Commercial Jacketed Kettle for Cooking

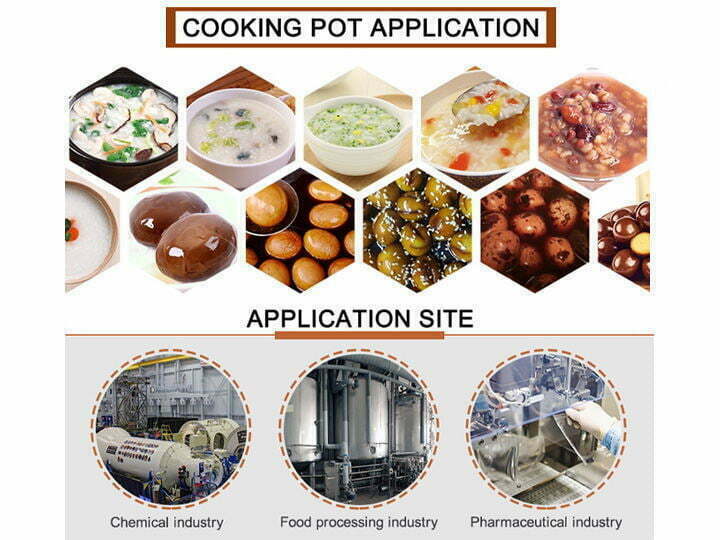

The jacketed cooking kettle is also known as a jacketed cooking pot, jacketed kettle cooker, and so on. This cooking pot is widely used in food processing such as candy, pharmaceuticals, dairy, alcohol, pastry, beverage, honey line, canned food, etc. This jacketed cooking kettle can also be used for food processing in large restaurants or canteen soups, cooking dishes, stews, and porridge, besides, it can also be used to fry sunflower seeds and fried tea leaves.

The jacketed kettle uses steam with a certain pressure as the heat source (optionally electric heating, gas heating, etc.). It has the characteristics of a large heating area, high thermal efficiency, uniform heating, short boiling time of liquid material, and easy control of heating temperature.

Jacketed cooking pot’s working video

What is a jacketed kettle for cooking?

With the improvement of technology and the improvement of people’s living standards, we have stricter requirements on food safety quality, so the sandwich pots are made of stainless steel. There are more and more people using the jacketed pan, and they have slowly replaced traditional iron-burning pots. The heating method of the jacketed cooking pot is generally adopted by steam heating, electric heating, and liquefied gas natural gas heating, which is energy-saving environmentally friendly, and convenient to use.

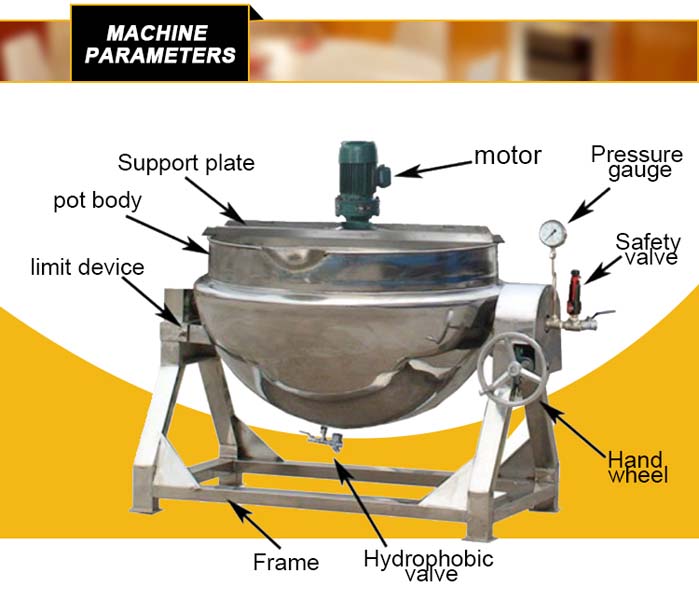

The main structure of the jacketed pot

The food jacketed kettle cooker usually consists of a pot and a foot. The pot body is a two-layer structure consisting of a spherical body inside and outside, and the middle layer is heated by steam(or electric). This cooking pan is mainly composed of the pot body, support plate, motor, pressure gauge, frame, hand wheel, and so on. According to different working requirements, this cooking pot can be of different types and models, and each type has its own special features for food processing or industrial usage.

