Chocolate Production Line | Automatic Chocolate Making Equipment

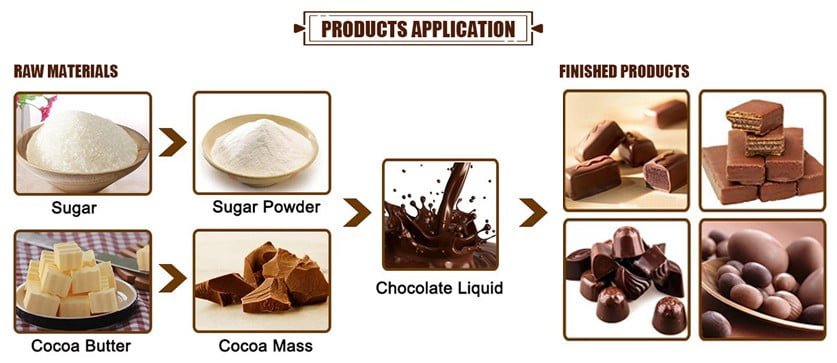

Chocolate is one of the most popular foods in the world. Its raw materials are mainly cocoa butter and cocoa powder. After the cocoa beans are fermented, roasted, and peeled, they are ground and pressed into cocoa liquor. Cocoa liquor can be separated into cocoa butter and cocoa powder, and then further processed into other types of chocolate food. With the increasing demand for chocolate in the market, the establishment of a complete chocolate production line is an indispensable step for chocolate manufacturers.

The production process of chocolate

Chocolate production mainly includes the steps of mixing, grinding, refining, tempering, casting, and forming.

- Raw material mixing: The process of uniformly mixing sugar, milk powder, cocoa mass, cocoa butter, and other auxiliary materials.

- Grinding: It is the process of grinding the uniformly mixed raw and auxiliary materials. This process can be divided into two steps according to the particle size of the obtained raw and auxiliary materials: coarse grinding and fine grinding.

- Refining: The main purpose is to remove the volatile acid, moisture, and peculiar smell of the slurry, and at the same time produce a burnt smell, highlighting the chocolate flavor.

- Tempering: The purpose of temperature adjustment is to make the cocoa butter crystals in the slurry form stable crystals and express them with a black luster. And it also aim to extend the shelf life of the product. (Temperature adjustment is the key process)

- Molding: Molding is to make the passing chocolate into various shapes. Liquid chocolate material is poured into a quantitative model plate during this process. When the material temperature drops below the melting point of cocoa butter, the stroked crystal forms are arranged according to strict crystallization laws, forming a dense texture state, resulting in obvious volume shrinks, and finally forms a variety of colorful and beautiful chocolate products.

Main components of the chocolate making machines

The chocolate production line is mainly composed of the cocoa melter, Chocolate conche, temperature holding tank, continuous tempering machine, and the final chocolate forming machine. Auxiliary equipment can also be equipped with the powder sugar machine, the decorating machine, chocolate coating pan, chocolate delivery pump, etc.

Cocoa melter

The cocoa melter is auxiliary equipment to produce chocolate, mainly used for melting cocoa liquor or cocoa butter substitute to meet the requirements of chocolate production.

| Model | Water temperature in the jacket(°C) | Capacity(kg) | Dimension(mm) | Heating power(kw) |

| SL-RYG-120 | 40-65 | 120 X 3 | 1900x650x1000 | 10 |

| SL-RYG-250 | 40-65 | 250 X 4 | 2082x1036x1000 | 12 |

| SL-RYG-1000 | 40-65 | 1000 | 2550x1670x1820 | 15 |

Chocolate conche

Chocolate conche is the main equipment in chocolate production. It is used to finely grind chocolate slurry. It has the dual functions of grinding and refining. It is the most ideal equipment for producing chocolate slurry. The refiner adopts automatic motor tightening and PLC automatic control and has multiple functions such as refining, grinding, deodorization, dehydration. It also has the advantages of convenient maintenance, leak-proof and durable, stable grinding, energy saving. This machinery is mainly used for fine grinding of chocolate paste, also suitable for jam, peanut butter, and other liquid fuel.

| Model | Capacity(L) | Fineness(μm) | Grinding Time(h) | Motor power(KW) | Weight(kg) | Dimension(mm) |

| SL-JMJ-40 | 40 | 20-25 | 7-9 | 2.2 | 330 | 1000X800X800 |

| SL-JMJ-500 | 500 | 20-25 | 14-20 | 15 | 2300 | 2430X1180X1400 |

| SL-JMJ-1000 | 1000 | 20-25 | 14-20 | 22 | 3420 | 3000X1400X1800 |

| SL-JMJ-3000 | 3000 | 20-25 | 18-24 | 55 | 7000 | 3700X1900X2200 |

Temperature holding tank

The temperature holding tank is a special storage container for the chocolate slurry after fine grinding or ball milling, which can keep the chocolate slurry at the rated temperature. Heat preservation and stirring can reduce the water content in the chocolate mass and increase the fluidity of the chocolate, making it smoother in the mouth and having a longer shelf life. All models of this series are electric heating and automatic temperature control.

