Commercial Food Coating Machine | Candy Peanut Chocolate Coater

The food coating machine is a very practical equipment for use in the food processing industry and pharmaceutical processing aspects. This sugar coater machine can coat all kinds of candies, chocolates, and pills with colorful sugar or seasoning flour, and polish to make the product smooth and beautiful.

Why the food coating machine is so popular now?

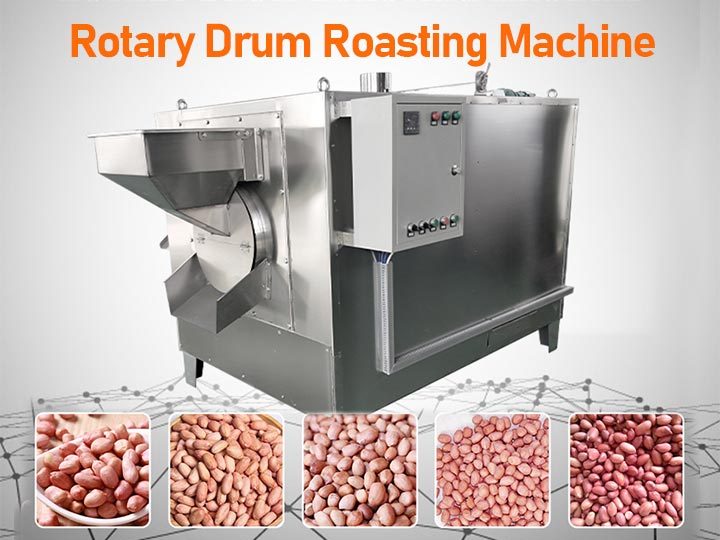

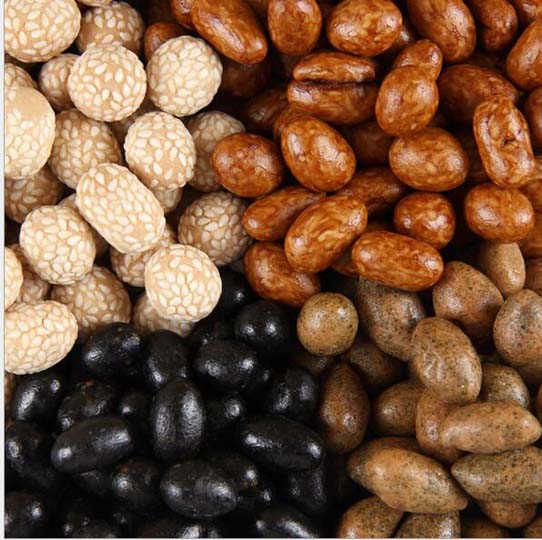

This automatic food coating machine is commonly used in candy and snack food processing fields as well as the pharmaceutical manufacturing industry. Especially, with the snack food processing development with new fashion, coated food, such as coated peanuts with different flavors, coated chocolates and candies are very popular among the people of all ages. Besides, this electric food coating machine can also be used for pills coating in many medicines making aspects. This kind of electric food coating machine is very popular in Nigeria for nuts coating. It should be noted that peanuts need to be roasted in the peanut roasting machine before they can be coated.

The main structure of the sugar coating machine

The food coating machine is composed of several main parts such as a fuselage, a turbine casing, a sugar coating pan, a heating device, and a motor. It is driven by a motor through a pulley to drive the turbine, the vortex rod, and the sugar-coated pan to rotate. Under the action of centrifugal force, the material is tumbling up and down in the pot to make the sugar coating and the material fully mixed, thereby achieving good pilling and polishing effects.

This peanut coating machine is widely used in the rolling, mixing, and polishing of spherical granular materials in the food and chemical industries. It can also be used for uniformly coating and polishing the formed tablets in the pharmaceutical industry. The sugar-coated tablets have a bright, shiny surface. The surface of the sugar powder is crystallized to produce a complete consolidated coating, which can prevent oxidative deterioration, moisture, or volatilization of tablets and foods can cover the bitterness of the tablets when taken and is convenient for the human body to take and digest.

How does the candy coating machine work?

The new-designed candy coating machine controls the materials in the drum of the coating machine through the programmable control system to make complex trajectory movements continuously, continuously, and repeatedly. And during the movement process, the control system performs programmable control, and according to the requirements of the process sequence and parameters, the coating medium is automatically sprayed on the surface of the material by a spray gun, and the filtered hot air is provided by the hot air cabinet can penetrate the void layer of the material.

After the medium sprayed on the surface of the material is in full contact with the hot air, it will gradually dry. The exhaust gas is discharged from the bottom of the drum through the air duct by the exhaust fan so that the finished product forms a firm and smooth surface film.

Great advantages of food coating machine

- The automatic food coating machine is made of stainless steel, and the whole machine has a stable transmission and reliable performance. In addition, the machine is easy to operate, easy to maintain, and has high work efficiency, which can meet various process requirements.

- The chocolate coater machine is ideal for processing pharmaceutical, food, chemical, and other industries. It is suitable for processing coated peanuts, coated popcorn, coated cocoa beans, spiced peanuts, chocolate-flavored peanuts, plus spiced almonds, seasoned cashews, coated almonds, coated broad beans, and a variety of pills or tablets.

- This automatic coating machine has different models so it is suitable for many customers who have different requirements for coated food processing capacities. We can not only provide a high-quality coating machine but also can provide supporting equipment like a sugar spray tank, pump, and so on.

Technical parameters of the candy coating machine

| Model | Rotate speed(r/min) | Transmission power(kw) | Blower Power(kw) | Heating power(kw) | Capacity(kg/batch) | Size |

| TZ-400 | 28 | 0.37 | 180 | 1 | 2-5 | 900x500x1450 |

| TZ-600 | 28 | 0.75 | 180 | 1 | 5-10 | 900x600x1450 |

| TZ-800 | 28 | 0.75 | 250 | 1 | 10-20 | 1000x800x1500 |

| TZ-1000 | 28 | 0.75 | 250 | 2 | 20-30 | 1200x1000x1700 |

| TZ-1200 | 22 | 1.1 | 250 | 2 | 30-40 | 1300x1200x1800 |

| TZ-1400 | 22 | 1.5 | 250 | 3 | 40-50 | 1550x1400x1850 |