Commercial sweet potato peeling machine exported to Uganda

Sweet potato deep processing equipment mainly includes the sweet potato washing machine, sweet potato peeling machine, sweet potato slicer, etc. For most food processing plants and vegetable wholesalers, sweet potato cleaning and peeling machines are ideal equipment. Especially, the sweet potato peeler is often used in the processing plant for producing sweet potato fries. Our…

Sweet potato deep processing equipment mainly includes the sweet potato washing machine, sweet potato peeling machine, sweet potato slicer, etc. For most food processing plants and vegetable wholesalers, sweet potato cleaning and peeling machines are ideal equipment. Especially, the sweet potato peeler is often used in the processing plant for producing sweet potato fries. Our factory recently exported a commercial sweet potato peeling machine to Uganda, with a processing capacity of 500kg/h. In fact, our factory has exported sweet potato cleaning and peeling equipment to Uganda many times.

Overview of sweet potato planting in Uganda

In terms of the harvested area and output of sweet potatoes, Uganda is the largest sweet potato producer in Africa. The country is the eighth largest producer of sweet potatoes in the world, producing approximately 1,656,981 tons of sweet potatoes in a harvested area of 391,974 hectares. The production of sweet potatoes in Uganda is mainly concentrated in densely populated areas (1000-2000 m).

The growth of sweet potatoes requires a temperature between 15 °C and 35 °C, relatively high light intensity, and an average annual rainfall of 750-1000 mm. Uganda is located in the equatorial region, with abundant rainfall and long hours of sunlight for most of the year, so plants can benefit from its hot and humid climate.

Sweet potato is the third most important crop in Uganda, second only to bananas and cassava grown at least twice a year in all regions of Uganda. The cultivation of sweet potatoes in Uganda accounts for about 55% of its tuber crop arable land.

Main applications of sweet potato peeling machine in Uganda

The sweet potato peeler machine and sweet potato washing machine sold by our factory in Uganda are often used in local food processing plants. Many customers in Uganda are engaged in the deep processing of sweet potato by-products, such as processed and baked sweet potato chips, crispy sweet potato fries, sweet potato flour, etc.

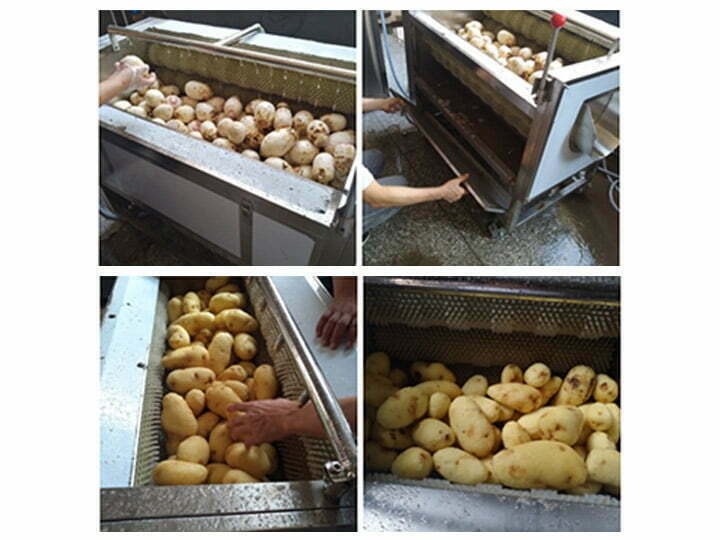

The commercial sweet potato peeling machine uses the slow rotation of the hard brush in the washing machine and the friction between the sweet potato and the sweet potato to quickly clean and peel the sweet potato. The upper part of the cleaning and peeling machine is equipped with a water outlet pipe for continuous water discharge.

Hard bristles with uneven heights are uniformly distributed on the bottom surface and the middle and lower sides of the machine, which can realize the continuous rolling of the sweet potato in the machine. The cleaning time for each batch of sweet potatoes is about 5-10 minutes (the specific cleaning time depends on the freshness of the sweet potatoes).

Advantages of Taizy sweet potato peeling machine

- The machine is made of 304 stainless steel plate, durable, clean, and hygienic.

- The bottom of the sweet potato peeling machine is supported by four casters with brakes, which can be easily moved and fixed.

- The hair rollers of this sweet potato cleaning machine are grouped and connected by high-quality chains, which are more wear-resistant, more bearable, and safer, and more reliable than traditional overall chain connections.

- The high-quality motor and pulley drive system of the machine makes the equipment start more stable, with lower noise and longer service life.

- The commercial sweet potato peeler is easy to operate. Workers only need to feed materials and press the start button to put the equipment into operation. This design greatly reduces the labor intensity of workers and can save labor costs.

Related Content

How to Make French Fries in Factory?

Onion peeling machine for skin removing

Complete Potato Washing Line Plant | Peeling Slicing Drying Packaging

How is the potato washing and peeling machine price?

200kg/h frozen french fries production line was installed in Egypt

Global frozen fries demand soars in 2020! Why?

How to make frozen french fries at home as delicious as McDonald’s?

Comprehensive potato chips production solutions in 2020

French Fries Processing Machine | French Fries Making Machine