| Model | Capacity(L) | Motor power(KW) | Weight(kg) | Dimension(mm) |

| SL-BWG-50 | 50 | 0.75 | 120 | Φ490X750 |

| SL-BWG-500 | 500 | 0.75 | 350 | Φ1000X1380 |

| SL-BWG-1000 | 1000 | 1.5 | 470 | Φ1220X1850 |

| SL-BWG-3000 | 3000 | 4 | 2500 | Φ1700X2500 |

| SL-BWG-7500 | 7500 | 11 | 5200 | Φ2600X3050 |

Chocolate continuous tempering machine

The chocolate continuous tempering machine is essential equipment for the production of natural cocoa butter and cocoa butter-like (CBE) chocolate. This series of machines is a special temperature adjustment method determined according to the change law of the chocolate slurry crystal form and the growth and formation of stable crystal forms at different temperatures. It can strictly and automatically control the different temperatures required by the chocolate slurry in each process stage. It can ensure the quality of chocolate products, make the natural flavor of chocolate stronger, smooth taste, bright color, and good preservation.

| Model | Capacity(L) | Motor power(KW) | Weight(kg) | Dimension(mm) |

| SL-TWJ-100 | 100 | 7.25 | 450 | 980X840X1855 |

| SL-TWJ-250 | 250 | 7.75 | 670 | 980X840X2060 |

| SL-TWJ-500 | 500 | 10 | 800 | 1100X970X2050 |

| SL-TWJ-1000 | 1000 | 26.75 | 1200 | 1760X1440X1960 |

| SL-TWJ-2000 | 2000 | 34.5 | 1500 | 1760X1440X1960 |

Chocolate forming machine:

The hocolate forming equipment includes the chocolate drop-casting machine, chocolate casting moulding machine, enrobe moudling machine, chocolate bean forming machine, etc.

Chocolate drop-casting machine

The chocolate drop-casting machine is specified equipment to produce small granule chocolate. The chocolate liquid dripping directly onto the PU conveyor belt and moves into the cooling tunnel for cooling, according to the roller under the conveyor belt, the chocolate granules fall automatically. The machine has characteristics of accurate control, simple operation, a wide range of usage, and large production capacity.

| Model | Conveyor Belt Width (mm) | Drop Frequency(per/min) | Tunnel work temperature(°C) | Power(kw) | Weight(kg) | Dimension(mm) |

| SL-DJJ-600 | 600 | 12-15 | 0-10 | 9.02 | 1500 | 14000X950X1750 |

| SL-DJJ-800 | 800 | 12-15 | 0-10 | 10.52 | 2000 | 16000X1150X1750 |

| SL-DJJ-1200 | 1200 | 12-15 | 0-10 | 22.2 | 2500 | 16000X1550X1750 |

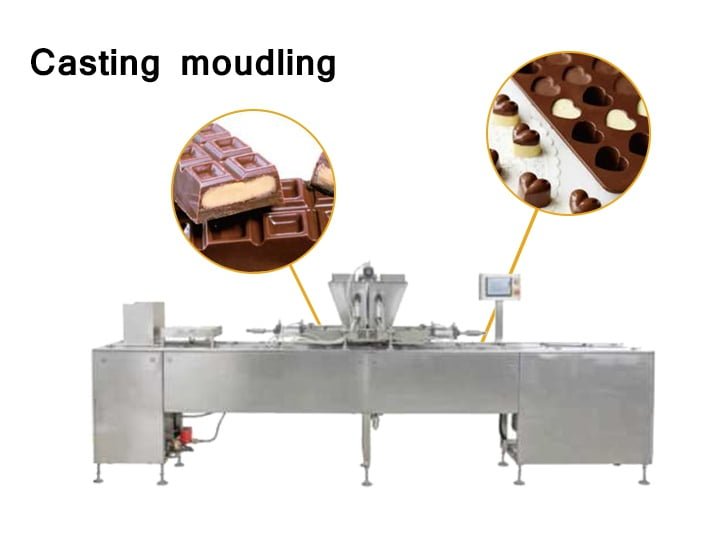

Chocolate casting moulding machine

This chocolate casting moulding machine adopted pouring three times and filling twice (crispy nuts and full nuts). It collects baking, moulding, rolling over, vibrating, and cooling together. With this machine, you can produce pure chocolate, a variety of chocolate with different sizes, fillings, multi-colors and multi-tastes. It has advantages of high productivity, varieties, tidiness, utility, etc.

