Frozen Meat Slicer | Slicing Machine Manufacturer

The commercial frozen meat slicer also called the meat slicing machine and frozen meat slicer, is a very efficient equipment for making meat slices and meat rolls. This kind of meat cutting equipment mainly cuts frozen meat into thin rolls or flakes, usually mutton rolls, chicken rolls, beef rolls, bacon, and so on.

Working video of the mutton rolls slicer machine

We all know that meat slices like mutton or beef rolls and bacon are the common meat products for having a good meal, especially for eating hot pot or barbecue. This frozen meat slicer can make the meat rolls with good shapes and even thickness, and the meat rolls’ thickness can be adjusted manually. In addition, we also have the meat cutting machine for sale.

Automatic frozen meat slicer machine description

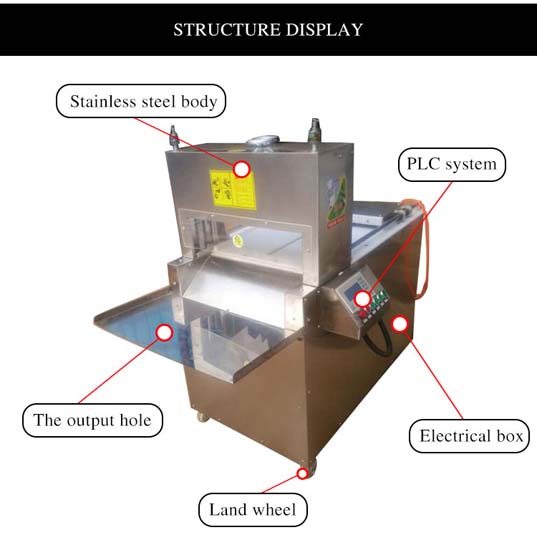

The CNC lamb cutting machine adopts PLC control, which completely solves the problem of the high failure rate of the mechanical slicer. Moreover, it has an infrared-inductive safety protection device, which is very safe to operate, and truly realizes the full automation of meat roll production.

When adjusting the thickness of the slice, it does not need to stop and can be directly adjusted in the numerical control switch according to the required thickness.

The mutton meat slicer machine can cut 2-8 rolls of mutton or beef at a time and can cut 50-400 kg per hour. The machine’s workbench is made of food-specific organic plastic plates, which can ensure food safety and hygiene. It is the first choice for large-scale hot pot restaurants and large and medium-sized beef and mutton wholesalers.

Main classifications of the frozen meat slicing machine

Electric single–roll frozen meat slicer

Technical parameters

| Power | Voltage | Cutting speed | Output | Slice thickness | Weight | Dimension |

| 0.45kw | 220v | 50-60pieces/h | 25-50kg/h | 0.2-5mm | 50kg | 650*350*400mm |

The output of this small frozen meat slicer is 25-50kg/h. If you have clothes in a small restaurant, then you can choose this machine.

CNC two-roll meat slicing machine

Technical parameters

| Power | Voltage | Cutting speed | Output | Slice thickness | Weight | Dimension |

| 1.5kw | 220v/380v | 50-60pieces/h | 100-150kg/h | 0.2-20mm | 200kg | 1100*450*1200mm |

The output of double roll meat slicer is 100-150kg/h. The thickness of meat slices can be adjusted between 0.2-20mm.

CNC four-roll frozen meat slicers maker

Technical parameters

| Power | Voltage | Cutting speed | Output | Slice thickness | Weight | Dimension |

| 1.5kw-3.5kw | 220v/380v | 50-60pieces/h | 250-300kg/h | 0.2-20mm | 300kg | 1450*660*1300mm |

Do you need an 8 roll frozen meat slicing machine to help you increase the efficiency of slicing lamb rolls? If so, please contact us as soon as possible.

CNC eight-rolls frozen meat slicer machine

Technical parameters

| Power | Voltage | Cutting speed | Output | Slice thickness | Weight | Dimension |

| 3.5kw | 380v | 50-60pieces/h | 450-500kg/h | 0.2-20mm | 400kg | 1450*1010*1450mm |

Frozen meat slicing machine’s main features

- This meat slicer machine can cut frozen meat into slices or rolls with different thicknesses quickly, which is easy to operate and maintain.

- Its intelligent CNC panel uses a combination of buttons and knobs to ensure easy operation and safety.

- The machine’s unique feed pusher system allows the material to advance evenly and the slice thickness is uniform.

- This meat slicing machine adopts high-quality electrical accessories and has good safety protection performance. Stainless steel case, clean and easy to wipe, seamless welding, solid body, and long service life.

- This frozen meat slicer machine can be different models, we can also customize the machine according to customers’ requirements.

- The frozen meat block does not need to be thawed, can be directly operated on the machine, and can cut out a variety of roll shapes (coarse roll, fine roll, long roll), the shape is neat and beautiful, easy to package with high processing efficiency, safety, and labor-saving.

Electric meat slicing machine operation and maintenance

- Observe the connection line before use, and must be connected to the ground wire. The machine can be used without any errors to prevent leakage.

- When using this meat slicer machine, start the motor first, then put the meat block for cutting.

- When cutting meat slices and meat rolls, the meat must be cleaned to prevent damage to the blade.

- When the meat slicing machine is not working, clean the stains, water stains, and other stains adhering to the product in time. Keeping the machine clean and replacing consumables can extend the life of the machine and make the product more hygienic.