Hydraulic Oil Press | Oil Extractor

The hydraulic oil press machine also can be called a seed oil extractor, peanut oil press machine, sesame oil press machine, palm oil press machine, hydraulic oil press, and so on. This kind of oil extracting machine is a special hydraulic oil press equipment for high oil crops such as sesame, peanut, walnut, palm, almond, soybean, rapeseed, oil sunflower, pine seed tea seed, and so on.

This hydraulic oil press machine can directly press out the oil after adding the hot frying raw materials into the pressing barrel, which has the advantages of a simple process, high oil yield, and high oil extraction efficiency.

What is the oil pressing craft in the hydraulic oil press machine?

The hydraulic oil press is equipped with a temperature control system. This oil press machine can discharge oil under high pressure and high temperature. According to the driving power source of the oil pump, it can be divided into manual and electric. According to the way of applying pressure on oil, it can be divided into vertical oil press and horizontal oil press. In Taizy Food Machinery, we also have screw oil press for customers to choose from.

Technical parameters of the peanut oil expeller machine

| Model | TZ-150 | TZ-180 | TZ-230 | TZ-260 | TZ-320 |

| Dimension(mm) | 400*500*850 | 500*650*1050 | 600*850*1360 | 650*900*1450 | 800*1100*1550 |

| Weight(kg ) | 250 | 750 | 1050 | 1400 | 2000 |

| Pressure | 55 | 55 | 55 | 55 | 50 |

| Heating ring power(kw) | 2 | 2 | 2 | 2 | 2 |

| Heating ring temperature(℃) | 70-100 | 70-100 | 70-100 | 70-100 | 70-100 |

| The capacity of the barrel(kg) | 2 | 4 | 8 | 11 | 15 |

| The diameter of the cake(mm) | 150 | 180 | 230 | 260 | 320 |

5 different output hydraulic oil press machines for different needs. If you are looking for a high-quality hydraulic oil extractor, welcome to contact us via WhatsApp or email.

Working principle of hydraulic oil extractor

A cylinder is fixed on the base of the vertical hydraulic oil press, and a cylindrical piston is installed in the cylinder. The upper part of the piston is connected with the bearing plate as a whole, which will pre-press the raw material into a round cake. 20-40 round cakes can be stacked between the bearing plate and the top plate.

The two cakes are separated by a thin plate with holes, and then the piston is driven upward to generate pressure and squeeze the cake material out of the oil. After pressing, the oil pump stops pressurizing and the piston will drop. After the slag cake is discharged, the raw material cake can be loaded again to press oil.

Cod oil press craft and hot oil press craft

Cold oil press craft

The cold press for oil extracting is very suitable for pressing oil from pine nuts, almonds, olives, walnuts, camellia, macadamia nuts, and all kinds of condiments and Chinese medicines like pepper, mustard seed, basil, etc. For this type of oil pressing, the raw materials are fed into the oil press without heating or at a low temperature (40-60℃). The pressed oil has a lower temperature and a lower acid value generally does not require refining and is precipitated and filtered to obtain the finished edible oil.

Hot oil press craft

Sesame, flax, peanut, rapeseed, wheat germ, corn germ, and other raw materials are generally processed through the hot oil pressing process. Before oil extraction, these raw materials should be cleaned, crushed, and then subjected to high temperature(120-130℃)heat treatment to cause a series of changes inside the materials: destroying the oil cells, promoting protein denaturation, reducing the viscosity of the oil, etc., so as to be suitable for pressing oil and improving materials’ oil yield.

The main differences between the cold oil press and the hot oil press

- Cold-pressed oil can ensure that the various nutrients of vegetable oil are not destroyed, the content of unsaturated fatty acids is high, and the residues of harmful substances such as acid, alkali, heavy metals, and cholesterol are effectively eliminated so that the oil is clear and the smell is natural and fragrant. The cold oil press can ensure the original tastes and flavors of the oil.

