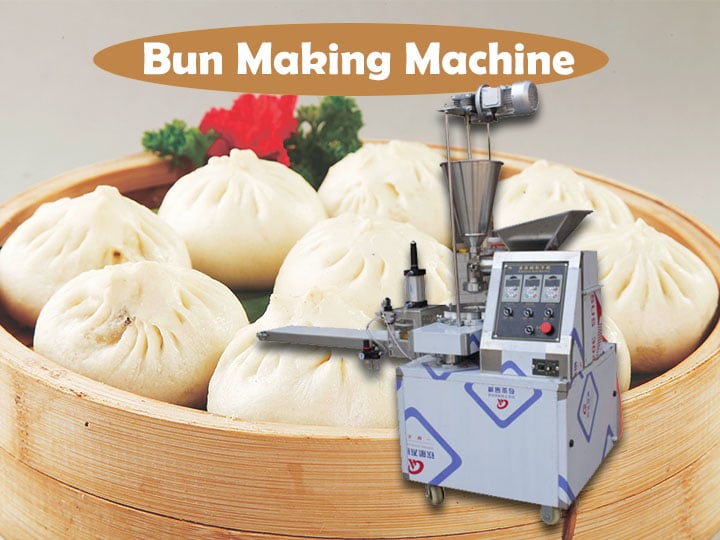

Bun Machine | Commercial Stuffed Buns Making Machine

The bun machine, as well as the steam stuffed bun making machine, which is a commercial type of flour food processing equipment. This stuffed buns machine mainly can make all kinds of buns with various stuffings, like bean paste buns, meat buns or vegetable buns, and so on. By the way, we also have a dough mixer to help you knead the dough. Commercial Chinese buns forming machine is very efficient and it is widely used in many pastry shops, bakeries, and restaurants.

What are the stuffed buns?

The stuffed bun also can be called baozi, which is a little different in different countries. For example, the traditional Chinese buns are always the steamed type which is made of the dough sheets and various fillings. However, the foreign stuffed buns are always the filled bread that is baked with the stuffed bread. Nowadays, with the popularity of Chinese food and recipes, the steam stuffed buns are popular in many foreign countries. Besides, buns can be made with different shapes and flavors so that they are very attracting and delicious.

How to make stuffed buns with a commercial bun machine?

The traditional way of making steamed buns is all by hands. The labor makes the dough by mixing the flour with water at a proper ratio and then roll out the bun wrappers with a certain size. Next, add the fillings into the bun wrappers and wrap the buns. The last step is to lay these buns on the steam pot for near 20 minutes steaming. The traditional way of making buns is very inefficient and costly.

The automatic bun machine can totally imitate the way to make steamed buns by labors. Commercial bun making machine has an electric controlling system which can control the filling adding and buns forming automatically. And the final stuffed buns can be steamed or baked directly for sale.

The main structure of the automatic bun making machine

The bun machine consists of five main components, including dough feeding system, fillings feeding system, bun forming system, finished product conveying system and automatic control system. The main body and outer casing of the machine are made of stainless steel and are durable for use.

Based on different customer requirements for the working capacities, this machine mainly has two types: the double-hopper bun maker machine and the single-hopper buns machine. The main difference between these two types of bun making machine is that the former one has two dough feeding hopper and its fillings feeder is bigger so that the double-hopper bun making machine has a larger output.

Technical parameter:

| Model | TZ-1-12 |

| Voltage | 220v/110v (50hz/60hz) |

| Power | 2.2kw |

| Output | 3600 pcs/h |

| Dimension | 1400×700×1500mm |

| Weight | 240kg |

Technical parameter:

| Model | TZ-2-12 |

| Voltage | 220v/110v (50hz/60hz) |

| Power | 2.2kw |

| Output | 3600 pcs/h (or more) |

| Dimension | 1400×700×1700mm |

| Weight | 240kg |

Working process of the buns machine

The dough feeding system of the bun forming machine is a special double helix structure, which can continuously squeeze the dough into the inner surface groove and the out mouth, and finally extrude the dough into a hollow surface tube shape. Place the fillings in the feeding system, and the inner spiral can stir the filling evenly, and the spiral then injects the fillings into the hollow noodle tube through the conveying pipe and the filling nozzle of the buns processing machine.

The cylindrical tube after filling will automatically enter the bun forming system. The molding system is a disc-shaped structure, and the buns can be made by the continuous stretching of the extrusion die. The formed bun will automatically drop onto the conveyor and output. Workers can take the buns out of the conveyor and send them to the steamer for steaming.

How to clean and maintain the automatic bun machine?

- After the machine is finished, remove the parts and clean them in time. In particular, the molding die should be coated with cooking oil after disassembly and cleaning to extend the service life of the mold.

- For long-running parts, apply grease regularly to lubricate. In addition, the tank in the molding system of the steamed buns processing machine should be greased for a long time for lubrication.

- The consumable parts of the buns making machine should be repaired and replaced in time to avoid affecting the normal use of the machine. The motor of the machine cannot be operated in reverse, otherwise, the machine parts will be damaged.

Great features of the bun making machine

- This machine is designed with advanced design so that it is compact and reasonable in Besides, it is easy to operate, easy to disassemble and clean.

- The buns maker is made of high-quality stainless steel, which is corrosion and wear-resistant, has a long service life and low failure rate.

- In addition, the size of the finished buns can be set and adjusted according to customer needs, and we can also provide a variety of buns filling formulations for free.