Fully Automatic Pita Bread Production Line | Commercial Arabic Bread Making Machine

The industrial pita bread production line is a fully automated, integrated solution engineered for the mass production of soft Arabic pita bread and flatbread. This complete processing plant—which includes a dough kneading machine, a dough sheet press, a forming machine, and a continuous tunnel oven—delivers a production capacity of 100-500 kg/h (up to 2,000 pieces/hour). It is designed to produce a final product thickness of 1-2 mm and can be configured for various formats, including round (30-40 cm in diameter) and square (30*25 cm) bread. Constructed from food-grade 304 stainless steel and available with either gas or electric heating systems, the line directly solves key commercial challenges such as production bottlenecks and high labor costs. Both product size and overall output can be further customized, realizing a mechanized, energy-saving, and highly efficient production process that guarantees consistent quality.

Industrial Production Challenges & Our Solutions

Scaling pita bread production to an industrial operation presents distinct commercial challenges. Our engineering provides direct, data-driven solutions to these challenges, enabling a more profitable and reliable production facility.

Challenge 1: Production Bottlenecks & High Labor Costs

Manual production is limited by labor availability, speed, and cost, creating a ceiling on output and profitability. Our fully automated commercial pita bread machine addresses this by eliminating manual intervention at critical stages. This level of automation reduces labor dependency, minimizes training, and lowers long-term operational expenditure.

Challenge 2: Inconsistent Product Quality & Brand Risk

Inconsistency is a primary risk to a food brand’s reputation. Manual work leads to variations in product thickness, diameter, and cooking quality. The pita bread machine commercial line replaces this guesswork with precision engineering. Its adjustable pressure rollers (1-6 mm range) and a final product thickness control of 1-2 mm achieve parameterization. Every piece of pita bread is produced with identical specifications, safeguarding your brand’s reputation.

Challenge 3: Diverse Market Demands & Inflexible Production

The global market for pita bread is not uniform; different regions demand specific sizes and shapes. A rigid production line cannot adapt. Our system is engineered for adaptability. Interchangeable forming molds allow for switching between product types, including round (30-40 cm diameter) and square (30×25 cm) pita bread. This flexibility allows you to meet diverse market demands.

Core Modules of the Production Line: A Breakdown of the Engineering Process

Each module in the production line is engineered for a specific function, working in a synchronized sequence to guarantee efficiency and quality. The entire line is constructed from food-grade 304 stainless steel.

Step 1: Dough Mixer

The process begins with the dough mixer. Its internal shaft mimics manual kneading, a critical process that develops a robust gluten structure, resulting in a final product with improved texture and elasticity.

Step 2: Dough Sheet Press

The machine employs a multi-pass rolling process. This is an engineering step that improves the dough’s elasticity, creating a resilient flatbread that puffs correctly during baking.

Step 3: Forming Machine

This module performs two functions. First, its interchangeable molds cut the dough sheets into the final shape and size. Second, an integrated scrap dough recycling system collects and re-integrates off-cuts into the production flow, reducing raw material waste and increasing profit margins.

Step 4: Tunnel Pita Bread Oven

The continuous tunnel pita bread oven ensures every piece is baked uniformly. For higher volume requirements, output can be doubled with custom double-row configurations. The gas-heated option offers a cost-saving opportunity for large-scale producers where natural gas is a more economical industrial energy source.

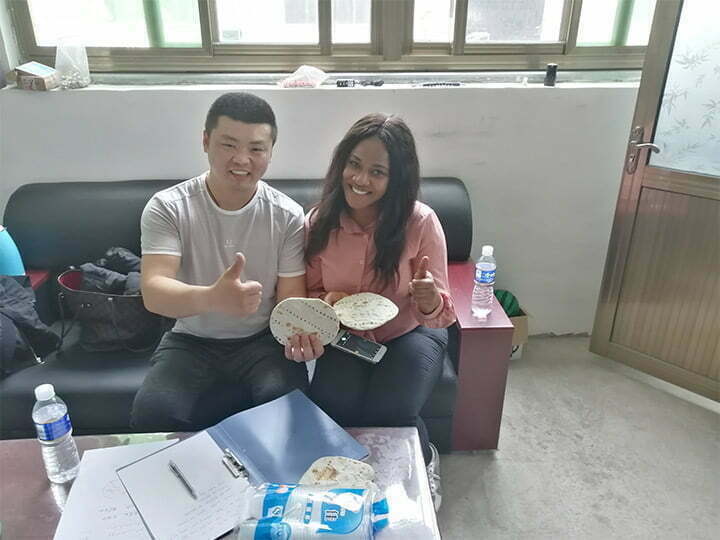

Global Client Validation: The Choice of Businesses in Turkey and the UAE

Our pita bread production lines are in commercial operation in several key markets, with proven success among food processors in Turkey and the UAE. These clients chose our equipment based on its reliability, efficiency, and the quality of the final product.

