Mango Juice Pulp Production Line | Mango Pulp Juicer Machine

Industrial mango juice production line is an important project for large-scale processing of mango juice. Various kinds of mangoes can be used as raw materials for the mango juice processing plant. The complete mango pulp production line mainly includes mango washing, sorting, beating, pitting, preheating, refining, sterilizing, and mango juice filling. The mango pulp produced by the mango juice processing equipment can be sold directly to supermarkets, restaurants, fast food restaurants, retail stores, etc. The production capacity of mango juice production line is generally between 1 ton/day and 2500 tons/day. Our factory can customize the most cost-effective mango pulp processing line according to the actual needs of customers.

Why choose mango juice production business?

Most of the customers who choose the mango juice processing business said that the market sales of mango juice are very good. People generally like the sweet taste of mango juice. In fact, the main reason for the popularity of the mango juice processing business is the high nutritional value of mango juice and the high profitability of selling mango juice.

The nutritional value of mango juice

Mango juice is made by squeezing or mixing the juice from mango pulp. Each cup of mango juice contains a lot of vitamin C, vitamin A, potassium, iron, various carotenoids, and powerful organic acids. Mango has unique nutrients and limited nutrients. A serving of mango juice can provide you with more than 60% of ascorbic acid and more than 40% of vitamin A. Mango juice is also rich in calcium and iron, potassium, magnesium, various vitamin B, manganese, selenium, and copper.

Market sales of mango juice pulp

Mango juice is a high-concentration juice. Because of its mellow taste, its market acceptance is very high. This kind of fruit and vegetable juice beverage with high juice content is rich in mineral elements and other natural nutrients and contains no or less synthetic food additives.

Judging from the development trajectory of international fruit juice beverages, with the improvement of consumers’ living standards and changes in consumption concepts, pure natural fruit juice beverages will become an inevitable development direction. In addition, the production of high-concentration juices such as mango juice has the characteristics of high gross profit and large profit margins.

Processing details of the mango pulp processing line

Processing material: fresh mango

Mango juice yield: about 75% (25% in mango peel and core)

Specifications of finished mango juice: concentrated mango juice, concentrated mango jam, mango juice beverage, etc.

Common mango juice packaging forms: aseptic bag packaging/glass bottle packaging/PET bottle packaging

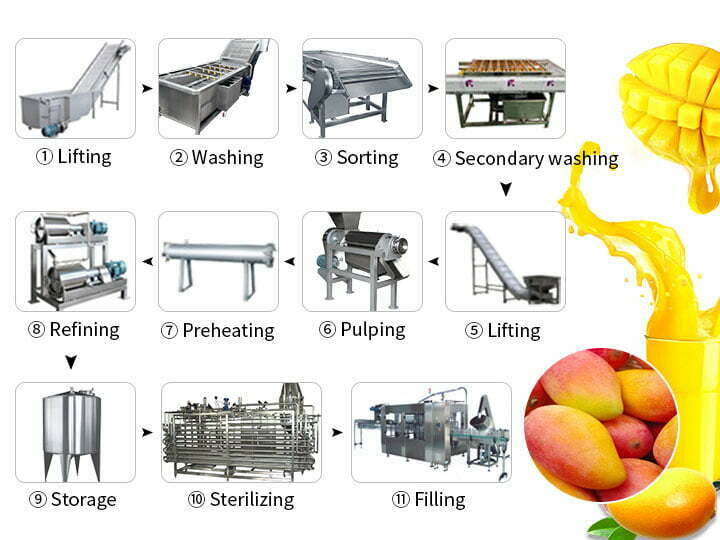

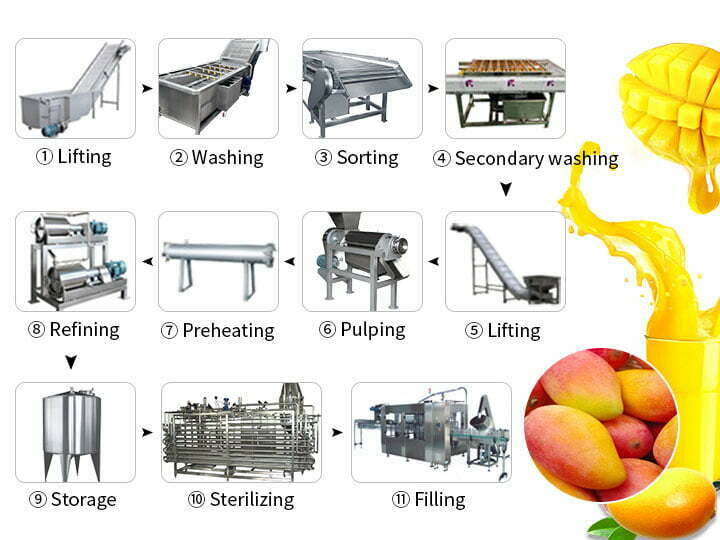

Workflow of mango juice pulp production line

The complete processing flow of the industrial mango juice production line mainly includes cleaning, sorting, secondary cleaning, de-core beating, preheating, refining, sterilization, and filling. In the fully automatic mango pulp processing line, we usually need to use elevators instead of manual labor. The concentration of mango juice produced by this mango juice processing plant is about 65-72 Brix.

