Tomato & Strawberry Washing and Drying Line Machine

The industrial tomato and strawberry washing and drying line is mainly used for cleaning and air-drying bulbous vegetables and fruits with smooth surfaces. This continuous vegetable washing line mainly includes automatic conveyor (or elevator), bubble washing machine, impurity removing machine, air dryer and manual picking table. The tomato washing and drying line is often used in various large canteens, clean vegetable distribution centers and food processing plants, which can replace a large amount of manual labor, reduce labor intensity, save labor costs, and improve vegetable cleaning efficiency.

Why is the fruit and vegetable washing line so popular now?

Nowadays, fruit and vegetable washing lines of various scales are widely used in many food processing industries. Why? There are two main reasons: First, the automatic fruit and vegetable washing line can replace the labor of workers and save costs. Nowadays, the price of workers is getting more and more expensive, and the use of fruit and vegetable washing lines can reduce labor input and labor costs.

Second, the fruit and vegetable washing line has high working efficiency and large output. With the industrialized production of food, there is an increasing demand for fruit and vegetable cleaning, and manual cleaning is time-consuming and laborious, so the use of fruit and vegetable cleaning equipment can improve efficiency.

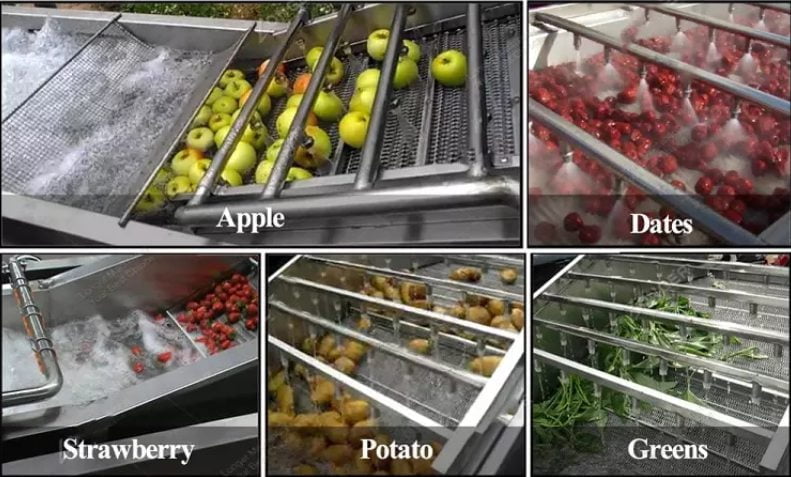

What can be washed with the tomato & strawberry washing and drying line?

The tomato and strawberry washing and drying line has a wide range of uses, mainly for cleaning all kinds of vegetables and fruits, such as apples, pears, strawberries, tomatoes, peaches, eggplants, peppers, avocados, mushrooms, broccoli, etc.

Main components of tomato & strawberry washing and drying line

The configuration schemes of fruit and vegetable washing lines provided by different factories are different, and their processing capacity is also different. However, the basic principles of modern fruit and vegetable cleaning equipment are the same. The tomato and strawberry washing and drying lines designed by our factory and exported abroad mainly include automatic elevators, bubble washers, impurity removers, air dryers and manual picking stations.

Automatic hoist conveyor

This hosit conveyor has the main function of automatic elevating of raw materials. It is mainly driven by the motor power and it’s transporting speed can be adjusted. Besides, the length and height of the automatic hoist elevator can be customized according to the user’s production needs.

Bubble washing machine

The bubble washer is the main equipment of the washing line. The machine has a turbocharger, which can generate a large amount of airflow. When the airflow blows to the water in the cleaning tank, a large amount of air bubbles will be generated for cleaning the material. The water used for cleaning materials can be recycled through the filter device to quickly remove sediment and other impurities.

Impurity removing machine

The impurity remover is usually placed behind the bubble cleaning machine, and is mainly used to further remove impurities such as hair and debris on the surface of fruits and vegetables. After some materials are cleaned by a bubble cleaning machine, the hair and debris on the surface cannot be removed, so further cleaning of the equipment is required. This machine has multiple sets of hair rollers. When in motion, the rotating brush can brush down the hair that is difficult to remove on the surface of the material.

Air-drying machine

After tomatoes and strawberries are cleaned, there are often many large water droplets on their surface, so they cannot be directly packaged and transported. You can use this air dryer for quick air drying. The continuous air dryer has multiple sets of fans, and the number of fans can be customized, and the height of the fans can be adjusted manually.

Labor picking table

The selection station is optional, depending on whether the user needs it. Workers can pick out bad tomatoes or strawberries on both sides of the picking table, or classify them according to the size of the materials.

Tomato & strawberry washing line’s features

1. The automatic fruit and vegetable cleaning line has a high degree of automation, which can replace workers to clean materials, reduce labor intensity and save labor costs.

2.The processing efficiency of the strawberry washing line is very high, and its processing capacity per hour is between 50kg and 1000kg. We can also customize the washing line according to customer needs.

3. If customers need, we can also add corresponding fruit and vegetable slicers, frying machines and packaging machines to the fruit and vegetable washing line.