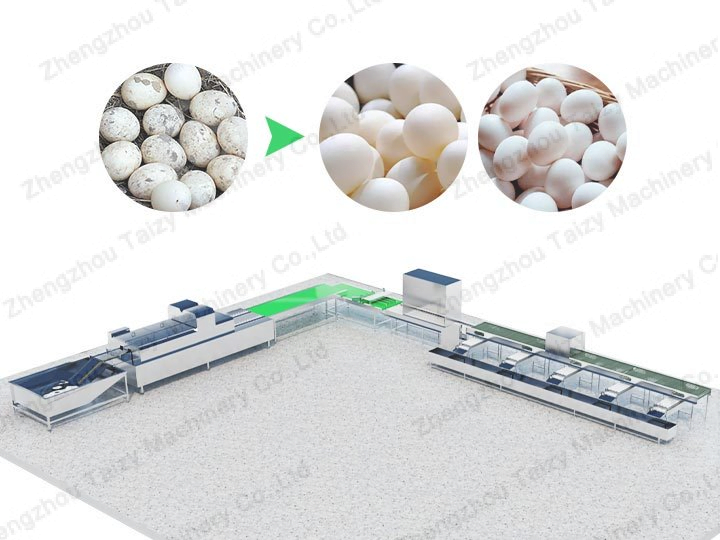

Egg cleaning machine for washing eggs

The egg cleaning machine is a device used to clean eggs. It can also be used to clean duck eggs and goose eggs. Eggs that have just been produced by chickens and ducks will be dirty. For farms, machines need to be used for egg cleaning. Egg washing includes automatic egg tank feeding, egg washing, air drying, and light inspection.

Working principle of Egg cleaning machine

- Egg Loading: Eggs are loaded onto the machine, usually through a conveyor belt or a tray system. The eggs are carefully placed to ensure they don’t crack or break during the cleaning process.

- Pre-Cleaning: In some machines, the eggs may undergo a pre-cleaning stage, where larger debris such as feathers, straw, or loose dirt is removed manually or through a mechanical process like air blowers.

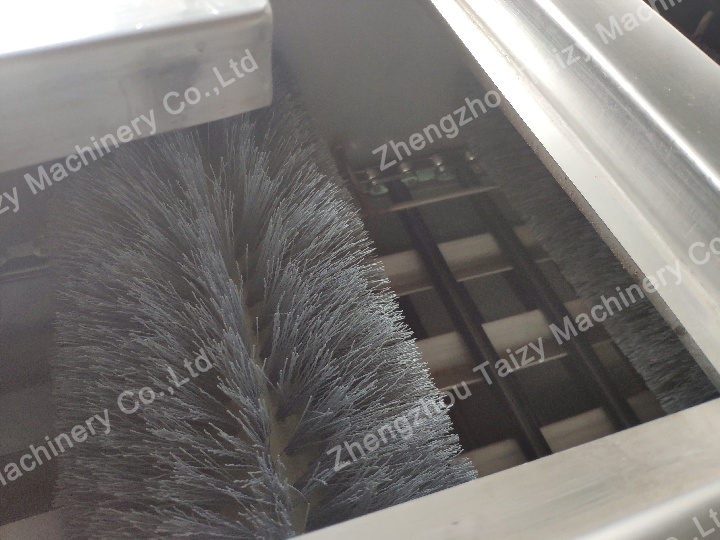

- Brushing and Scrubbing: The eggs move through brushes or soft scrubbing rollers that rotate gently and come into contact with the eggshells. These brushes effectively remove dirt, stains, and finer contaminants adhering to the egg surface.

- Washing: Water jets or sprayers are used to wash the eggshells thoroughly. The water helps to remove remaining dirt, debris, and any cleaning agents that may have been applied.

- Drying: After the washing process, the eggs may go through a drying stage to remove excess moisture. Drying can be achieved through the use of warm air blowers or other drying mechanisms. It’s crucial to ensure the eggs are completely dry before packaging or storage to prevent bacterial growth.

- Sanitization (Optional): Some advanced egg cleaning machines may incorporate sanitization systems, which apply a safe and approved sanitizing solution to further reduce bacteria or pathogens on the eggshells.

- Quality Inspection: Modern egg cleaning machines may also include an automated quality inspection system. This system checks the eggs for cracks, defects, or abnormalities, removing any damaged or compromised eggs from the process.

- Egg Collection: Once the cleaning and drying processes are completed, the eggs are collected and prepared for packaging or further processing.

The benefits of cleaning eggs

Egg cleaners are mainly used in poultry farms, food factories, and agricultural product processing technology fields. Poultry eggs are discharged from the reproductive holes of poultry, which are very easy to contaminate intestinal microorganisms; chicken manure and other harmful pollutants on the surface of eggshells contain pollutants that are harmful to humans, and fresh eggs have been cleaned and packaged. product. Clean egg surface is hygienic, and clean, and has a long shelf life, which greatly improves the quality and safety of fresh eggs.

An automatic egg feeding machine

Eggs are very easy to break when they are not cooked, so the most difficult thing for egg cleaning is how to automatically put the eggs on the egg cleaning machine. This egg cleaning machine uses the buoyancy of water to avoid collision between eggs and eggs, and can automatically put eggs on the machine. When working, put water in the water tank of the egg cleaner machine, and then it will be automatically placed on the egg washing equipment for the next step.

