Line | Peanut Brittle Chikki Making Machine

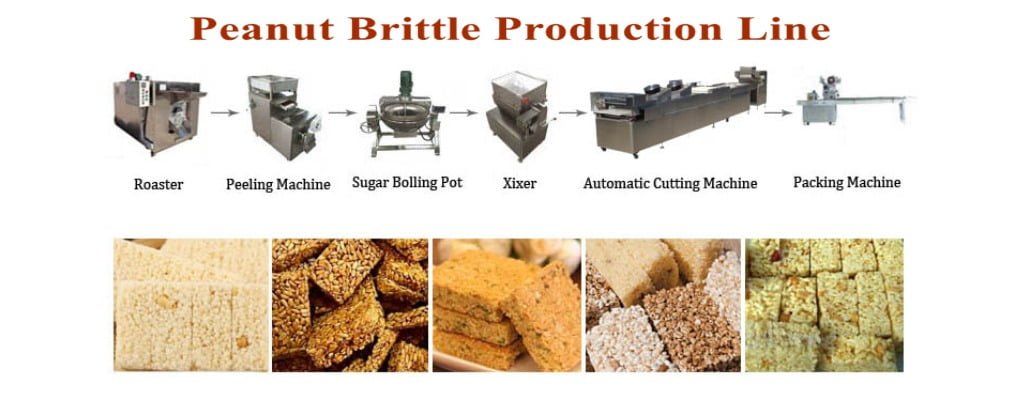

The peanut candy production line is an industrial processing line for making all kinds of peanut candy brittles, sesame brittle bars, nuts brittles, peanut chikki, cereal bars, and other casual snacks. The full set of peanut brittle making machines mainly include the peanut roasting machine, peanut peeling machine, caramel(sugar) boiling pot, automatic mixer machine, peanut candy forming and cutting machine, and peanut candy packaging machine. The commercial peanut brittle processing plant can replace manual labor to produce various crispy nut brittle snacks. At present, the peanut brittle processing line is very popular with customers in the United States, the Philippines, Saudi Arabia, Canada, Egypt, and other countries, and its output is in It can be customized between 100kg/h and 1000kg/h.

Raw materials for making peanut candy brittle

The main raw materials for making peanut candy are all kinds of nuts, spices, sugar (caramel, brown sugar), etc. Among them, nuts need to be roasted in a roaster before they are used to process peanut sugar, and raw nuts cannot be processed directly into peanut sugar. Nuts commonly used to make peanut candy are sesame, peanuts, almonds, walnuts, hazelnuts, sunflower seeds, etc. What we need to pay attention to is that different nuts have different temperatures during baking.

Peanut candy production line’s production process

In fact, the methods of industrialized processing of peanut candy and hand-made peanut candy are basically the same, but we use peanut brittle making machines instead of manual labor, which can improve production efficiency. The production process of the peanut candy production line includes raw materials roasting, roasted peanut peeling, sugar boiling, roasted peanuts and boiled sugar mixing, peanut candy forming and cutting, peanut candy bars packaging.

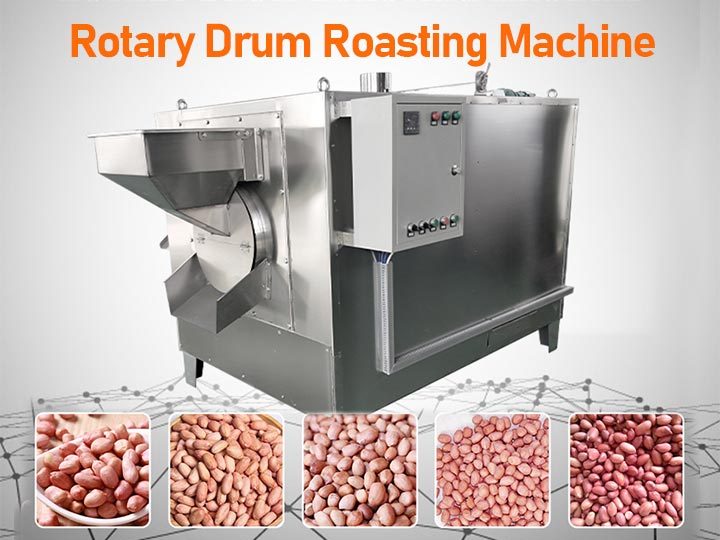

◊ Peanut roaster machine

The processing of peanut candy first needs to bake the raw materials to ensure that the raw materials are cooked. We can use this rotary drum type peanut roaster to roast peanuts, sesame seeds, almonds, etc. The heat source of the machine can be electric heating and gas heating. The rotary peanut roasting machine has higher roasting efficiency than other types of roasting machines because when the machine is working, its inner drum will continuously rotate to ensure that the raw materials are evenly heated.

◊ Roasted peanut peeling machine

Peanuts need to be peeled using an automatic peeling machine after roasting. This electric peanut peeling machine is mainly used to remove the red skin of the roasted peanut kernels. Peanuts need to be peeled to ensure the sweet taste of peanut candy. Peanut candy made from unpeeled peanuts is not only dull in color but also has a bitter taste. This small peanut peeling machine has high processing efficiency and will not cause peanuts to break.

◊ Sugar boiling machine

We usually use this jacketed cooking kettle to heat and melt solid granular caramel or white sugar to form sugar water. When making sugar water, we can also add an appropriate amount of honey and spices to mix. If the customer’s budget is not high, they can also purchase this sugar cooking equipment differently. It is also possible to use a big wok to boil the sugar water. However, the jacketed cooking pot has more processing capacity and higher safety.

◊ Sugar and peanuts mixer machine

After the sugar water is cooked, we need to mix and stir peanuts or other roasted nuts in a certain proportion. There is a layer of food-grade PE material in the mixing barrel of the automatic mixer, which can prevent the material from sticking to the wall of the mixing barrel. In addition, there is a mixing scraper inside the mixing barrel, which can continuously mix the materials to avoid condensation and make the mixing of the materials more uniform.

◊ Peanut brittle forming and cutting machine

We can use the peanut candy cutter to compact, cool, and cut the evenly mixed peanut candy. Usually, the peanut candy mass just after mixing is very big and the temperature is very high. We can connect the discharge port of the mixer to the feed port of the peanut candy cutting machine. In this way, the stirred peanut candy can be directly dropped into the peanut candy forming machine for processing, without the need for workers to transfer.

The peanut brittle is automatically pressed into a flat sheet during forwarding transportation on the automatic forming machine. In addition, the fan on the peanut brittle cutting machine will continue to blow air to gradually cool the peanut brittle. When the peanut candy enters the cutting system of the forming machine, it will be quickly cut into strips and blocks of uniform size.

◊ Peanut candy packaging machine

After the peanut candy is processed, we can use an automatic packaging machine to pack it into various specifications. This kind of peanut candy packaging machine is often used for packaging various foods. It can pack peanut candy according to different weights, sizes, and styles. Of course, packaging requirements can be customized according to user needs.