Colloid mill for making peanut butter, nut butter

The Colloid mill also named a peanut butter machine is a kind of centrifugal emulsification equipment. It is extremely versatile and widely used in food, pharmaceutical, biological, chemical, and other fields. The equipment can handle high viscosity and large particle materials. Due to its high practicality, it is widely used in the food processing industry to process a variety of jams, peanut butter, sesame paste, and various dairy products.

Working video of the peanut butter machine

What is the colloid mill?

The colloid mill machine is a machine that can finely process materials. It combines a variety of properties of homogenizers, ball mills, shears, mixers, and other machinery, with superior ultrafine grinding, dispersion emulsification, homogenization, mixing, and other effects. After processing, the material has a particle size of 2 to 50 microns and a homogeneity of over 90%.

The colloid mill for peanut butter is the ideal equipment for ultrafine particle processing. This peanut processing machine is suitable for ultra-fine pulverization of wet materials in pharmaceutical, food, chemical, and other industries. It can pulverize, emulsify, homogenize, and mix various semi-wet bodies and emulsion materials.

How does the peanut butter making machine work?

When the nut butter machine is working, through the relative movement of the stator and rotor of different geometries under high-speed rotation, the material to be processed is subjected to strong shearing under the action of its weight, gas pressure, and centrifugal force through its internal annular variable gap.

The combination of force, friction, impact force, and high-frequency vibration, the materials are effectively dispersed, broken, emulsified, and mixed, to obtain the desired end product.

By the way, we need to roast the material to be processed beforehand using a nut roaster.

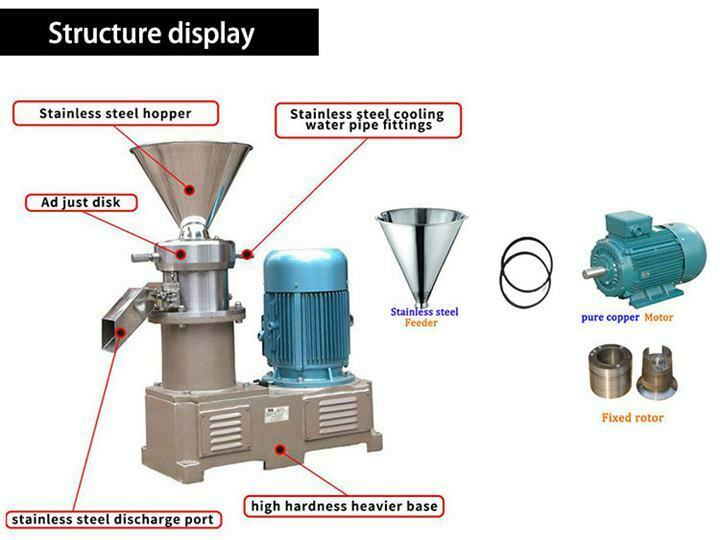

Peanut butter maker structural features

- This electric sesame paste making machine not only keeps the traditional colloid mill structure reasonable, easy to operate, convenient to maintain, small in size, and light in weight. It also has wide adaptability, simple shifting, and the ability to replace different types of motors for different processing objects.

- The crushing chamber of the sesame paste maker is provided with three grinding zones, one is a coarse grinding zone, the second is a fine grinding zone, and the third is an ultrafine grinding zone. By adjusting the gap between the stator and the rotor, the desired ultrafine pulverization effect can be effectively achieved.

Application ranges of the colloid mill

Colloid mills are widely used in the food industry, chemical industry, daily chemical industry, construction industry, and other industries to cut and mill materials.

- Food industry: aloe vera sauce, pineapple jam, sesame paste, ice cream, moon cake stuffing, cream, jam, juice, soy sauce, bean paste, peanut milk, protein milk, soy milk, dairy products, malted milk, flavors, various Beverage processing, etc.

- Chemical industry: paints, dyes, coatings, lubricants, greases, diesel, petroleum catalysts, emulsified asphalt, adhesives, detergents, etc.

- Daily chemistry: toothpaste, detergent, shampoo, shoe polish, cosmetics, bath essence, soap, balsam, etc.

- Pharmaceutical industry: various syrups, nutrient solutions, proprietary Chinese medicines, creamy agents, royal jelly, vaccines, various ointments, various oral liquids, injections, intravenous drip, emulsions, etc.

- Construction industry: various coatings: including interior and exterior wall coatings, anti-corrosion and waterproof coatings, cold porcelain coatings, colorful coatings, ceramic glazes, etc.

- Other industries: plastics industry, textile industry, paper industry, bio-chemicals, nano-materials, etc.

The main advantages of the peanut butter grinder

- The main parts of the sesame butter machine are made of stainless steel, which is corrosion-resistant and non-toxic. The internal tooth structure is small in size and low in energy consumption.

- The main working part of the machine is divided into stator and rotor, which are well-processed. The stator and rotor gap can be adjusted slightly by the positioning disc, and it is equipped with a dial for easy control and operation to ensure product quality.

- According to different processing purposes, we can choose different materials for the stator and rotor which are easy to disassemble. In addition, the machine speed can be adjusted, the user can order the appropriate machine model and the corresponding speed according to the specific material processing conditions.

Peanut butter machine use and maintenance

- Install the sesame paste maker horizontally on a flat concrete foundation and fix it with anchor screws (not fixed according to the working conditions).

- Check if the fastening screws are tightened (the rotor center screw is M12 left-hand screw).

- Before using the machine, use a special wrench to turn the rotor to check whether it is in contact with the stator and if there is any jam if it is not allowed to start the machine.

- Check and connect the power cable (three-phase AC, voltage 380 volts, body protection ground wire) and note that the direction of rotation of the rotor should be the same as the arrow on the base (clockwise rotation).

- When starting the motor, first turn on the switch to check if the peanut butter machine has noise and abnormal vibration. If the situation is not normal, stop it immediately, and then try again after troubleshooting.

- After the work is finished, the residual materials in the stator and rotor should be cleaned. The positioning disk is rotated counterclockwise by not less than 90° and then cleaned.

- One or more grindings may be performed according to material processing requirements. Several tests shall be performed before grinding to ensure optimum clearance and flow between the stator and rotor in the machine.

- When using the machine, pay attention to observing the grinding condition and running time of the machine. If there is any abnormal situation, stop it immediately and have a careful check.

Technical parameters of the peanut butter machine

| Model | TZ-50 | TZ-85 | TZ-130 | TZ-210 |

| The fineness of object processing(um) | 2-70 | 2-70 | 2-70 | 2-70 |

| Motor power(kw) | 1.5 | 5.5 7.5 | 7.5 11 | 30 |

| Output (self-inflow) r/min | 0.2-0.8 | 0.2-4 | 0.2-6 | 2-6 |

| No-load speed(cm) | 3000±100 | 3000±100 | 3000±100 | 3000±100 |

| Size(cm) | 50*23*70 | 105*30*84 | 127*38.5*102.5 | 120*50*130 |

| Weight(kg) | 60 | 185 | 240 | 600 |

| Remarks | Equipped with a cooling system | Equipped with a cooling system | Equipped with a cooling system | Equipped with a cooling system |

We have four models of colloid mills for sale. the fineness of object processing is 2-70um. If you are looking for an efficient colloid mill, please contact us.