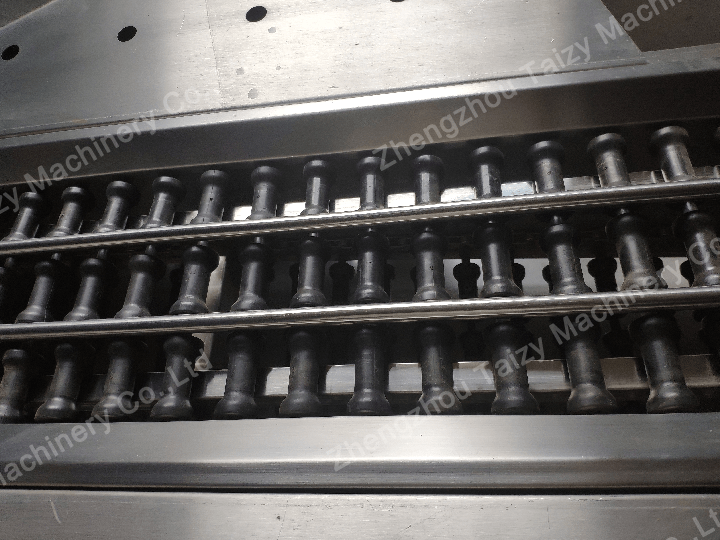

Roller conveying egg

Since the shape of the egg is oval, the ordinary conveyor belt cannot play a fixed role, and the use of the roller conveyor belt can not only carry out transportation but also play a fixed role. The roller conveyor also keeps the eggs tumbling as they wash, allowing the eggs to be thoroughly washed. Egg transport rollers are made of corrosion-resistant soft materials, which do not hurt eggs and increase friction, which is convenient for even egg-laying.

Brush cleaning eggs

It is made of specially curved wire with wear-resistant material, which has high wear resistance and excellent elasticity and can effectively remove the stains on the surface of eggshells. The shaft is made of stainless steel, which is not easy to corrode.

Air-dry and light inspection

After the eggs are cleaned, they are continuously transported out by the conveyor belt. There will be a fan above the egg cleaning line to speed up the drying. After drying, the light source will be tested. The LED cold light source is emitted from the bottom of the egg, and the cracked, scattered yellow, deformed, and other unqualified eggs are manually picked out to ensure the quality of the eggs.

Two different egg cleaning machine models

There are two models of egg washers, single row egg washers and double row egg cleaning machine. The difference between these two egg washers is the difference in output.

Single-row egg washing machine equipment parameters

| Appearance | 6000*1200*1500 mm |

| Efficiency | 5000-7000 pieces/hour |

| Voltage | 380V |

| Total power | 6.6kw |

The working efficiency of the single-row egg-washing machine is about 6,000 pieces/hour, and the total power is 6.6kw, including egg-laying, cleaning air-drying, and light inspection.

Double-row egg cleaner machine parameters

| Efficiency | 10000-14000 pieces/hour |

| Voltage | 380V |

| Total power | 12.5kw |

The working efficiency of the double-row egg washing machine is about 13,000 pieces/hour, and the working efficiency of the double-row egg cleaning machine is higher. About 2 times that of a single-row egg washer.

Can the egg cleaning machine wash different types of eggs?

The egg washing machine can clean different types of eggs, such as duck eggs, and goose eggs. Whether the machine can clean eggs of different sizes mainly depends on the size and type of the machine brush. Type, or change the brushes of different sizes, adjust the interval of the brushes, and you can wash eggs of different sizes.

Applicable scene of egg cleaning machine

Egg cleaning machines are commonly used in various applicable scenes where eggs are collected, processed, and prepared for consumption or distribution. Some of the main applicable scenes of egg cleaning machines include:

- Egg Farms: Egg cleaning machines are often used on egg farms where eggs are collected directly from chicken coops. They help remove dirt, feathers, and other contaminants from the eggshells, improving their appearance and quality before they are packaged and sent to market.

- Egg Grading and Sorting Facilities: In egg grading and sorting facilities, eggs are sorted based on their size and quality. Egg cleaning machines are used as part of this process to ensure that all eggs meet the required cleanliness standards before they are sorted and packed accordingly.

- Egg Processing Plants: Egg processing plants handle a large volume of eggs and require efficient cleaning methods. Egg cleaning machines are utilized to clean eggs on an industrial scale, facilitating the production of clean and safe eggs for various purposes, such as retail sales or egg-based products.

- Egg Distribution Centers: Before eggs are distributed to retailers or consumers, they may go through distribution centers. Egg cleaning machines ensure that eggs remain clean and hygienic during the distribution process, maintaining their quality until they reach the end users.

- Food Service and Hospitality Industry: Restaurants, hotels, and other food service establishments that use eggs as part of their menus may employ egg cleaning machines to maintain the cleanliness and safety of the eggs they serve to their customers.

Advantages of egg washers

The egg washing machine has a strong processing capacity and can be adjusted by frequency conversion. The number of eggs washed per hour is determined according to the specifications of the equipment. The surface of the processed eggs is free of dirt and shiny and can be spliced with other equipment. It can be connected to an egg grading machine and egg inkjet printer to complete egg processing with more functions. The processed eggs have higher added value and higher profits.