The mango juice production line avoids the traditional shortcomings of low juice processing output and immature technology in the past. The processing method designed by our factory to produce high-quality mango juice concentrate is to select mango varieties and improve the processing technology to increase the mango juice yield and product concentration to obtain high-quality mango juice concentrate.

Step 1 Fresh mango lifting

To make high-quality mango juice, we can choose more suitable mango varieties to ensure higher mango juice yield and mango juice concentration. Put the mangoes in the funnel of the automatic elevator, and the mangoes will be gradually raised to the cleaning equipment, which can save a lot of labor.

Step 2 Mango washing

The mango cleaning machine in the mango juice processing line is a bubble washing machine. This high-efficiency air-wave cleaning machine can quickly remove sand, soil, hair, and other spoilage impurities on the surface of mangoes. The large number of bubbles produced by the washing machine can make the mango tumbling continuously during the washing process so that it can be completely washed.

Step 3 Mango sorting

In the mango pulp production line, mango sorting is a very necessary link. We can pick out spoiled mangoes and small immature mangoes, which can reduce the impact on the taste of mango juice. The automatic fruit picking machine uses the principle of screw rolling to automatically sort out smaller mangoes.

Step 4 Secondary washing

The reason why the mangoes are washed twice before the mangoes are beaten is to ensure cleanliness of the mangoes. Mangoes may be contaminated with impurities during the sorting process, so a second spray cleaning is required. This type of hair roller washing machine not only has a cleaning function, but its brush structure can also remove impurities such as hair that are not easily found in the mango.

Step 5 Mango pulping (juicing)

We use a double-channel fruit beater to squeeze the cleaned mangoes. This electric mango pulp juicer machine can ensure the maximum juice yield of mangoes, and can quickly remove mango cores and mango skins. In this mango juice extraction process, the utilization rate of mangoes can be maintained at more than 80%.

Step 6 Preheating & enzyme-killing

After the mango pulp is prepared, it needs to be preheated and enzyme-inactivated immediately. The purpose is to reduce the cell activity of the mango juice, maintain the original color of the mango juice and obtain a more mellow and uniform mango juice.

We use this sleeve-type preheater to preheat mango juice to kill enzymes. Before preheating, we can add citric acid to the mango juice to adjust the pH of the mango pulp to between 3.5 and 4.0. The preheater can complete enzyme inactivation and cooling within 3 minutes. The preheating process can kill the polyphenol oxidase and other phenolases in the mango juice to prevent browning during the subsequent adding process. Enzyme inactivation temperature is 65~80℃. The temperature after cooling is 45-60°C.

Step 7 Mango pulp refining

In the refining process of mango juice, mango juice of different concentrations can be processed according to customer needs. The inactivated mango slurry is cooled to below 40°C and centrifuged to separate the mango juice and the puree. Mango juice can also be vacuum concentrated to about 65-70°Brix, and sterilized and filled to obtain concentrated mango juice.

The concentrated juice can also be mixed with the fruit puree separated by the centrifuge, and then sterilized and filled to obtain a mango concentrated juice with high pulp content, the concentration of which is between 45-60°Brix.

Step 8 Mango juice sterilizing

In order to ensure food health, any drinks and juices produced by food factories need to be sterilized. In the mango juice production line, we mainly use tube-and-tube sterilizers to quickly sterilize mango juice. For small mango juice processing plants, the mango juice can also be processed by filling first and then sterilizing.

The casing type sterilizer is mainly composed of a continuous pipeline structure, and the mango juice will be quickly sterilized by the high temperature steam added by the pipeline during the flow of the pipeline. This high-temperature instant sterilization can ensure that the nutrients of the material are not damaged, not lost, and will not change the color of the mango juice.

Step 9 Mango juice filling

Mango juice filling is the last link in the mango juice production line. For mango juice filling, we usually use a fully automatic aseptic filling line, which can realize various packaging of mango juice, such as aseptic bags, glass bottles, and PET bottles. And in the mango juice filling process, the functions of automatic blowing, filling, labeling or sleeve labeling, coding and film coating can be realized.