Spring Roll Sheet Machine | Pancake Maker | Spring Roll Machine

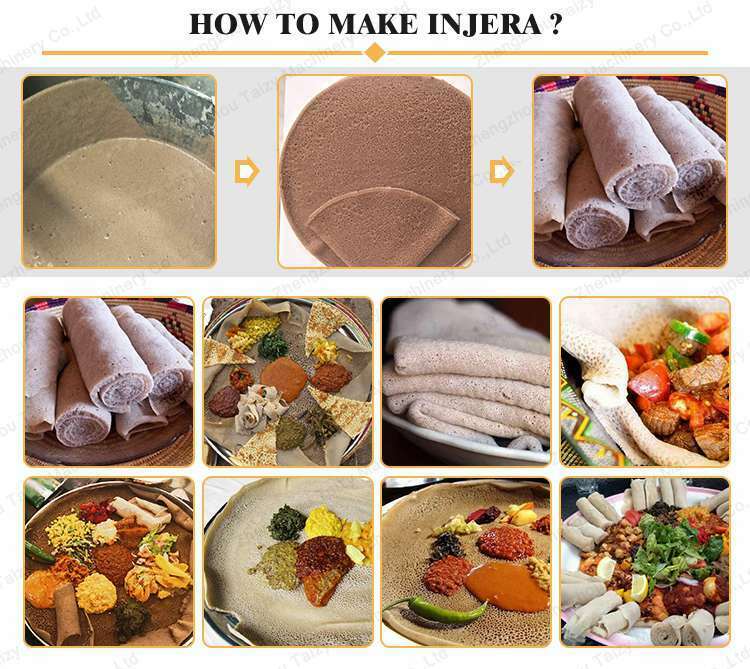

Spring Roll Sheet Machine is a food equipment used to make spring roll sheets on a large scale. Our machine can make up to 5000-6000 spring roll sheets in one hour. This spring roll sheet maker is also named pancake machine, chapatti making machine, injera maker machine, and so on.

Spring rolls production line video

Taizy Food Machinery is the spring roll sheet machine manufacturer and supplier so we can provide good spring roll processing equipment for commercial production of spring roll sheets. This automatic machine mainly can make the spring roll sheets with round and square shapes of different specifications, besides, the yield and the spring roll wrapper’s size of this machine can be customized according to customer needs.

What is the spring roll sheet machine?

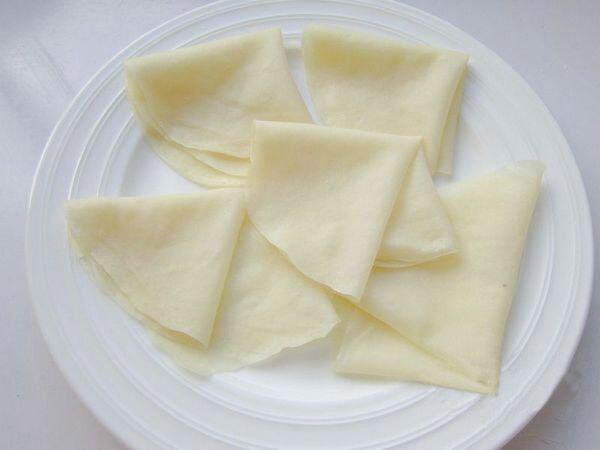

The high-quality spring roll sheet machine is mainly to make the cooked spring roll sheets on a large scale. It is the ideal equipment for processing spring rolls for sale. The spring roll sheets made by this machine can be round and square shapes with different diameters and the thickness of the spring roll sheets range from 0.3mm to 1.2mm. The spring roll machine has the advantages of high work efficiency and a safe and hygienic production process.

How to make spring roll wrappers automatically?

The automatic spring roll sheet machines are the new-designed kitchen equipment that uses well-mixed water and flour to make pie-shaped cooked food. It consists mainly of a frame, pneumatic components, electrical components, heating elements, and forming dies. The spring roll sheet machine is mainly used for making spring rolls, samosa wrapping sheets, egg cakes, roast duck burritos, dumpling wrappers, rice pastry sheets, French crepes, and other kinds of wrapping sheets for vegetables and meats.