- Most of the vegetable oils consumed in life are hot-pressed oils. Because most of the raw materials are not suitable for cold pressing, such as the soy flavor of soybean oil, the spicy taste of canola oil, the gossypol toxin in cottonseed oil, and the aflatoxin in some metamorphic oils. After hot pressing and refining, it can be removed. The scent of sesame oil and peanut oil must be obtained through hot pressing.

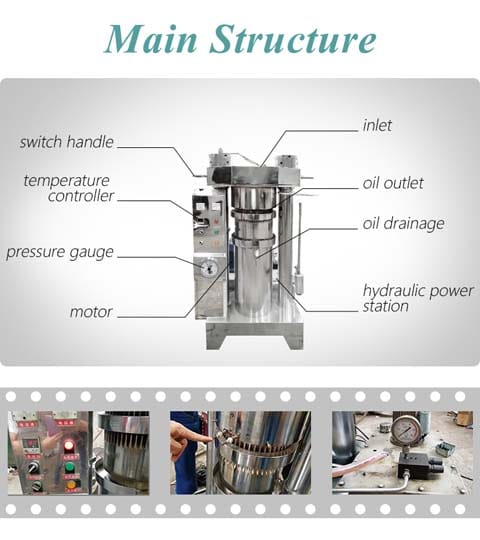

Structural features of the electric oil extractor machine

The automatic hydraulic oil press is a small oil press with simple operation, high oil yield, and fewer wearing parts than the mechanical oil press. It is an advanced oil press equipment that replaces the small grinding of sesame oil manually. The whole machine is mainly composed of three parts: 1. Host body. 2. Transmission hydraulic pressure. 3. Electrical control system.

Main body part

It is composed of the base, column, upper top plate, press barrel, oil pan, nut, and other parts, which are one of the main bodies of the whole machine. The oil material is in the press barrel and is pushed upward by the force of the oil cylinder, and the oil flows down from the oil flow port on the wall of the barrel and passes through the oil receiving plate to the oil storage barrel.

Transmission hydraulic part

This is the main working power source for the oil It is composed of a transmission shaft, worm gear, worm, gear pump, high-pressure pump, relief valve, manual control valve, cylinder assembly, pipe joint, and other parts. This hydraulic oil press adopts the famous brand hydraulic pump station-Korea three-piston pump station, which has the advantages of low speed, high oil pressure, and high-temperature resistance. The pump station can work continuously without an oil cooling device at an oil temperature of 65 degrees or more.

Electrical control section

It consists of motors, voltmeters, temperature control adjustment tables, pressure gauges, power insurance, and other components.

Operating procedures of the sesame oil extracting machine

- Clean the hydraulic tank and add 46# and 68# hydraulic oil.

- Check if the bolts in all parts are loose.

- Check that the line wiring of the hydraulic oil press is correct and connect the ground wire.

- After the power is turned on, the automatic temperature control switch is raised to about 70 degrees. First, put the mat on the lower hole plate inside the barrel, then put the fried raw material into the barrel, put it on another mat after filling it up, put the partition board, close the top board, and start pressing.

- When the gauge pointer rises to 50 MPa, the electrical control system will automatically stop. When a small number of oil leaks out of the barrel, the pressure gauge pointer will drop to 46 MPa. At this time, the electrical control system starts automatically, the pressure rises again, and the barrel has no oil seepage, which means that the oil in the barrel has been cleaned.

- Hold the reversing valve handle when releasing the pressure and slowly place it in the lowered position, so that the cylinder is lowered to a position about 100 mm from the top. Then place the reversing valve in the middle vacancy and pull the upper top plate to remove the oil cake.

- Place the reversing valve in the raised position so that the faceplate on the top plate of the piston is about 5 mm above the plane of the barrel. Then adjust the position of the reversing valve to the middle position, take the upper spacer plate and the mat, and take out the cake.

- Then place the reversing valve in the lowered position to allow the piston to descend rapidly and prepare for the second press.