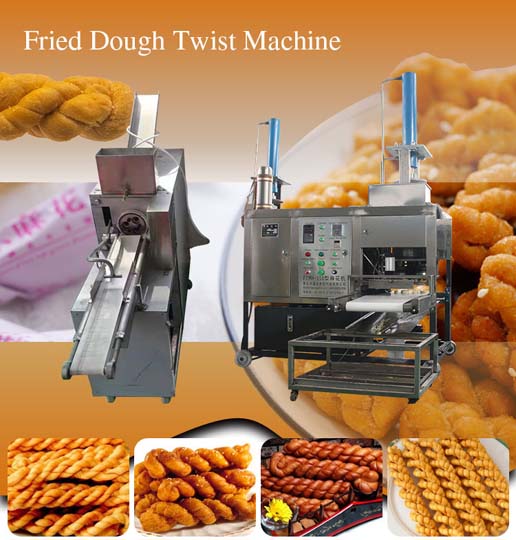

Fried Dough Twist Machine | Mahua Maker

Fried dough twist also named Mahua is a specialty health food in China. The golden twist is sweet and crisp, delicious and not greasy, rich in protein, amino acids, multivitamins, and trace elements. Mahua is a kind of dough twisted together by two or three strips or more strips, then be cooked by frying. We can make the fried dough twist by hand or make it with a special fried dough twist machine. The fried dough twists with moderate calories and low fat are ideal snack foods that are now popular in countries around the world like Korea, the Philippines, and Vietnam.

Dough twist maker machine working video

Automatic fried dough making machine description

The fried twisting machine belongs to a common food processing equipment, and can also be said to be a food semi-processing equipment. Its main job is to replace the artificial dough twisting and molding equipment of various styles. In the actual production of fried dough twists, this machine usually should match with a dough mixer, a frying machine and a seasoning machine for doing delicious Mahua production. According to different requirements of the final fried dough twists, our fried dough twist maker mainly can make the fried dough twists with single-strip, three-strips, and six-strips.

How to make fried dough twists?

The fried dough twists making machine can be different types and models, which mainly can be divided into three types: single-strip fried dough twist machines, hydraulic type three-strips fried dough twist maker and hydraulic type six-strips fried dough twist machine.

Single-strip fried dough twist machine

The single-strip fried dough twist processing machine is the simplest type of mahua making machine, which is composed of the frame body, PLC controlling system, dough extracting part and the dough twists cutting and discharging part.

- Frame body: The frame body is made of 304 stainless steel welding.

- Control system: PLC control system.

- Molding part: feeding with screw drive, driving the planetary wheel system to rotate and discharge.

- Cutting and discharging parts: consisting of a belt structure of a conveyor belt and a charged disk.

Main features: The fried dough twists’ thickness and the length can be adjusted easily.

Technical parameter:

| Model | Output | Voltage | Power | Weight | Dimension |

| TZ-20 | 10KG/H | 220V/380v | 0.75kw | 100kg | 1200*630*750mm |

Hydraulic type fried dough twisting machine

The hydraulic type fried dough twist maker machine mainly includes the three-strips and six-strips fried dough twists making, which is more efficient than the first type, and their output is larger. Besides, this kind of mahua making machine is composed of the frame body, PLC controller, hydraulic system, dough twisting part and the discharging part. The hydraulic system includes the automatic cutter and the air compressor.

Three-strips fried dough twist machine

Technical parameters:

| Model | Output | Voltage | Power | Weight | Dimension |

| TZ-150 | 50KG/H | 380V | 5kw | 400kg | 1200*630*750mm |

Six-strips fried dough twist machine

Technical parameters:

| Model | Output | Voltage | Power | Weight | Dimension |

| TZ-300S | 150KG/H | 380V | 6kw | 500kg | 1500*1300*1800mm |

Main features of the hydraulic fried dough twists maker

- The PLC controller can heat the dough of the inlet barrel automatically so that can make sure to keep the flexibility of the dough for making fried dough twists, especially in winter when the dough is easy to frozen.

- The final fried dough twists’ thickness and length can be adjusted easily to meet the customers’

- This fried dough twist machine is set an automatic oil drip device that can automatically fill oil into the dough twists to prevent the dough from sticking together.

Fried dough twist making machine use and maintenance

- Fill the gears and lubrication parts of the machine before and after turning on the machine (external butter, internal cooking oil). After turning on the power, first, check if the direction of the machine is running correctly, and then listen to the machine for abnormal sound. If there is abnormal noise, stop the machine and have a check.

- Brush the fried dough making machine’s cutter with cooking oil to avoid sticking the knife. The dough is automatically cut by a cutter on the conveyor belt, and the twisted end of the dough twists can be flattened while being cut. In this way, the twisted ends of the fried dough twists will not spread when frying. After the dough twist is cut, it can be fed into the oil pan through the conveyor belt for frying.