The heating methods can be electric heating, gas heating, electromagnetic heating, and resistance wire heating. This spring roll forming machine can match an automatic folding and counting device and a packaging machine when used in the spring roll sheets production line.

Do you need a high-quality spring roll sheet maker to help you improve your productivity? Welcome to contact us for more information about this machine.

How does the spring roll sheet machine work?

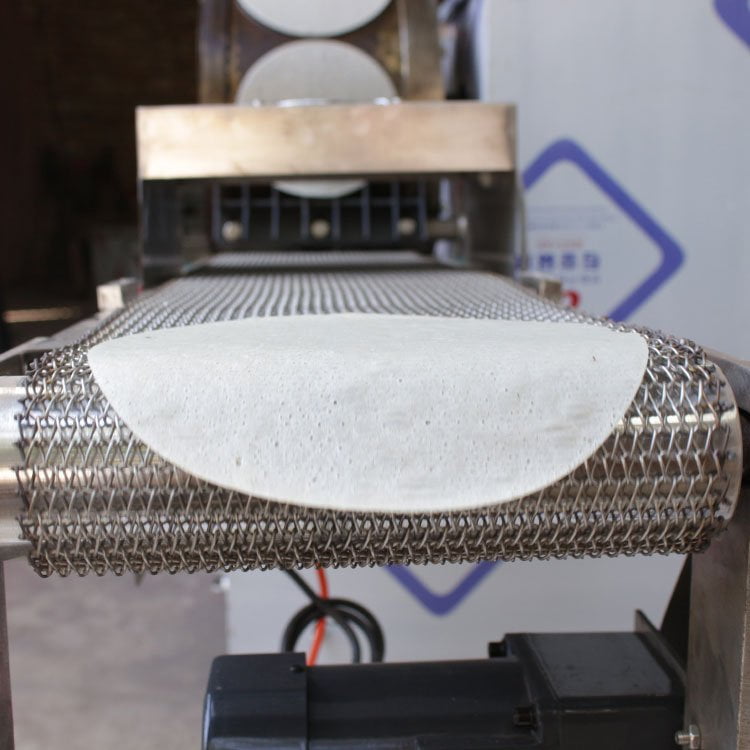

When using the spring roll machine, first, put the prepared flour pastry into the discharging bucket. Heat the rotating roasting wheel and bring its temperature to around 160 ℃. The slurry pump is then turned on and the slurry is sent from the delivery tube to the slurry nozzle.

The nozzle will evenly spread the pulp on the mold on the arc surface of the baking wheel. Subsequently, the pulp on the mold naturally matures when the high-temperature rotating roasting wheel is rotated at an angle of 270-300 degrees. Then, the final cooked spring roll product is automatically separated from the roasting wheel to form a spring roll of a fixed thickness, which is then dropped onto the conveyor belt and conveyed and cooled.

How to prepare the flour pulp for making spring roll sheets?

Add water to the pulp beater barrel(water temperature around 30 °C), then add cooking oil, and finally add flour. The mixing ratio is flour 50 kg, water 67.5-77.5 kg, edible oil 300-400g, and salt 250-400g. The raw materials available are flour, pastry powder (low gluten), and common flour (high gluten). When beating, 10% of corn starch can be added to make the spring roll sheet shiny. When the beating starts, stir it for 5 minutes. Then stop for 10 minutes. Then, stir for another 5 minutes, stop for another 10 minutes, and repeat three times to use.

The main advantages of the spring roll sheet maker

- The working process of the spring roll machine is no loud noise and this machine is very compact in structure and has a long service life. Our company can not only manufacture and trade high-quality machines at a good price but also can offer you the best services about the spring roll sheets production solutions and other details.

