Commercial Yogurt Maker | Fermentation Machine

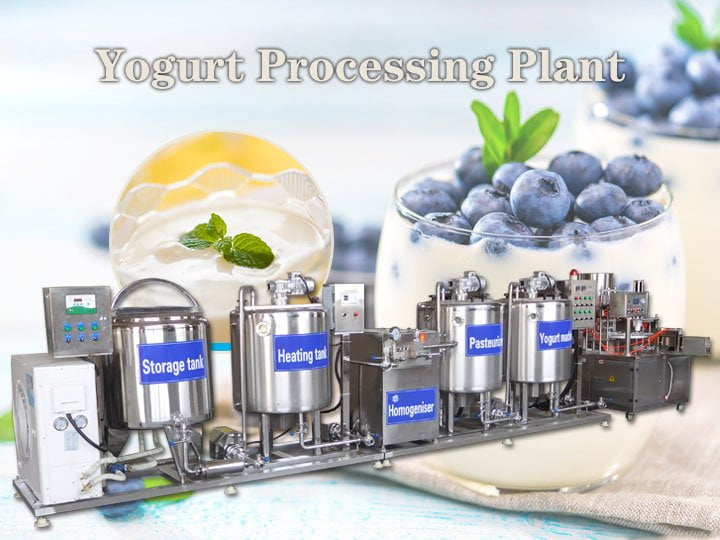

The Yogurt Maker also can be called a yogurt fermentation machine, yogurt machine, commercial yogurt maker, and yogurt making machine. It is the electric yogurt processing equipment for making plain yogurt, thick yogurt, and fruit-based yogurt through 8 hours’ fermentation process with a temperature of 43℃. Besides, the commercial yogurt machine has four functions sterilization, fermentation, cooling, solidification, and refrigeration to make fresh milk into solid yogurt. It is suitable for most of the fast-food stores drinks stores and bakeries.

What is the commercial yogurt maker?

The commercial yogurt machine is a designed yogurt maker with the electric heating method, which can provide the appropriate fermentation conditions for sterilized milk fermenting. The milk for making yogurt is mainly fresh milk, like goat milk, cow milk, and horse milk. Before milk fermentation, this fresh milk should be sterilized at the temperature of 85℃first to kill most of the bacteria in the milk. When the yogurt fermenting is finished, this yogurt maker will turn to the refrigerated storage temperature of about 4℃automatically.

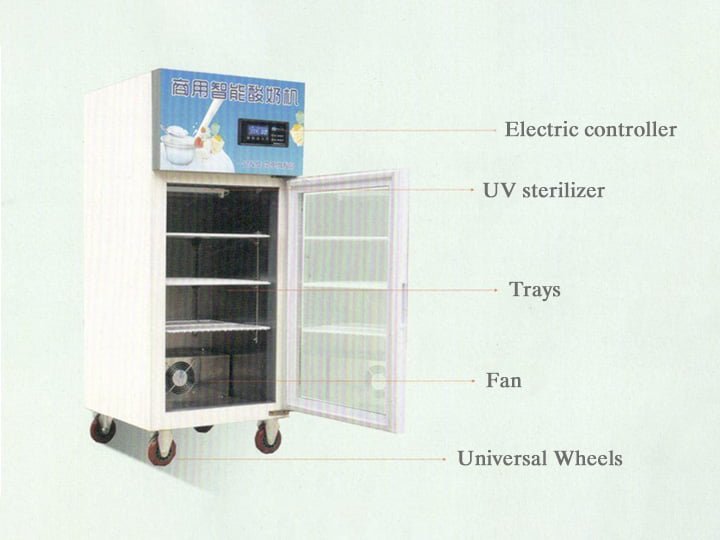

The main structure of the yogurt fermentation machine

From the outside of this yogurt maker, it looks like a big cabinet with a transparent glass door and inner storage racks. This yogurt fermenter is an intelligent temperature control chamber for yogurt fermentation and cold keeping. It is composed of a compressor, exhaust fan, radiator, digital display, sterilization lamp, temperature sensor, body casing, and universal wheels. The chamber is equipped with trays and grids for holding the separate yogurt cups. For meeting different requirements of the customers about yogurt production, this yogurt machine can be designed with the single-chamber type and the double-chamber type.

