Peanut Butter Production Line | Peanut Butter Making Machine

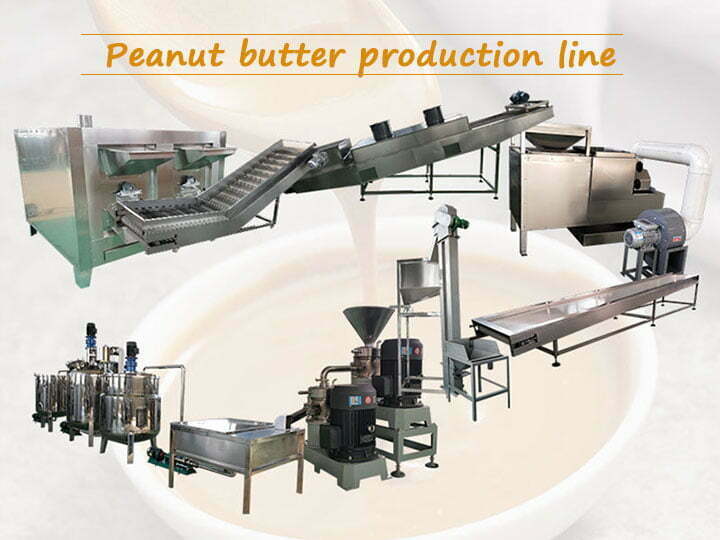

The peanut butter production line is a special processing line for making peanut butter. Our company has been specializing in making and trading high-quality peanut butter production lines for years, which are universally applied in small-scale industrial and commercial peanut butter making. Peanut butter is made by roasting, peeling, and grinding. And it can realize large-scale production. In addition, the entire production line can be designed as a semi-automatic or fully automatic production line. It is a table product with high nutritional value.

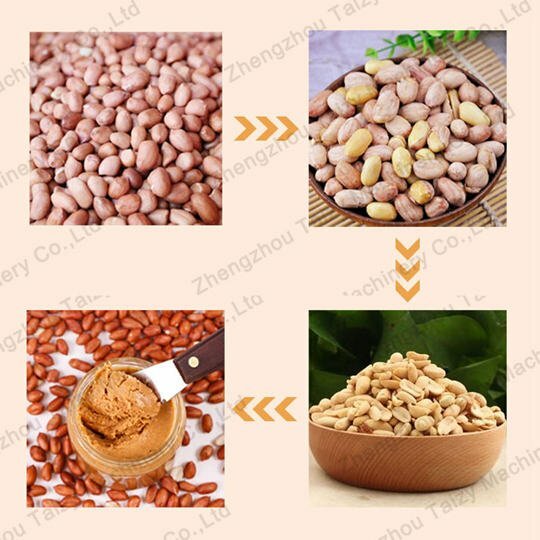

The processing production of peanut butter

Roasting: The peanuts must be roasted first. Because the roasted peanuts have a strong fragrance. Therefore you need to use a peanut roaster to help you achieve this function. This can make the peanut butter taste delicious. After that, the peanuts need to be cooled after roasting to be able to proceed to the next step. Because the freshly roasted peanuts are too hot.

Peeling: We all know that peanuts have red skin. If not handled will directly affect the taste of peanut butter. Taizy peanut peeler can make the roasted and cooled peanuts peeled and cut in half. In addition, some of the granular germs will also be screened out to ensure the quality of the peanut butter.

Grinding: Grinding can really turn peanuts into peanut butter. The peeled peanuts are ground into a paste by multiple peanut butter colloid mills, and then enter the mixing tank and the vacuum tank in sequence, and then can be filled to obtain the whole bottle of peanut butter.

Mixing: In order to make the peanut butter taste more unique, many peanut butter manufacturers add salt, sugar, and other seasonings. In addition, in order to make the flavor more uniform, we need mixing jars so that they can be mixed together evenly.

Degassing: The vacuum degassing tank can effectively remove the gas from the peanut butter. This can effectively extend the storage time of peanut butter.

Packaging: Finally, we need to use the packing machine to pack the peanut butter into finished products and then sell them.

From the process of making peanut butter, we can know that the peanut butter production line mainly includes roasting, cooling, peeling, grinding, mixing, degassing, and packaging. And the most important steps include baking, half-grain peeling, and grinding.

Parameter of the 500kg/h peanut butter production line

| 500kg peanut butter production line | Dimension | Weight | Power | Capacity(kg/h) |

| Peanut roasting&cooling machine | 8500*1800*2600mm | 2000kg | 130kw | 500kg/h |

| Peanut peeling machine | 1900*800*1350mm | 500kg | 3kw | 500kg/h |

| Combined colloid mill | 1400*1250*2000mm | 650kg | 30x2kw | 500kg/h |

| Vacuum&mixing&storage tank | 1500*250*250mm | 200kg | 1.5kw | 50kg/h*3 |

| Filling machine | 400*400*1400mm | 1000kg | 1.1kw | 100-400cans/h |

These are the machine parameters of the peanut butter processing line. With this processing line, you can get 500 kg of peanut butter in one hour. If you have other output requirements, please feel free to contact us.

Small scale peanut butter production line

If you have a limited budget and want to have a small peanut butter production line, we can provide you with customized services.

- We all know that the larger the output of peanut butter, the higher the price of the peanut butter making machine. We can choose a small-scale production line for you, such as a 200kg/h peanut butter processing line.

- Secondly, you can choose only a peanut roaster, peanut peeler, and peanut butter grinding machine. With only these three machines you can also easily start your peanut butter production business.

What you should know about building a peanut butter processing plant?

- Before investing, the first thing is to do market research. Determine the market position according to the input and output. For example, you need to consider how much peanuts are produced locally each year.

- Open up sales channels and identify target customers. Do a good job of adequate market research in order to lay a good foundation for the establishment of peanut butter plants.

- Start building the factory. You need to make a plant plan according to the principles of plant design. And on this basis, you should make material accounting, consumables calculation, peanut butter machine selection, and water, electricity and steam consumption calculations.

- When building a factory, it is necessary to fully consider the development status and development trend of peanut butter. Then choose peanut butter processing equipment from the perspective of energy saving.

Advantages of the peanut butter production line

- According to the market demand, the peanut butter has been enhanced and optimized, so the peanut butter fineness has been will be further raised.

- It has the advantage of simple operation, stable operation, lower noise, easy maintenance, corrosion resistance, wide application, good reliability and so on.

- This production line is popular in the markets of various countries.

- Moreover, this peanut butter production line is not only suitable for peanuts, but also for sesame seed, rapeseed and other materials.