Which kind of heating method is good for a jacketed cooking kettle?

The industrial jacketed cooking kettle is a multifunctional food processing equipment. It can also be called a steam pot, cooking pot, or a frying pot. The sweets, pastries, candied fruits, canned food, lozenge and so on we usually eat can be processed using this jacketed cooking kettle. This practical food cooking pot is a common device for…

The industrial jacketed cooking kettle is a multifunctional food processing equipment. It can also be called a steam pot, cooking pot, or a frying pot. The sweets, pastries, candied fruits, canned food, lozenge and so on we usually eat can be processed using this jacketed cooking kettle. This practical food cooking pot is a common device for various food processing plants to improve product quality, improve production efficiency, shorten processing time, and reduce production costs.

Main features of the jacketed cooking kettle

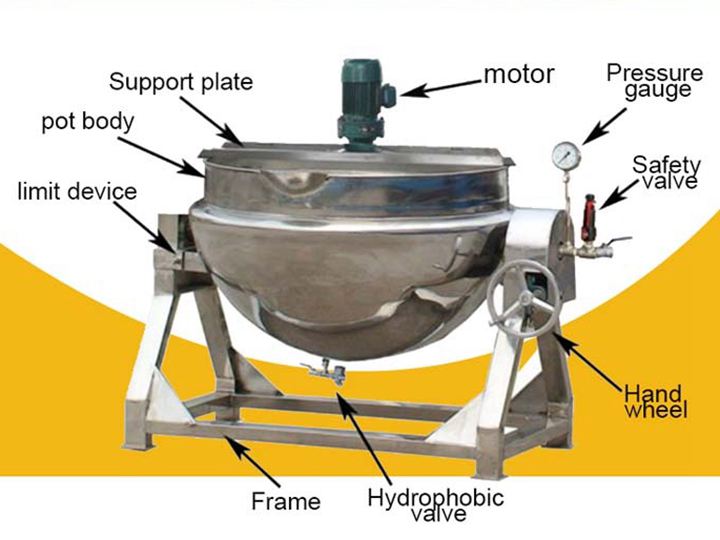

The jacketed cooking kettle is mainly composed of a pot body, a frame body, a stirring system, a heating system, a speed regulating transmission device, a stirring shaft, and a pot body turning system. Its stirring method uses a special inclined planetary transmission to make the agitator and the pot fully contact. The non-integer transmission ratio of transmission revolution and rotation is realized, thereby ensuring that there is no dead corner in the pan, the materials are uniformly stirred, and the pan is not sticky.

The main applications of the electric jacketed kettle pot

The commercial jacketed kettle for cooking can be widely used in the production of various kinds of candy, lotus seed, bean paste, jam, pastry, beverage, candied fruit, canned food, date puree, sauce, curry, seasoning and daily chemical, pharmaceutical and other industries. , As well as pharmaceutical, dairy, alcohol and other food processing.

Which kind of heating method is good for a jacketed cooking kettle?

There are three types of heating methods for jacketed cooking pots: electric heating jacketed cooking pots, steam heating jacketed kettles, and gas heating cooking pots.

- Electric heating jacketed cooking kettle

This heating method mainly uses a heating pipe to heat the heating medium (water or heat-conducting oil), and then the heating medium transfers heat to the inner layer to heat it. This is called an electric heating jacketed cooking pot. It is relatively simple and convenient to use, as long as it has three-phase power.

- Gas heating jacketed cooking pot

This heating method mainly uses a gas furnace (need natural gas or liquefied petroleum gas) to heat the jacketed heating medium (water or thermal oil), and then the heating medium transfers heat to the inner layer to heat it. This is called gas heating cooking pot.

- Steam heating jacketed kettle

This heating method mainly passes the steam generated by a steam generator or a steam boiler to the jacket of the jacketed pan, and heats and transmits the temperature to the inner layer. This is called a steamed jacketed pan. This method of heating usually requires a steam generator and a steam boiler.

Analysis of advantages and disadvantages of three heating methods of jacketed cooking kettle

- The advantage of electric heating is that it is economical, but the heating speed is slightly slower than steam heating. It can realize pressureless heating. The heating temperature depends on the boiling point of different heating media.

- The steam heats up quickly for the jacketed cooking kettle. Generally, it takes about half an hour to heat the water at normal temperature with a steam generator or a steam boiler, which consumes slightly more fuel. Generally, large food processing plants choose to use steam for heating.

- Gas-fired jacketed kettles are generally used because the power of the plant is not enough, so they can be solved by gas heating. Gas heating is slower than steam and electric heating pipes.

Related Content

Steam Jacketed Pans: Uses, Benefits, and Types

Two Electric Jacketed Kettles shipped to Vietnam

Exploring the Varied Types of Commercial Cooking Kettles

Steam Jacketed Help Dubai Food Factory Make Peanut Candy

Steam Jacketed Kettle for Sale

How is the jacketed kettle price? Jacketed kettle with agitator for sale

300L steam jacketed kettle cooker shipped to the Philippines

Russian customer ordered two commercial jacketed kettles