Main classifications of the yogurt maker

1. Single-chamber yogurt machine

This type of yogurt processing machine is very suitable for small drink stores or retail stores for providing fresh yogurts. It has one fermentation chamber and one glass door, and its volume is about 176L and the yogurt yield is 50-100L per 8 hours. The body casing of this single-chamber yogurt maker is made of stainless steel so that it is resistant to wear and tear.

Parameters:

Model: TZ-SNJ-388

Dimension: 65*70*195cm

Heating power: 1kw

Cooling power: 0.23kw

Fermenting temperature: 0-60℃

Cold keeping temperature: 0-8℃

2. Double-chamber yogurt maker

The double-chamber yogurt fermenting machine is a commercial type of yogurt processing machine, which is suitable for various restaurants, bakeries, fast food shops, cafes, and so on. It has two fermentation chambers so that its inner volume is larger than the single-chamber type of yogurt machine. Its plain yogurt yield in 8 hours is about 150L. It is also made of durable stainless steel and is easy to move with the universal wheels.

Parameters:

Model: TZ-SNJ-760

Dimension: 120*70*195cm

Heating power: 2kw

Cooling power: 0.3kw

Fermenting temperature: 0-60℃

Cold keeping temperature: 0-8℃

How the delicious yogurt is made by the yogurt fermenting machine?

- The fresh milk should be sterilized first with the special sterilization equipment at a temperature of 85℃ for about 10 minutes. Then when the temperature cools down to 45℃, pour about a pound of the yogurt fermenting strains into the container and mix well, then pour into a stirred tank, stir for 3 minutes, and let stand for 5-10 minutes.

- Dispense the milk from the mixing tank into dedicated small yogurt placing cups and drain the cups into the tray on the yogurt machine grid.

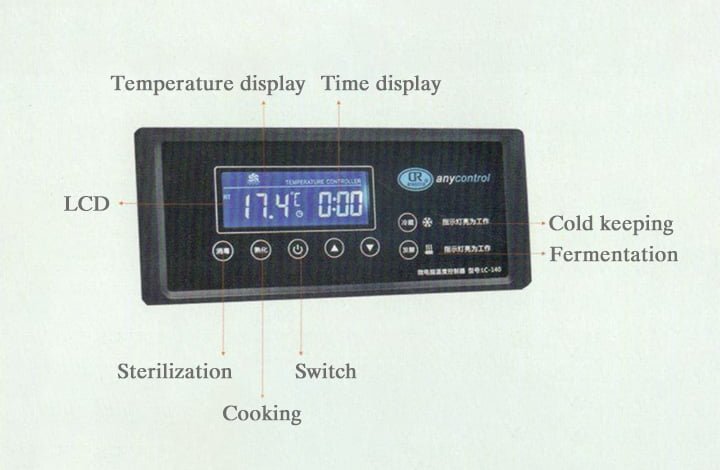

yogurt fermentation application inner yogurt making process - Start the yogurt maker and set the yogurt fermentation temperature to 42℃-43℃. Notes: Before using the yogurt machine, the yogurt machine’s console should be spray-sterilized with a 75% concentration of medical alcohol (if the bacteria is contaminated, the quality of the yogurt will be bad). After the alcohol spray, open the door for about 2-3 minutes to remove the alcohol smell, and then sterilize the sterilization lamp (the sterilization time is set at the factory).

- After 8 hours of yogurt fermentation, this yogurt maker will switch to low-temperature keeping automatically.

Precautions of the yogurt processing with the electric yogurt machine

- To protect the compressor, the compressor can be restarted after being stopped for 3 minutes under any working condition.

- When it is detected that the temperature sensor has an open circuit or short circuit fault for 3 seconds, it should stop automatically (open circuit fault flashes E4LL, short circuit fault flashes E4HH). The current working status indicator flashes and the buzzer will beep.

plain yogurt made by yogurt maker thick yogurt - The density of fresh milk is close to that of specific heat and water, which is nearly a thousand times that of heating the carrier air. Therefore, if you want to quickly heat the milk or quickly cool the yogurt, you must ensure that the air in the box is smooth. For this reason, the milk cup must not be placed too densely, the pile is too high, and there must be enough clearance between the cups.