- The final spring roll skin made by the spring roll sheet machine has regular shapes and sizes with even thickness. The spring roll size can be customized based on customer requirements.

- This spring roll sheet machine has stable performance and a unique mechanism, which can save labor and time costs. One person can operate, and no technical experience can start the spring roll production.

- The spring rolls processing machine has simple operation, a high degree of automation, and various heating methods. Both two-phase and three-phase power supplies are available for electrical heating.

- The spring roll sheet machine can match with the automatic folding and counting device for the production of spring roll sheets on a large scale. With high efficiency, this commercial food processing equipment has been shipped to many foreign countries like Singapore, India, and Turkey, and even some Vietnamese have been our long-term partners.

- The ratio of water to flour in the pulp is 1 kg of flour: 1.2 kg of water; when the water in the flour pulp is less, the spring rolls are slightly thicker; when the water in the pulp is more, the spring rolls are made thinner. Therefore, the thickness of the spring roll sheets can be achieved by adjusting the proportion of the dough.

How to install and use the chapatti pancake maker?

To prolong the service life of the spring roll machine, you need to install and use the machine according to the following points.

- When working, the machine should be placed on a level surface.

- When installing the machine, the heating cylinder must be parallel to the axis and the machine should be stable.

- Turn on the power and turn on the buttons labeled L1, L2, L3, and N in the box door. L1, L2, and L3 are three firewire terminals, respectively, and N is a zero line.

- Add a small amount of cooking oil to the surface of the heating cylinder before using the machine.

- Before the machine is used, the ground wire must be connected, and the 2.5 m long galvanized iron needle welding screw is connected with the 6 m2 copper wire. Connect the copper wire to the spring roll sheet machine casing and insert the iron pin into the ground.

- After the end of production, the pulp bucket, slurry pump, and mold must be cleaned with clean water. The main switch must be switched off during machine maintenance.

Technical parameters of the Ethiopian injera maker machine

| Parameter | TZ-3620 | TZ-5029 | TZ-8045 | TZ-112060 |

| Power(KW) | 1.2 | 1.2 | 1.0 | 1.0 |

| Voltage(v) | 220/380 | 380 | 380 | 380 |

| Heating power(KW) | 6 | 13 | 32 | 40 |

| Output (piece/h) | 800-1000 | 1500-2000 | 3000-4000 | 5000-6000 |

| Dimension(mm) | 4500*660*890 | 4900*800*1350 | 2600*1100*1600 | 3000*1300*1800 |

| Revolving speed(r/min) | 1-2.5 | 1-2.5 | 2-3 | 2-3 |

| Weight(kg) | 260 | 520 | 700 | 850 |

| Heating barrel size(mm) | 400*280 | 500*330 | 800*600 | 1200*600 |

| Mold size(mm) | 60-200 | 60-290 | 450 | 600 |

The four commercial spring roll makers have different outputs, dimensions, weights, and mold sizes. The output is 800-1000 piece/h, 1500-2000 piece/h, 3000-4000 piece/h and 5000-6000 piece/h respectively. The choice of a spring roll sheet machine depends on your output requirements. If you have other requirements, please feel free to contact us.

FAQ

Can the thickness of the spring roll sheets be adjusted?

Yes, the thickness of the spring roll sheets can be adjusted and set according to the customer’s requirements before the machine is shipped.

Can I make both round and square shape of spring roll sheets in this one machine?

Yes, of course. We can provide different molds for making the spring roll sheets with various shapes and sizes. You can change it easily by yourself when you making the spring roll sheets.

What is the heating method for the pancake maker machine?

Usually, we can use both electricity and liquefied gas as the main heating resource for making the pancake and spring roll wrappers.

How to make spring rolls?

spring roll recipes are various and different in many places. The first step to making spring roll is to make the spring roll sheets. And the spring roll sheet maker can be a good helper.

What are the spring roll recipes?

For starting a new business, we can provide you with both the spring roll sheet making machine and the spring roll recipes for doing commercial spring roll production.