Sponge Cake Depositor | Cupcake Batter Filling Machine

The commercial cake batter filling machine (cake depositor) is a new-designed cupcake batter dispensing equipment. This kind of cake making machine is especially suitable for the industrial production of cupcakes, cookies, sponge cakes, pancakes, etc. The cake grouting machine is mainly composed of an automatic grouting system and an automatic conveyor. The automatic cake paste injection machine can quantitatively inject the evenly mixed cake batter into the cake mold.

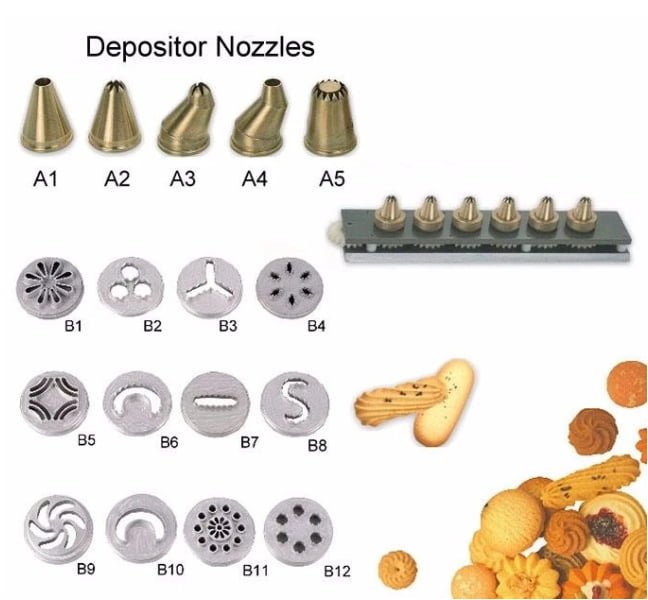

Moreover, we can replace different grouting nozzles and different baking tray molds to make cakes of various shapes and sizes. With the great advantages of large yield and automatic cake batter filling, this electric cake batter filling machine is widely used in all kinds of bakeries, fast-food restaurants, hotels, food processing plants, etc.

Labor cake filling VS Cake depositor filling

Cake batter filling is the common step for making delicious cupcakes and pancakes in many bakeries. Many small cake processing plants may employ laborers for squeezing the cake pastes into the cups or other molds with different shapes. But labor filling for cake filling is very inefficient and costly. However, the automatic cake filling machine can replace this work, which can fill the cake batter into the trays with various shapes very quickly. And the batter filling amount and filling speed is adjustable.

Applications of the commercial cake batter filling machine

The cupcake batter filling machine is widely used in large and medium-sized food production enterprises and pastry processing plants mainly used to process various French soft bread, cupcakes, European-style cakes, shell cakes, etc. According to the different requirements of the size and shape of the baking pan of the machine, it can be equipped with different specifications of the discharge nozzle, and various shapes of cake forming baking pan can be customized.

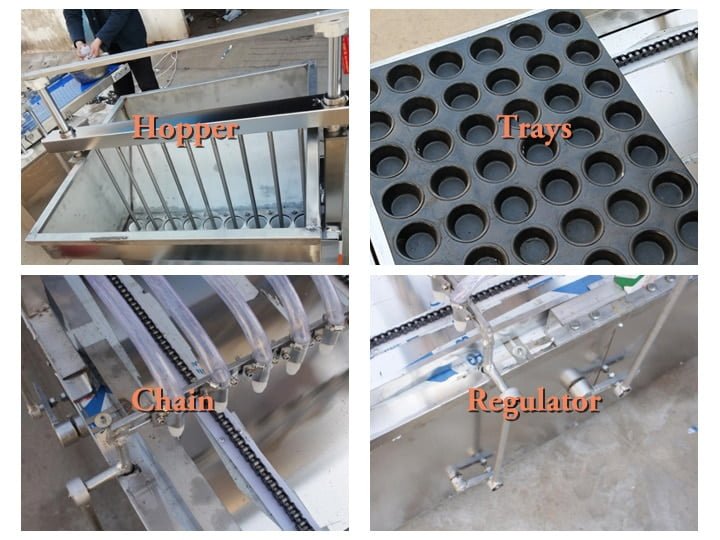

Structure of the automatic sponge cake depositor

The cake batter filler machine mainly includes the feed hopper, PLC touch screen, chain transmission structure, motor, air compressor device, cake batter filling nozzles, belt conveyor, trays, and the machine frame. All parts of this cake batter filling machine are made of stainless steel so that it is very durable for long time use. The mixing shafts of the machine feed hopper can stir the cake pastes continuously during the whole cake batter filling process.

The intelligent PLC controller can be set with different languages for easy operation. Besides, each filling amount of the cake batter can be set on this touch screen according to the customers’ requirements for making cupcakes. The belt conveyor’s transporting speed is also adjustable. The cake batter grouting machine is mainly used for grouting pneumatically, so an air compressor is required when using this cake batter filling machine.