Classification of the jacketed kettle cooker

Jacketed pots can be divided into many different types according to different classifications.

- Structure form: this jacketed pan is available in fixed type, tiltable type, and agitated type.

- Heating method: the jacketed cooking pot is divided into electric heating type, steam heating type, and gas heating type.

- Production needs of the process: it can be divided into with or without mixing equipment.

- Sealing method: the sandwich pot can be divided into no cover type, flat cover type, and vacuum type.

The difference between the three heating methods: the electric heating sandwich pot is heated by the electric heating tube to heat the heat transfer oil; the steam sandwich pot is heated by the steam generated by the boiler to the jacket of the sandwich pot. Gas heating uses natural gas, liquefied gas, or pipeline gas as a heat source to solve the problem of using a sandwich pot without steam. A temperature control system or agitator can be configured if needed.

1. Working principle of the Gas-heating jacketed cooker

When using a gas heating sandwich pot, first open the jacketed kettle gas valve, ignite the gas, and manually add the cooking oil to the pot. When the oil temperature reaches the cooking temperature, add an appropriate amount of material, manually turn the pot, and stir to make the material evenly heated in the pot (the same principle as the domestic cooking pot). After the material is processed, turn off the gas and turn off the flame. Turn the handle and turn the worm gear and the worm to tilt the volute and pour the material into another container. Then this food processing is finished.

2. Electric jacketed pan working principle

The electric heating jacketed pot uses electric heating as a heat source and heat transfer oil as a medium. During work, the material is transported from the feed port to the pot, and the electric heating rod at the bottom of the jacket of the pot heats the heat transfer oil in the jacket so that the material in the pot is rapidly heated for a short time.

The electric heating sandwich pot is heated to a predetermined temperature to save time more than steam heating. The electric heating cooking pot does not need to withstand pressure during operation, so the heating time is short. The electric heating cooking pan has the characteristics of a large heating area, high thermal efficiency, uniform heating, short heating time, and easy temperature control.

3. Steam jacketed kettle working principle

The pot body of the steam sandwich pot is a double-layer structure composed of a spherical body inside and outside, and the middle jacket is heated after being heated by steam. The steam cooking kettle uses steam of a certain pressure as a heat source. When working, the inlet ball valve is opened to start ventilation heating, and when the material heating is completed, the inlet ball valve is closed. The steam jacketed pan has a large heating area, high thermal efficiency, and uniform heating. The boiling time of the liquid material is short, and the heating temperature is easy to control.

Applications of the electric jacketed kettle with mixer

The sandwich pot is widely used in food processing and brewing, such as candy, cakes, beverages, juice, jam, candied fruit, dairy and canned food, winemaking, pharmaceutical, and daily chemical industries. It can also be used as important equipment for melting, disinfecting, heating, blanching, pre-cooking, formulating, cooking, and concentrating materials. In addition, due to high work efficiency, the jacketed pan can be used for large hotels, restaurants, hotels, guest houses, restaurants, and canteens as porridge, soup, boiled dumplings, cooking, and stew.

Jacketed cooking kettle’s main features

- The jacketed pan heating speed is fast and the heating is relatively uniform. The material has a large heating area and high thermal efficiency.

- The material for making the sandwich pot is mainly stainless steel. Customers can choose different materials according to their specific production needs. We can also customize the machine according to the customer’s needs, including structural style and output.

- This jacketed cooking pot has a simple and compact structure with the advantages of convenient operation, and safe and reliable use so that it can be widely used in many fields.

Technical parameters of the commercial jacketed cooker machine

| Model | Weight(kg) | Diameter(mm) | Output(L) | Dimension(mm) |

| TZ-JCG-100 | 90 | 700 | 100 | 1300*1000*1220 |

| TZ-JCG-200 | 110 | 800 | 200 | 1400*1100*1300 |

| TZ-JCG-300 | 130 | 900 | 300 | 1500*1200*1500 |

| TZ-JCG-400 | 140 | 1000 | 400 | 1600*1300*1550 |

| TZ-JCG-500 | 150 | 1100 | 500 | 1700*1400*1600 |

| TZ-JCG-600 | 160 | 1200 | 600 | 1800*1500*1650 |

The above are the parameters of six commercial jacketed kettles. Each machine has a corresponding weight, diameter, and output. The output of a small jacketed pot is 80kg and the large one is 600kg. You can choose according to your needs. If you have any questions, please feel free to contact us.