Complete Technical Specifications Sheet

This data sheet provides all necessary technical details for evaluation by your engineering and procurement teams.

| Module | Parameter | Value |

|---|---|---|

| Dough Mixer | Capacity | 50 kg/batch |

| Power | 2.2 KW | |

| Weight | 250 kg | |

| Dimensions (L×W×H) | 980 × 510 × 1010 mm | |

| Dough Sheet Press | Roller Width | 350 mm |

| Capacity | 350 kg/h | |

| Power | 3 KW / 4 KW | |

| Weight | 250 kg | |

| Dimensions (L×W×H) | 1330 × 615 × 1060 mm | |

| Pita Bread Forming Machine | Capacity | 1,000 kg/h |

| Power | 2.2 KW | |

| Weight | 300 kg | |

| Dimensions (L×W×H) | 1900 × 730 × 1100 mm | |

| Thickness Range | 1 – 6 mm | |

| Materials | Stainless Steel + PVC Food-Grade Conveyor Belt | |

| Pita Bread Tunnel Oven | Capacity | 800 pcs/h (baseline) |

| Belt Power | 1.2 KW | |

| Voltage | 220 V (customizable) | |

| Weight | 560 kg | |

| Dimensions (L×W×H) | 2650 × 830 × 1020 mm | |

| Heating Options | Electric / Gas |

A Strategic Investment in Your Commercial Success

In summary, our fully automatic pita bread production line is more than a set of machines; it is a strategic investment in your company’s scalability, standardization, and profitability. By solving core industrial challenges with robust engineering and data-driven performance, this system provides the foundation for sustainable growth and market leadership.

Take the Next Step

We understand that every production requirement is unique. To provide you with the most relevant information, please select the option that best suits your current needs:

For immediate access to all technical data for your internal evaluation.

For a detailed discussion about customization, integration, and how this line can be tailored to your specific production goals.

For decision-makers ready to receive a detailed, personalized price proposal based on your required capacity and configurations.

Frequently Asked Questions (FAQ)

-

What is the price range for this complete production line?

As our lines are modular and configured to each client’s specific needs (capacity, heating type, product size), there is no fixed price. To provide an accurate quote, our engineers need a brief consultation to understand your production goals. Our aim is to provide the most cost-effective solution, not the most expensive one. Contact us to get a preliminary quote for your business.

-

What is the approximate Return on Investment (ROI) period?

ROI depends on your local labor costs, raw material costs, and product price. Our clients typically see a rapid return from: 1) Labor Cost Savings by reducing manual work to just 1-2 operators; 2) Increased Revenue from higher output (baseline 800 pcs/h); and 3) Reduced Waste via our scrap recycling system. Based on client feedback, the ROI period is often between 12 and 24 months.

-

Can the line be customized for our specific pita bread size and thickness?

Absolutely. Customization is one of our core strengths. We can create custom forming molds for any size and shape. The roller thickness is precisely adjustable from 1-6 mm to achieve your desired final product. We can also test your specific flour or recipe at our facility to ensure perfect compatibility.

-

What about the long-term reliability and key component brands?

Reliability is a primary design principle. All food-contact parts are 304 stainless steel. We use reputable, industry-standard brands for critical components like motors, bearings, and electrical systems to ensure stable, long-term operation. Our equipment’s durability has been proven in commercial environments in Turkey, the UAE, and other countries.

-

What after-sales support and warranty do you offer for international clients?

We provide a comprehensive global support system: a 12-month warranty, 24/7 remote technical support, a readily available stock of spare parts for fast international shipping, and the option for on-site engineer service for complex installation or maintenance needs.

-

How are installation and operator training handled?

We offer two flexible options. Remote Guided Installation, using detailed manuals and video support, is sufficient for most clients. For a seamless start, we recommend On-Site Installation, where our engineer travels to your facility to oversee installation, commissioning, and provide comprehensive hands-on training for your team.

-

Does the equipment comply with food safety and electrical standards in my country (e.g., USA, EU)?

Our equipment is built following international GMP (Good Manufacturing Practice) principles. We can configure the electrical systems and safety features to meet specific regional standards, such as CE for Europe or UL for the United States, to ensure your line passes local compliance inspections. Please inform us of your required standards during your consultation.