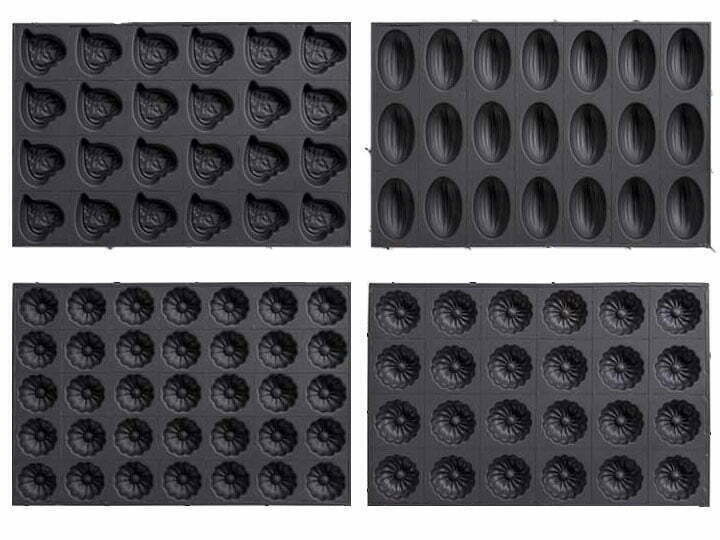

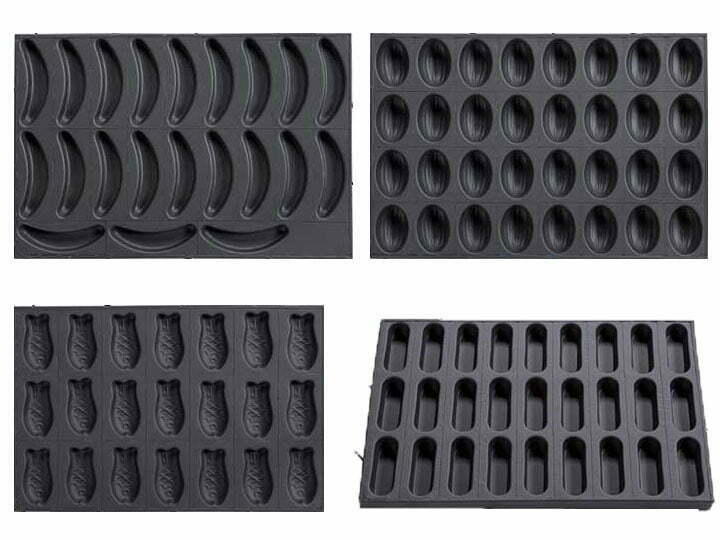

Replaceable sponge cake baking mold of the cake depositor machine

When using this cake depositor to make cupcakes, we can not only replace different batter nozzles but also process sponge cakes of different specifications by replacing the baking trays of different shapes. Common cake baking trays have heart-shaped and flower-shaped shapes. Shaped, round, oval, doughnut-shaped, and various animal patterns.

Usually, when our cake depositors leave the factory, Taizy food machinery will provide customers with two sets of baking molds for free. Of course, we can also customize the shape and size of the cake according to customer requirements.

How to make cupcakes with this cake batter filling machine?

As a cake depositor manufacturer and supplier with production and manufacturing capabilities, our factory continues to update and upgrade the machine, and currently has developed cake depositors with the function of automatically placing paper cups.

This cupcakes making machine adds a pneumatic device for continuously placing paper cups on the basis of the original cake filling machine. This pneumatic device can automatically put paper cups into the mold of the cake tray, instead of the tedious labor of manually placing paper cups, save time and effort, and can greatly improve the production efficiency of cupcakes. If you need, we can also provide you with an automatic cored cake maker machine, which can inject delicious fillings into the baked cakes.

Parameter of the industrial cake filling machine

| Model | TZ-F400 | TZ-F600 |

| Voltage(v) | 220 | 220 |

| Air pressure(Mpa) | 0.6 | 0.6 |

| Power(kw) | 1.5 | 1.65 |

| Length(mm) | 1700 | 1700 |

| Width(mm) | 820 | 1100 |

| Height(mm) | 1600 | 1600 |

| Capacity(kg/h) | 200 | 300 |

Cupcake filling machine advantages

- The cake pasting machine adopts computer programming with the features of compact structure, centralized function, and easy operation. It uses a cylinder as power and is equipped with photoelectric tracking, automatic quantitative extrusion, high accuracy, and accurate quantitative.

- The machine has a high degree of automation, low investment cost, easy equipment cleaning, and simple maintenance. It is widely used in various types of bread processing plants and food processing plants.

- The cake filling trays can be customized with different shapes or patterns. Besides, we can also provide the cake batter pulping machine and the commercial baking oven for roasting the cupcakes. And we can help you to design the whole cake production line.