Screw Oil Press | Oil Expeller

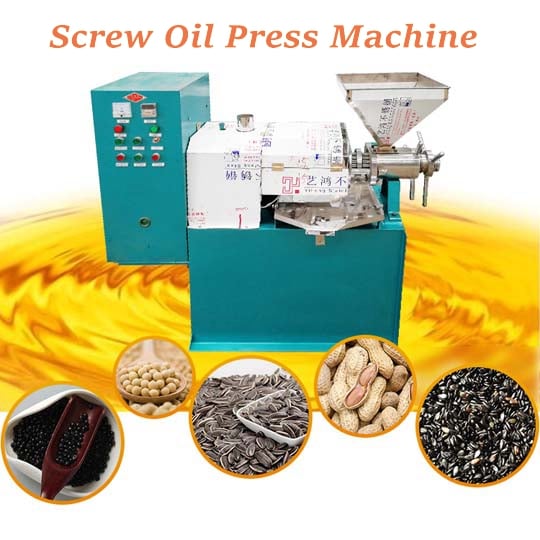

This multi-functional oil press machine also can be called the oil expeller or screw oil press, is a commercial type of oil-squeezing equipment for mass production of all kinds of vegetable oil. Compared with the hydraulic oil press machine, this screw oil pressing machine has a larger yield for oil production. This high-stability oil extraction equipment is also suitable for cold oil press and hot oil press craft.

What is the screw oil press?

Just like the hydraulic oil pressing machine, this automatic screw-type oil press is also a common oil extracting machine in many edible oil processing plants and oil workshops. The design model of the screw oil press can be small, medium, and large, which can meet all the needs of small oil mills, large oil mills, and edible oil processing enterprises. The production principle of this oil expeller is very simple, mainly by using the mutual squeeze friction between the machines to break the raw material crops and generate heat to obtain the oil components therein.

Pretreatment of the raw materials for oil extraction

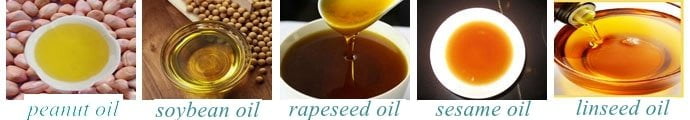

- Raw materials like sesame, peanut kernel, soybean, rapeseed, and so on should be cleaned, sieved, destined, or crushed first to ensure the oil quality.

- According to different raw materials, choose the corresponding pretreatment process before pressing: cold oil press or hot oil press.

Cold oil press: the materials don’t need to be fried at a high temperature before adding to the oil press machine. And the processing temperature is about 40-60℃. Suitable materials: pine nuts, almonds, olives, walnuts, camellia, macadamia nuts, and all kinds of condiments and Chinese medicines like pepper, mustard seed, basil, etc.

Hot oil press: the materials should be fried at a temperature of 120-130℃ in the special frying pot to reduce oil viscosity and increase the oil yield of the materials. Suitable materials: sesame, flax, peanut, rapeseed, wheat germ, corn germ, and so on.

Main parts of the screw oil pressing machine

The commercial screw oil expeller machine has a compact and reasonable structure, which is mainly composed of the electric control cabinet, heating press section, adjustment section, transmission section, and vacuum oil filter section.

- Electric control cabinet: it is composed of an air switch, AC contactor, temperature controller, and automatic circuit protection device.

- Heating press section: it mainly includes the heating ring, squeezer, and press rows.

- Adjustment section: this part is mainly composed of the adjusting screw, adjust nut, handle lock nut, etc.

- Vacuum oil filter section: this section mainly includes two parts: the vacuum pump and the oil filter.

Spare parts1 Screw rod Spare parts2 Press screw

How does the automatic oil expeller machine work?

The power transmitted from the main motor is transmitted to the main shaft by the reducer. The screw pressed on the main shaft is rotated to push the materials between the spirals forward. The pressure increases as the space between the pressing chamber and the screw shrinks and the density of the material increases.

In the process of oil pressing in this screw oil press machine, friction between soil particles and between materials and parts produces heat, which constitutes the pressure and heat of the oil pressing process. This can destroy the material cell tissue, and improve the oil yield. Eventually, the oil spills from the oil line, and the oil residue and cake are pushed out between the screw cone and the cake outlet.

When the spilled oil flows into the oil drum of the oil expeller machine through the oil tray, the vacuum pump will pump out the air in the drum, forming a negative pressure in the drum. The oil will be pumped into the oil drum through the press cloth, and the oil residue will be isolated on the press cloth to obtain pure oil.

The oil yield of different materials in this electric oil extractor machine

| Material Item | Oil extraction rate(%) | Dry residual oil rate(%) |

| Sesame | 42-55 | ≤7 |

| Peanut kernel | 40-50 | ≤8 |

| Rapeseed | 28-38 | ≤8 |

| Sunflower seed | 30-38 | ≤8 |

| Soybean | 10-16 | ≤7 |

How to maintain the screw oil press machine?

- The screw oil extracting machine should stop and check the lubrication after every 50 hours of operation. The oil cup on the top of the gearbox must not be short of oil. The inner shaft of the screw shaft should be filled with grease once per shift from the adjusting screw hole. Dry grinding is strictly prohibited.

- The oil parts of the oil-squeezing machine should be protected from dust and other impurities. Check the oil quality of the gearbox once a year. If the oil is found to deteriorate, replace it with new oil.

- When the pressing amount of the machine is reduced and the cake or oil is not normal, the screw shaft should be pulled out to check the wear of the screw, the strip, and the cake ring, and the worn parts should be replaced in time.

- After the end of each shift of the screw oil press, the residual cake in the machine should be removed and the dust and grease on the surface of the machine should be wiped clean.

- When the oil press is stored for a long time after the end of the production season, the machine should be maintained once, and the screw, the squeeze bar, the cake ring should be removed and washed, and the oil should be placed in a dry place.

The main features of the multi-functional oil squeezing machine

- High oil yield: The machine is cleaned together, saving labor and time. The machine is equipped with small power, adopts directional pressure, and multi-stage propulsion, and the oil yield is increased by 10-30%. The oil quality is pure, and the machine is multi-purpose. It can be used for more than 20 kinds of materials oil pressing, such as sesame, peanut, rapeseed, soybean, oil sunflower flax, and so on.

- Safe and convenient: The oil press has a compact structure and takes up less space; the production site can be used up to 10-20 square meters. The machine adopts fully enclosed protection, which is safe and convenient to operate. The machine is complete with supporting parts, can be produced by electricity, and is easy to operate. It is a must-select product for the oil extraction industry.

Technical parameters of the oil press machine

| Model | Power(kw) | Capacity(kg) | Voltage(v) | Overall dimensions(mm) |

| TZ-50 | 1.5 | 30 | 220 | 850x720x1030 |

| TZ-60 | 2.2 | 70 | 220 | 1280x880x1220 |

| TZ-70 | 3 | 130 | 220/380 | 1400x900x1260 |

| TZ-100 | 7.5 | 400 | 380 | 1900x850x1680 |

| TZ-125 | 15 | 600 | 380 | 2100x920x1700 |

| TZ-125 | 15 | 200-300 | 380 | 1950x1300x1700 |

| TZ-150 | 30 | 500-600 | 380 | 2200x1400x1700 |