| Model | Capacity(T/Day) | Power(kw) | Moulding Board Dimension(mm) | Weight(kg) | Dimension(mm) |

| SL-JZJ-150 | 1.5 | 7.47 | 275X175 | 5000 | 4000X520X1500 |

| SL-JZJ-275 | 1.5-2 | 20 | 280X200 | 6000 | 16000X1100X2100 |

| SL-JZJ-510 | 2-2.5 | 20.64 | 470X200 | 7500 | 20510X1065X1940 |

Enrobe moudling machine

The enrobe moudling machine is specified equipment used for enrobing chocolate on the surface of products such as candies, cakes, and biscuits, etc. Using this machine, you can make various unique flavors.

| Model | Mesh belt width(mm) | Cooling temperature(°C) | Power(kw) | Weight(kg) | Dimension(mm) |

| Sl-TYJ-400 | 400 | 0-10 | 12.35 | 2000 | LX1192X1580 |

| Sl-TYJ-800 | 800 | 0-10 | 25.44 | 2800 | LX1280X1835 |

| Sl-TYJ-1000 | 1000 | 0-10 | 29.84 | 3600 | LX1650X1800 |

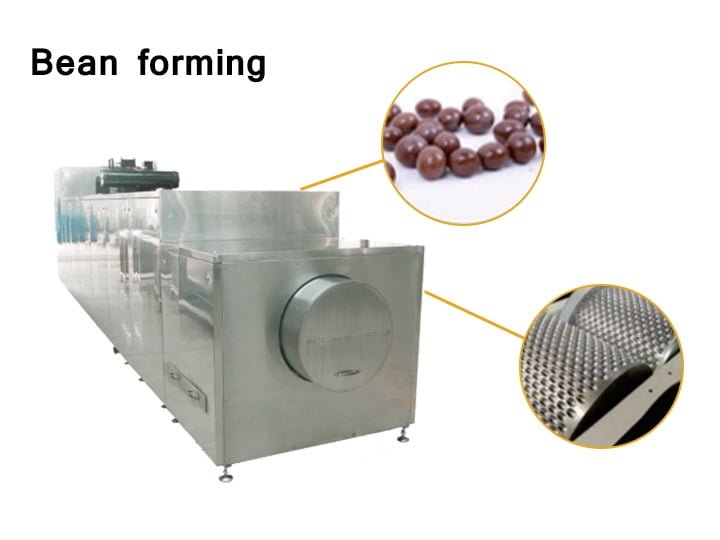

Chocolate bean forming machine

The chocolate bean forming machine is specially used for cold rolling to produce chocolate. The equipment is designed for entirely closed production, avoid operator contacting chocolate, and keep the chocolate products to reach food sanitation standards. The equipment shows energy saving .mass production capacity, high safety and automation, ease of operation. The equipment can produce kinds shapes of pure chocolate, including ball-shape, ellipse shape, bean shape, etc.

| Model | Roller Width(mm) | Capacity(kg/h) | Cooling Time(min) | Power(kw) | Dimension(mm) |

| SL-DCX-400 | 400 | 100-150 | 18-30 | 25 | 8620X1040X2100 |

| SL-DCX-600 | 600 | 150-250 | 18-30 | 30 | 8620X1480X2100 |

Auxiliary equipment

- Sugar Powder Machine is mainly used to pulverize granulated sugar into powdered sugar powder to improve the subsequent refinement efficiency.

- The Decorating Machine is designed for the special purpose of decorating biscuit and chocolate surfaces with chocolate patterns. Mesh belt width selective from 400, 600, 800,1000 and 1200mm.

Sugar mill

Ball mill

Chocolate coating pan

Chocolate Coin packing machine

Chocolate packing machine

Spreader

- Chocolate Coating Pan is suitable for the polishing and coating of different shape of chocolate products such as circular, flat, oval and cylindrical form etc. Chocolate polished and coated are excellent in lustre, colour and shape. Cylindrical chocolate packed in colour aluminium foil polished in the machine will have a tight, plain and clear-cut appearance. The surface of various candied fruits and nuts can also be coated with chocolate evenly by this polishing machine.

- Chocolate Delivery Pump is specialized for delivery of chocolate mass. The pump body is equipped with double-jacketed to keep warm. Customers can choose different model according to the flow rate required. The pump can be used individually or with other production lines for automatic chocolate mass feeding.

Features of the chocolate production line

- Each machine in this chocolate processing line is made of the high-quality stainless steel, so that can make sure the cleanliness and sanitation of the whole process for chocolate.

- The refiner and ball mill can be connected by a pump and used together, which can greatly shorten the refining time and improve work efficiency.

- No matter what capacities you want, we can customize the most suitable plan for you based on your requirements, your investing budget and so on. And we can also help you do the cost and profit analysis according to your local consumption customs.

- All these chocolate processing machines are made of the high-quality stainless steel so that the whole chocolate making process is non-pollution, clean and hygienic, which can ensure good chocolate quality.

- Each of the chocolate making machines in this production line is resistant to corrosion and wear, easy to operate and maintain, and they are cost-saving and have a high return on investment.

- The automatic chocolate production line has a high degree of automation, which can replace workers to clean materials, reduce labor intensity and save labor costs.