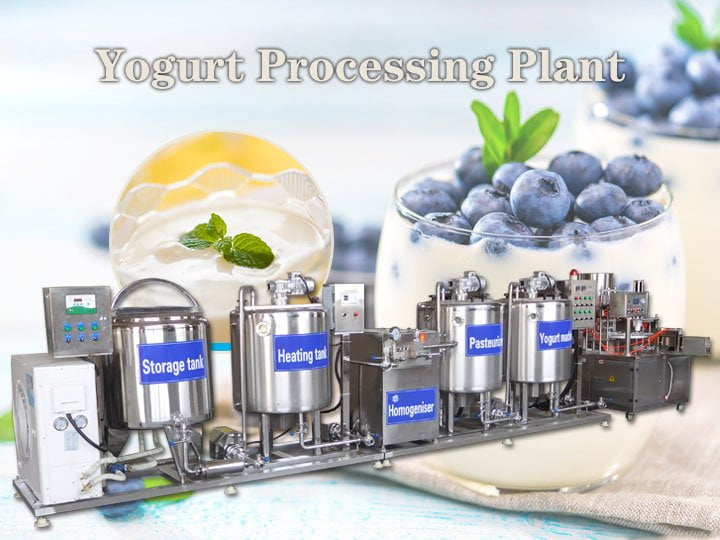

200-500L/D Yogurt Production line | Yogurt Processing Plant

The compact yogurt production line can also be called yogurt processing line, yogurt processing plant, small-scale yogurt production line, which mainly can process all kinds of milk into plain yogurt and fruits-based yogurt. These yogurt processing machines include a series of milk processing crafts, such as fresh milk storage, milk filtering, milk preheating, milk homogenizing, milk sterilizing, milk fermenting and yogurt packing.

The main difference between pure milk and yogurt?

Yogurt is a semi-fluid fermented dairy product that has a mild acidity due to its lactic acid content, which helps the body better absorb and absorb the nutrients in milk. Yogurt is a kind of dairy product that uses fresh milk as raw material, pasteurized and then added beneficial bacteria (fermenting agent) to milk, and then fermented and then cooled.

At present, the yogurt products on the market are mainly composed of fruit-type yogurt which is solidified, stirred and added with various juice jams and the like. Yogurt not only retains all the advantages of milk but after processing, yogurt is rich in various beneficial bacteria, making it a more suitable nutrient for humans.

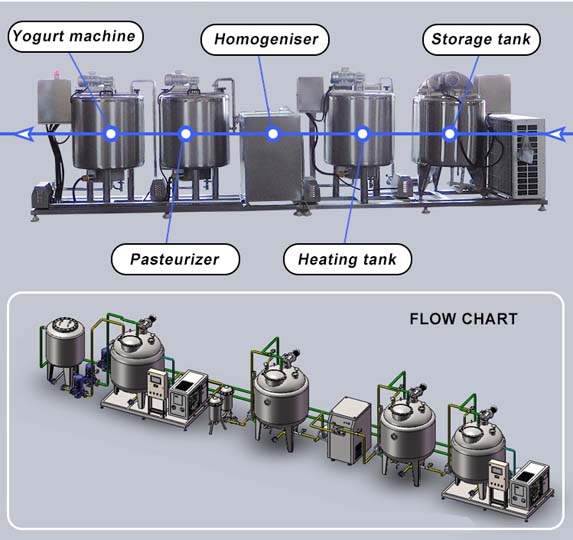

How the yogurt is made through the yogurt production line?

Step 1: fresh milk keeping and filtering

Pour the fresh milk used to make the yogurt into the milk storage tank for cryopreservation with a temperature of 3-6℃. There is a matching compressor next to the milk storage tank to provide a low-temperature environment for the milk storage. The setting electric cabinet can be used for monitoring and adjusting the milk storing temperature to avoid milk deterioration. There is a filter between the milk storage tank and the milk preheating tank, which can filter the milk entering the preheating tank to remove impurities from the milk.

Step 2: milk preheating

Open the regulating pump of the milk preheating tank, so that the filtered milk from the storage tank will be transported into the preheating tank through the connected stainless steel pipe. The milk preheating tank has a double-layer structure, and the water in the interlayer will be heated by electricity. The hot water temperature of the preheating tank is about 60℃, and the milk will be heated with a temperature of 45℃in in several minutes. When the preheating is finished, the power supply can be turned off automatically.

