Commercial Pasta Machine | Pasta Noodles Maker Machine

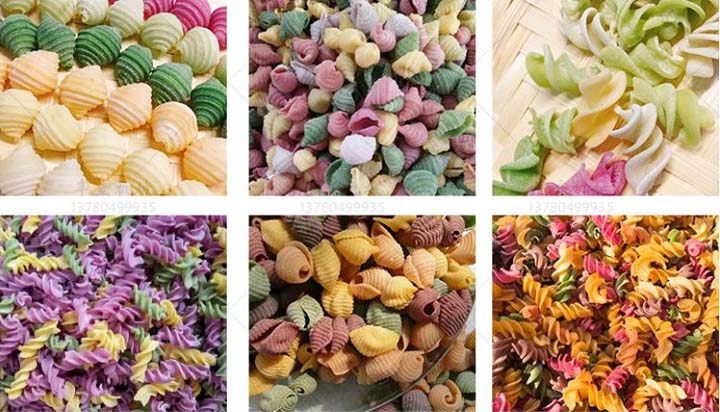

The commercial pasta machines (also known as shell crisp machine, pasta making machine, commercial pasta maker, etc.) are the food processing equipment that is popular among many users. This electric pasta maker machine uses flour dough(also can use rice flour, starch, miscellaneous grains, etc.) as raw materials, and produces various kinds of delicious pasta foods by high-temperature extrusion with different molds, such as shell crisp, cat ear crisp, white fungus crisp, five-star crisp, casserole, lantern crisps and other delicious and refreshing foods of different shapes. At the same time, this pasta maker can also produce a series of noodles such as hollow noodles, screw noodles, macaroni, ramen, and vegetable noodles.

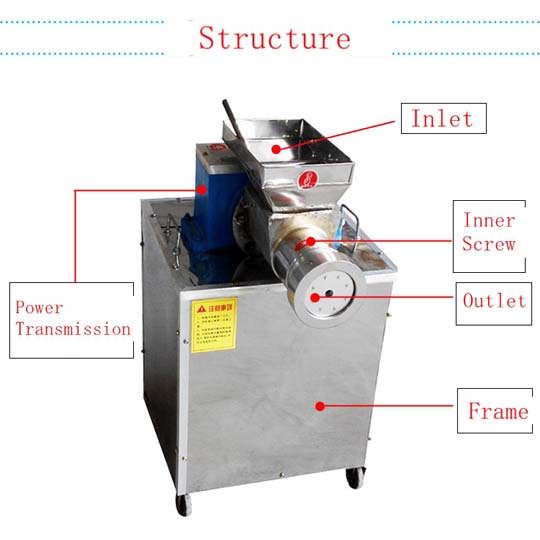

Electric pasta maker machine’s brief description

The pasta maker is mainly used to extrude flour and rice flour which are blended in a certain proportion into a variety of shapes and sizes. The finished pasta products then can continue to be processed into fried, spicy, grilled, spiced, and other flavored foods.

In addition, the finished product of this commercial pasta machine can also be boiled and eaten, adding soup to become a specialty snack. The raw materials of the pasta machine can be produced by one of or a mixture of flour, rice flour, and other ingredients. This machine can be operated by one person, with high output and considerable benefits.

Pasta machine’s use and maintenance

- Before using the pasta extruder, use a special wrench to open the nut and take out the spiral rod, and wipe the surface barrel and the spiral rod clean. Then insert the spiral rod into the sleeve and align the drive key on the spiral rod with the “turn sleeve” slot.

- After the other materials such as dry slag in the knives and noodle knives are soaked in water, clean them by vibration. Be careful not to clean them with a hard tool. After cleaning, select the ideal tool to fit on the front end of the mold, screw on the nut, and tighten with a special wrench.

- After connecting the power supply, start the pasta maker to idle for a few minutes, and when there is no abnormal sound, you can use it.

Main advantages of the electric pasta maker

- All parts in this pasta machine are made of stainless steel, which cannot only ensure the pasta food quality but also can make sure it has a long service life.

- This pasta roller machine is manufactured with precision, beautiful appearance, convenient use, low cost, low power consumption, and high output. It is the most ideal food machine for making money.

- We can provide the customers with different kinds of molds for making different pasta products, we can also customize the shape for customers and provide a variety of recipes for making pasta foods.

Commercial pasta machine’s technical parameters

| Model | TZ-60 | TZ-80 | TZ-100 | TZ-130(single-head) | TZ-130(double-heads) |

| Voltage (v) | 220 | 380 | 380 | 380 | 380 |

| Power (kW) | 1.5-2.2 | 3kw | 4kw | 5.5 | 11 |

| Weight (kg) | 70 | 80 | 100 | 300 | 600 |

| Dimension (mm) | 420*600*760 | 500*700*800 | 500*750*900 | 1000*900*700 | 1500*1000*850 |

| Output (kg/h) | 15-20 | 30-50 | 60-70 | 75-110 | 150-220 |