The features of the vegetable bubble cleaning machine

The fruit and vegetable bubble cleaning machine equipment is suitable for the cleaning of fruit and vegetable raw materials, especially for the cleaning of soft fruit and vegetable raw materials. The washing water is filtered and recycled, which consumes less cleaning water. The cleaning machine materials are slowly rinsed in the water through the mesh belt. The discharge end is equipped with spraying, fruit selection, and self-contained lifting equipment, which is convenient to connect with the production line.

The fruit and vegetable bubble cleaning machine equipment is suitable for the cleaning of fruit and vegetable raw materials, especially for the cleaning of soft fruit and vegetable raw materials. The washing water is filtered and recycled, which consumes less cleaning water. The cleaning machine materials are slowly rinsed in the water through the mesh belt. The discharge end is equipped with spraying, fruit selection, and self-contained lifting equipment, which is convenient to connect with the production line.

The working principle of bubble cleaning machine

The cleaning of the fruit and vegetable bubble cleaning machine is to use a blower to send air into the washing tank, so that the water for cleaning the raw materials is violently turned. Due to the violent agitation of the air on the water, the turbulent water flow washes the surface of the material to wash the dirt. The use of air for stirring can speed up the cleaning of dirt and prevent the raw materials from being damaged under strong turning, so it is suitable for the cleaning of soft fruit and vegetable raw materials.

The fruit and vegetable bubble cleaning machine is composed of a mesh belt conveyor, a spray washing device, and a water collection tank. The lower part of the mesh belt conveyor is immersed under the water surface of the washing tank, and the blower outlet is connected from the side of the conveyor belt with the blowing tube in the middle of the conveyor belt. There are many small holes on the blowing tube, and the air sent by the blower passes through the blowing tube. The small holes in the middle are blown out, and the water is violently turned through the mesh belt. When working, the washing tank is filled with washing water, the motor drives the driving drum to make the mesh belt run, and the blower is also started. The cleaned materials are put into the lower horizontal section of the conveyor. In the washing tank, due to the violent stirring effect of the air sent by the blower on the water, the dirt on the surface of the material is washed away, and then as the conveyor belt moves, the material is brought to the inclined section of the conveyor belt, and the inner spray pipe performs God wash for the last time. After that, it enters the upper horizontal section and sends it to the next process after the last inspection.

Characteristics of the vegetable washing machine

The fruit and vegetable bubble cleaning machine is suitable for: cleaning, soaking, sterilizing and color fixing of granular, leaf and rhizome products such as leafy vegetables, edible fungi, fruits, aquatic products and Chinese herbal medicines.

- The equipment is made of stainless steel SUS304 except for standard parts such as motors and bearings, which fully meets the requirements of export food hygiene.Under the combined work of bubbles, surfing, lifting, and spraying, the equipment has the characteristics of high cleaning, energy saving, water saving, stable and reliable equipment, and maintaining the original color. It is an ideal equipment for vegetable, food processing, catering and other industries.

- The equipment is equipped with a bubble generating device to make the material in a tumbling state, which has the effect of removing pesticide residues on the surface of the product. At the same time, an appropriate amount of medicament can be added for disinfection and fixation. Floating matter can overflow from the overflow tank, and the sediment is discharged from the sewage outlet to achieve the purpose of cleaning.

- The conveying part of the machine adopts SUS304 stainless steel mesh belt, which has the characteristics of stable operation and long service life, which meets the requirements of food hygiene.

- The operation is simple, the maintenance is convenient, and the connection is convenient.

- The main stainless steel of the sink of this machine is made of 2mm thick 304 stainless steel.

Related Content

High Quality Industrial Vegetable Cutter for Sale

Efficient Onion Cutter Machine for Restaurants

Discover the Perfect Machine for Cutting Vegetables Automatically

Types and Uses of Industrial Vegetable Dicer

Should We Wash Eggs with Commercial Egg Washer?

What Are the Applications and Functions of Commercial Vegetable Dicer?

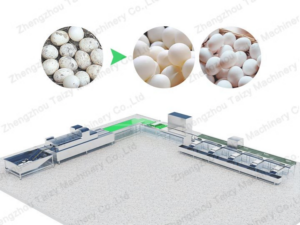

Egg cleaning machine for washing eggs

Principle of vegetable washing machine

Potato washing machine sold to Pakistan