Production process of soybean oil press

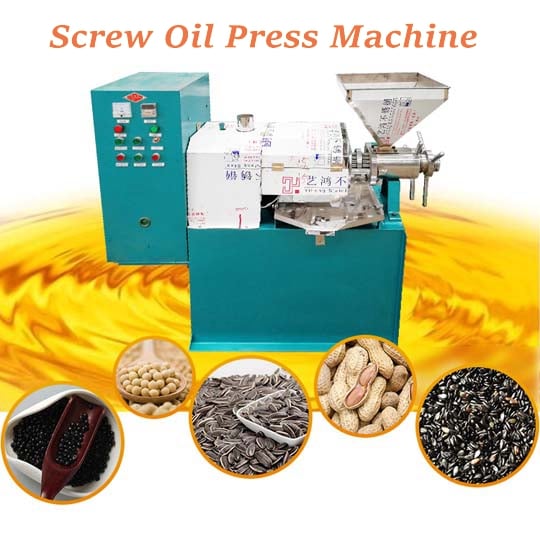

Soybean oil presses are commonly referred to as the screw type automatic oil press machine. These oil presses work very efficiently and the quality of the soybean oil is very good. The screw oil press is manufactured using domestic advanced technology, and the main structure is divided into two parts: the spiral structure and the…

Soybean oil presses are commonly referred to as the screw type automatic oil press machine. These oil presses work very efficiently and the quality of the soybean oil is very good. The screw oil press is manufactured using domestic advanced technology, and the main structure is divided into two parts: the spiral structure and the squeeze cavity. This commercial oil expeller machine has been widely exported to Malaysia, Kenya, South Korea, and other countries.

How is the production process of the soybean oil press?

Soybeans are low-oil crops and generally have a soybean oil content in the range of 1% -20%. Under normal circumstances, the moisture content of soybeans is generally 13% -149%. Soybeans need to be sieved and removed with a sieve before pressing. The specific process of using an oil press to produce soybean oil is as follows:

- Hot pressing:

Main processing craft: Soybeans—clearing and crushing (or rough rolling)—softening—rolling embryos—steaming frying—and pressing

Operating instructions of the commercial screw oil press: Soybeans should be sieved with a mesh size of 12 mesh/inch to remove impurities so that the impurity content is less than 0.1%, and then crushed to a degree of crushing of 24 mesh, and then softened. Keep the moisture content of soybeans at about 15% and the softening time of 40-50 minutes. After that, the embryo is rolled. The role of the rolled embryo is as follows: First, it destroys the cell tissue and makes the oil easily from the cell.

The internal flow comes out. The second is that the granular oil will be rolled into thin sheets with a large surface area, which increases the oil output area, and greatly shortens the distance that the oil leaves the blank. Then put the blanks in a wok for steaming and frying, steaming until the soybean moisture is in the range of 1.5% -2.8% when the temperature reaches 100-110 ° C, it can begin to enter the oil press for pressing. The thickness of the dough cake should be controlled at about 1-1.5 mm.

2.Cold pressing:

Soybean cold-pressing uses a hydraulic oil press for whole-seed pressing. When the whole seed is pressed, the moisture of soybeans should be strictly controlled, generally controlled at about 8% -10%, and the oil press should be heated, and the soybean oil can be pressed when the standby temperature rises to about 80 ° C.

Problems may be encountered in using screw soybean oil press machine

When using a screw press to squeeze soybean oil, whether cold or hot pressed, due to improper operation or improper adjustment of the water content of the oil, different problems will occur.

- Slag running occurs during pressing. The soybean oil press is normal (up to 5%) if there is a small amount of slag running when pressing the oil. If the amount of slag running is large, it needs to be adjusted. From the perspective of the oil material, the oil material has an improper moisture content, too dry or too wet, slagging will occur. The oil material is too wet, the slag is flaky, the cake is soft, and it can be held into a lump by hand, and the oil flows There was white foam in it. If the oil is too dry, the slag strips will be powdery, the crumb cake will turn white into powder, and the oil will not flow smoothly.

- Oil return occurs when pressing soybeans. That is, there is oil in the hopper. Oil return rarely occurs when pressing soybean oil, because oil return is a phenomenon that is easy to occur when pressing high oil content oil. This may be the reason for the strip gap being too small. You should use a mat to adjust the strip clearance of the screw oil press machine. In addition to adjusting the strip clearance, you must loosen the compression nut to increase the strip drainage oil gap.

- Soybean oil press does not feed or cake. It is mainly caused by improper use without running-in when the new machine is first used. It should be adjusted when the moisture content of the oil is improper. When using the new machine, you should strictly follow the instructions.

Related Content

Exporting Hydraulic Oil Press Machine to Canada

Automatic sesame hydraulic oil press

What kind of oil press machine does a small oil mill need?

Oil press machine for sale South Africa with a good price

Oil Filter | Centrifugal Oil Filter | Cooking Oil Filtering

Screw Oil Press | Oil Expeller