Screw Press Juicer Machine

The screw press juicer machine also named the dewatering screw press, which is the common type of juicer machine used in many fields. This commercial juicer machine can be of different types, such as the single-screw press, twin-screw juicer, and the special type of juicer machine. This screw press can be widely used for making fruit juice, distiller grains, and sawdust press dehydration, sewage, and dewatering of sludge and kitchen waste.

What is the screw press juicer machine?

This machine can be used for solid-liquid separation processing of certain fibrous or viscous materials. For example, fermented grape skin residue, ginger, spinach, rubber, Chinese herbal medicine, winter jujube, and other fruits and vegetables containing certain fibers can also be used for continuous juice extraction of sea buckthorn fruits except for branches or small branches.

The machine’s mesh can be customized to the size of the material. This juice press machine can also be used in environmental protection industries, such as press and dewatering of market waste and kitchen waste.

How does the dewatering screw press work?

When the fruit juicer machine is working, the material enters the crushing box through the inlet of the machine. Then the broken rod in the feed port quickly breaks the material by rotating at a high speed. The broken material is screwed into the press. The conveyor screw of the press will push the material entering the bin towards the pressing screw.

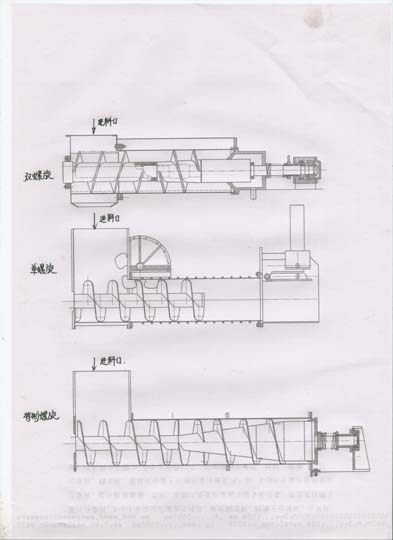

The pitch of the pressing screw is reduced and the shaft diameter is increased, and under the action of the screen wall and the resistance of the cone, the liquid (or juice) contained in the material is quickly extruded. The extruded liquid flows out of the sieve opening on the outside of the press and is concentrated in the juice hopper.

The pomace after pressing is discharged outside the machine through the end of the sieve cylinder and the cone. The rear of the cone of the machine is fitted with a spring. The pre-tightening force and position of the spring can be adjusted to change the discharge resistance and the size of the slag opening, thereby adjusting the dryness and wetness of the pressed fruit slags. The feeding box, sieve cylinder, and spiral of the machine are made of high-quality acid and alkali-resistant 304 stainless steel.

Classifications of the screw press dewatering machine

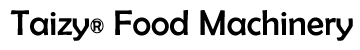

According to the different inner structures of the screw press, and their different applications for juicing and dewatering, the commercial screw press juicer machine can be divided into two types: the single-screw press, the twin-screw juicer, and the special type of screw juicer.

Single-screw press juicer machine

The single screw press has a single-spiral structure inside. It is a pressing device with a spiral and a spindle rotating in the same direction. It is suitable for pressing materials containing fewer plant fibers and relatively smooth surfaces, such as pressing vegetables and fruits such as grapes, berries, cabbage, melon, aloe, and the press of oil residue.

Single-screw continuous juicer machine applications

- All kinds of Chinese medicine slag (sticky after fermentation is unsuitable).

- A variety of vegetables and fruits, fresh grape skin residue and fermented grape skin residue, sea buckthorn fruit, pineapple and other juices containing certain fiber and vegetables, plant stems, and roots, such as corn stover dehydration.

- Undigested garbage and domestic garbage in the vegetable market.

- Medical plastic waste and various Chinese medicine slag.

- 100% fiber pulp residue, sawdust, wood chips, crude (cotton) fiber black juice extraction.

Technical parameter

| Model | TZ-1 | TZ-2 | TZ-3 | TZ-4 | TZ-5 | TZ-6 |

| Power(kw) | 4 | 4 | 7.5 | 15 | 18 | 22 |

| Output(t/h) | 1.5 | 3 | 5 | 10 | 20 | 40 |

| Dimension(mm) | 2565*480*905 | 3200*560*1120 | 4100*900*1500 | 4620*920*1550 | 4950*1100*1730 | 6000*1200*2000 |

| Weight(kg) | 800 | 1200 | 2000 | 2500 | 3000 | 4500 |

Above are the parameter details of single screw press juicer machine. You can know the power, output, size, and weight of the machine according to the parameter table. If you need, please feel free to contact us.

High-efficient twin-screw juicer

The structure of this twin-screw juicer machine is different from that of a single screw press, and its application range is also different. The machine has two spirals in series on its internal shaft, and the two spirals rotate in opposite directions. They work like a “tumble towel” and can be fully pressed.

The double-screw press is suitable for the fermentation of grape skin residue, sea buckthorn fruit, ginger, and other fruits and vegetables after fermentation. It is the most favorable press in price at present, and due to its high pressing rate for the materials, its output is relatively small.

The materials are not suitable for pressing with the twin-screw juicer

- Contains fluid and slippery materials.

- Fruits and vegetables with particles less than 10mm and containing sugar.

- Chinese medicine slags with particles larger than 10mm.

Technical parameter

| Model | TZ-S1.5 | TZ-S5 | TZ-S10 |

| Power(kw) | 7.5 | 7.87 | 11.37 |

| Output(t/h) | 1.5 | 5 | 10 |

| Dimension(mm) | 1900*600*1200 | 3500*1000*1300 | 3750*960*1300 |

The output of the twin screw juice extractor is 1.5-10t/h. The power of the machine is between 7.5kw and 11.37kw. Do you need an efficient twin screw press juicer machine to help you? Feel free to contact us through the pop-up window in the lower right corner.

The special-made screw juicer machine

This type of juicer machine is also named the variable-diameter screw press. The machine mainly through the change of the diameter of the screw shaft to complete the material pressing and dewatering work with a continuous role in the crushing of materials. Its discharging mode is discharging in all-round directions.

This screw type juice making machine is suitable for materials with a particle size of 2mm or more and 10mm or less (the liquid material is most suitable), and the smaller the particle size, the higher the dewatering rate, and its minimum gap of the sieve barrel can be 0.2mm-0.3mm.

Applications range of the special screw press machine

This special screw press is suitable for dense, smooth, fermented, viscous, liquid materials containing colloidal protein oils and fine fibers. The pressing of these materials is roughly divided into the juice extraction of fruits and vegetables and the roots and leaves of fruits and vegetables, the juice extraction of various waste residues, the dehydration of pulp residue, the dehydration of garbage, and the dehydration of feces.

Technical parameters

| Model | TZ-1-1 | TZ-1-2 | TZ-1-3 | TZ-1-4 | TZ-1-5 | TZ-1-6 |

| Power(kw) | 4 | 7.5 | 15.5 | 18.5 | 22 | 30 |

| Output(t/h) | 0.8-1 | 1.5 | 3 | 5 | 10 | 20 |

| Dimension(mm) | 1950*510*740 | 2400*600*1100 | 4100*850*1500 | 4900*920*1700 | 5200*1000*1870 | 6500*1200*2000 |

| Weight(kg) | 230 | 1200 | 2400 | 3000 | 3700 | 5000 |

We have 6 models of special screw press machines for customers to choose from. You can process 0.8-20t of material per hour with this machine.