Step 3: milk homogenizing

The milk homogenizing machine can make the milk refine and fully mix under the triple action of extrusion, strong impact and pressure loss expansion, which can ensure the stability of the milk. The milk homogenizer is important equipment for emulsification, homogenization, and dispersion of milk. Turn on the conditioning pump of the milk homogenizing machine and the preheated milk will be pumped into the storage tank of the homogenizer. The milk homogenizing tank outlet has a lot of pressure to quickly homogenize the milk flowing through. The homogenized fresh milk will automatically enter the milk sterilization tank.

Step 4: milk sterilizing

After homogenizing, the milk will be stored in the milk sterilizing tank for further sterilization. The milk pasteurizer is also a two-layer structure. The heat transfer medium in the sandwich tank is heat transfer oil or water. When sterilization is required, the centrifugal milk pump connected to the homogenization tank and the pasteurization tank is opened and pasteurized by 350# heat transfer oil or hot water. The sterilization time in this milk sterilizing tank is generally about 0.5 to 1.5 hours, and the pasteurization temperature is 85℃.

Step 5: milk fermenting

Before the milk fermenting, we must first lower the temperature of the milk in the sterilizing tank to about 50℃. After the sterilization is completed, open the water inlet faucet at the bottom of one side of the sterilization tank, and the cold water will enter the interlayer of the pasteurization tank for fast cooling. Through the flowing cold water in the interlayer, the temperature of the milk in the retort will gradually drop to about 50 °C.

After the cooling is completed, turn on the milk regulating pump to allow the sterilized milk to enter the milk fermenting tank. Then adding the strains for fermentation to the milk fermenting tank. In the milk fermentation tank, the milk will be fermented within 8 hours with a temperature of 43℃.

Step 6: yogurt packaging

After the yogurt is fermented, we can use a filling machine to dispense the prepared yogurt. Open the air compressor switch to ensure the pressure inside the filling machine. Then turn on the conditioning pump of the fermentation machine to get the yogurt into the filling machine. When the filling machine barrel enters a certain amount of yogurt, turn off the conditioning pump and turn on the filling machine to heat the yogurt. When heated to 200 ° C, press the filling start button to fill the yogurt.

How to clean the yogurt processing plant?

When the yogurt production is finished, we should do the clean of the whole yogurt production line to make sure the cleanliness of the yogurt processing machines and ensure the yogurt quality for the next production. For cleaning these yogurt machines, there are two ways can be chosen:

- separately clean each of the machines in this line: we can add the water to each of the machines in this yogurt production line and start the machine for running, then discharge the wastewater.

small-scale yogurt production line - Use the CIP washing system for cleaning: Add hot water, acid water, and alkaline water to the refrigerating tank at the same time and start stirring. After the cleaning is completed, the regulating pump is turned on and the hot water enters the preheating tank. Turn on the stirring of the preheating tank, clean it, and turn on the homogenizer switch for cleaning. According to the production process of the whole yogurt production line, the sterilization tank and the fermenter are sequentially cleaned. Finally, the sewage is discharged from the sludge discharge port of the fermenter, and the cleaning is completed.

Main features of the commercial yogurt production line

- All these yogurt processing machines including these connecting pipes in this automatic yogurt processing plant are made of high-quality stainless steel, so that they are very durable, resistant to corrosion and abrasion and have a long service life.

- Each of the equipment in this line is designed with the adjustable feet which can be adjusted with the proper height for good yogurt production. When shipping the whole line of yogurt machines, we can separate it into two parts with the wooden-box and well-connecting the two parts of the machines. So that it will be very easy for the customer to install the yogurt processing plant.

packing and shipping of the yogurt processing machines - For full-automatic production with this yogurt processing line, we can provide the overall electric control cabinet for controlling and monitoring all the works of these yogurt processing machines. Besides, we can also provide a series of supporting devices and spare parts to assist your yogurt making. This yogurt processing plant can make 200L-500L per day, and if you want to make yogurt with a larger yield such as 1000L per day, we can also provide you the proper yogurt processing lines.

yogurt with different flavors