Flour Tortilla Making Machine | Vegetable Chapati Roll & Pita Bread Machine

The automatic flour tortilla making machine is the food processing equipment for processing various cooked wraps, such as vegetable Chapati rolls, Arabic pita bread, soft flatbread, tortilla wraps, etc. The conveyor belt of the commercial tortilla wraps maker machine The dough (or batter) can be sent to the bottom of the forming mold of the machine. The forming mold can squeeze the dough into a pie-shaped cake for heating and baking, and the baked wraps are output by the conveyor belt for cooling.

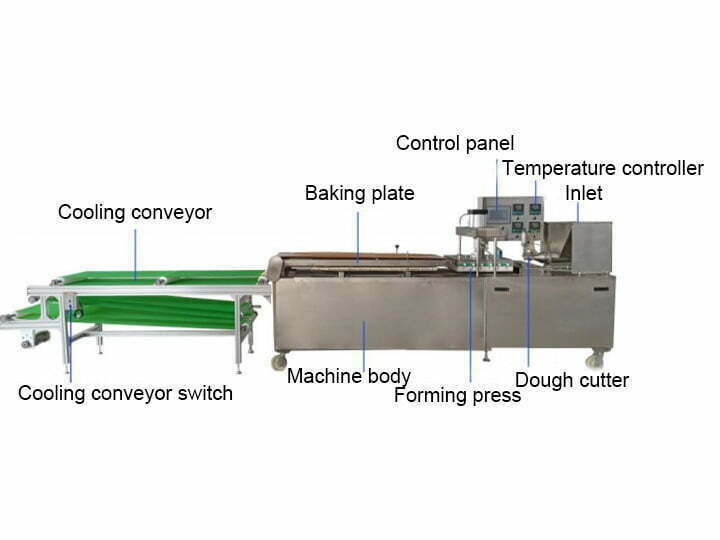

Commercial flour tortilla making machine structure & working process

The structure of the flour tortilla wraps maker machine is specially designed, with a beautiful appearance, compact structure, convenient use, and easy maintenance. The soft chapati roll machine mainly includes a dough-cutting device, dough extrusion system, baking system, automatic conveying, and cooling system.

- Dough feeding and cutting. The inlet of the flour tortilla making machine is a trough structure with a spiral inside. When the dough is put into the inlet, its internal spiral will squeeze and push the dough forward. When the dough is extruded from the front, the automatic cutter at the exit will cut the dough into small pieces of the same length.

- Dough sheets pressing. The dough sheet press system of this tortilla rolls making machine can quickly extrude the cut dough into a round shape. The thickness of the pressed dough sheets is uniform and the surface is flat. The pressure of the press device can be adjusted.

vegetable chapati rolls maker structural features - Tortilla wraps baking. The pressed dough sheets will be transported forward and enter the baking system. The baking system of this flour tortilla making machine is a set of horizontal baking trays. When the conveyor conveys the dough sheets between the two baking trays, they will be evenly heated until cooked. Then it is conveyed forward by the conveyor.

- Soft Chapati pita bread cooking. The processed tortilla wraps will be conveyed by the conveyor to the cooling device for rapid cooling. The cooled tortilla wraps can be eaten and sold directly, or they can be packed into individual bags using a packaging machine.

Main features of the flour tortilla wrap maker machine

- The vegetable chapati rolls machine can process cooked noodles of various sizes. The diameter of tortilla wraps can be adjusted between 5cm-350cm, and the thickness can be adjusted between 0.3mm-2mm. We can also customize the cooked flatbread required by customers according to their processing needs

wraps size.

cooked Mexican tortilla wraps - In addition to processing ordinary pita sheets, this flour tortilla making machine can also make a variety of vegetable rolls in different colors. We only need to add vegetable juices and juices of different colors in the wraps-making process, such as spinach juice, celery juice, pumpkin juice, purple potato juice, etc. This vegetable wrap is not only brighter in color, but also more nutritious and healthy.

- If customers want to produce fully automatic flour tortilla wrap rolls, we can also help complete tortilla wraps and chapati rolls production lines. Of course, we can also recommend suitable dough mixers and automatic packaging machines for customers.

- Many customers want to know whether this machine can make spring roll wrappers, and the answer is no. We have a special spring roll machine to make spring rolls.

Technical parameters of the tortilla chapati wrap making machine

| Model | TZ-L350 | TZ-L450 |

| Power | 5kw | 22kw |

| Voltage | 380v, 50Hz/ Customized | 380v, 50Hz/ Customized |

| Capacity | 200-360pcs/h | 700pcs/h |

| Lavash diameter | 100-400mm | 80-400mm |

| Thickness | 0.3-2mm | 0.3-2mm |

| Working temperature | 150-280℃ | 150-280℃ |

| Over Size | 3500*800*1400mm | 4850*800*1450mm |

| Packing weight | 100kg | 650kg |

Usage of the vegetable Chapati rolls machine’s mold

1. The surface of the new mold of the flour tortilla making machine generally has a layer of protective oil, which is an industrial oil. Therefore, before using it for the first time, it should be boiled in boiling water and then rinsed with detergent before use.

2. Regardless of the mold, it is recommended to apply a thin layer of cream before baking, and then sprinkle some high-gluten flour, or spread the mold with anti-sticking paper, so that the baked wraps will not stick.

3. When using a stamper to make flour tortilla wraps or pita bread, put the stamper on the flour first, and then press the dough. The pressed dough can be easily removed.

6. After the mold of Tortilla wrap maker is used up, it should be cleaned, and the water stain should be dried or wiped dry to prevent rust.