How to maintain bubble vegetable washer?

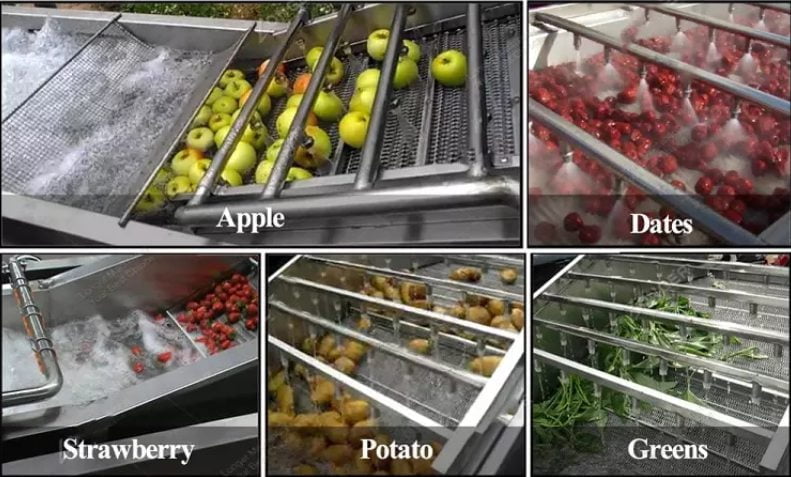

Industrial bubble vegetable washers are often used in food processing plants to continuously clean various vegetables and fruits, such as cabbage, tomatoes, strawberries, carrots, apples, potatoes, etc. When using the bubble vegetable washing machine, in order to improve its work efficiency and extend its service life, we must master the maintenance methods of the bubble…

Industrial bubble vegetable washers are often used in food processing plants to continuously clean various vegetables and fruits, such as cabbage, tomatoes, strawberries, carrots, apples, potatoes, etc. When using the bubble vegetable washing machine, in order to improve its work efficiency and extend its service life, we must master the maintenance methods of the bubble washer.

The working principle of bubble vegetable washing machine

When using the vegetable washing machine, first put all the vegetables to be washed into the sink. Then turn on the air pump to generate high-pressure airflow. Under the action of high-pressure water flow and powerful air bubbles, the vegetables are fully broken up, rolled, washed, and transported.

The mud and sand on the surface of the vegetables will fall off and settle to the bottom isolation bin, preventing re-pollution caused by backflow. The debris and bugs washed from the vegetables will float on the water, then be collected by the mesh, overflow the sink and enter the nylon bag. After the vegetables are cleaned by the washing machine, they are washed by spray and then sent out through the conveyor belt.

The maintenance tips of industrial bubble vegetable washers

The automatic bubble cleaner is made of SUS304 stainless steel, which meets the national food export standards. The vegetable washing machine adopts high-pressure spray cleaning, which has a large cleaning capacity, a high cleaning rate, and does not damage the materials. It is especially suitable for cleaning foods with many impurities and difficult to remove stains.

The industrial bubble vegetable washer is suitable for cleaning, removing impurities, and conveying materials such as stem vegetables, fruits, and Chinese herbal medicines. It replaces heavy physical labor and realizes the automation of agricultural products processing.

Timely maintenance and upkeep of vegetable washing machine after use is very important to the equipment. Users can check and maintain bubble vegetable washer machine regularly according to the following methods:

- The maintenance of the vegetable washing machine must first turn off the power switch so that the equipment is in the shutdown state and the maintenance work is performed.

- Belt adjustment: In the middle of the two pulleys, the compression amount of the belt pressed by the fingers (middle finger and index finger) is 7-12mm as the standard value. When it is greater than the standard value, adjust the idler pulley to the specified tightness.

- Chain adjustment: Press the chain with your fingers (middle finger and index finger) in the middle of the two sprockets. The compression amount is 4-9mm as the standard value. When the standard value is exceeded, adjust the idler to the specified tightness.

- Attention should be paid to the regular inspection, refueling, and replacement of the gearbox oil. Remove the oil plug under the condition of strictly prohibiting fire and smoke. The oil has just flowed out to an appropriate amount and should be refilled in time when it is insufficient.

Related Content

High Quality Industrial Vegetable Cutter for Sale

Efficient Onion Cutter Machine for Restaurants

Discover the Perfect Machine for Cutting Vegetables Automatically

Types and Uses of Industrial Vegetable Dicer

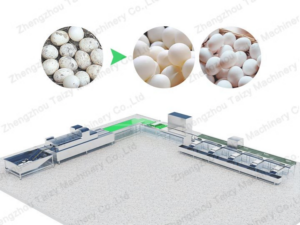

Should We Wash Eggs with Commercial Egg Washer?

What Are the Applications and Functions of Commercial Vegetable Dicer?

Egg cleaning machine for washing eggs

Principle of vegetable washing machine

Potato washing machine sold to Pakistan