Automatic Pomegranate Peeling Machine

Pomegranate automatic peeling machine is an important processing machine for making pomegranate wine and pomegranate juice. It is one of the special equipment for the deep processing of pomegranate. This pomegranate peeling machine is mainly used for the separation of skin and seeds from the pomegranate. The commercial pomegranate peeling machine can automatically separate the pomegranate skin from the pomegranate seeds, and do the preparatory work for the subsequent pomegranate seed juice extraction and pomegranate wine brewing. It is the necessary equipment for the pre-processing of pomegranate juice extraction.

Pomegranate peeling machine working video

Pomegranate peeling machine working video

Pomegranate peeling machine description

We all know that the pomegranate is a fruit with high nutritional value and a delicious taste. However, it is not an easy thing to crush or peel the pomegranate and pick its seeds. Therefore, where there are needs, there is the market. Our Taizy pomegranate peeling machine was greatly welcomed as soon as it went public for its high efficiency in crushing the pomegranate and picking the seeds.

Classification of pomegranate peeling machines

The pomegranate peeling machines manufactured in our factory are mainly divided into alternative types, one with a first-stage crushing function, and the other with a two-stage crushing function. The processing efficiency of the two-stage broken pomegranate peeling machine is higher and the processing effect is better.

The main structure of the pomegranate deseeder

The pomegranate seeds removing machine is mainly composed of a feeding hopper, a crushing chamber, a frame, a shroud, a separating shaft, a rotating screen, a transmission system, an electric control cabinet, and so on.

- Feeding:

Pomegranate can be fed into the hopper via a hoist or manually.

- The crushing device:

The crushing chamber is installed on the upper part of the pomegranate peeler machine and it can be the two-layer structure for crushing the pomegranate enough. The crushing roller of the crushing device is made of stainless steel, and the gap between the two rolls can be adjusted between 10-20mm.

Single-layer crushing: driven by a separate crushing motor, the distance between the two crushing rollers is 20MM (adjustable), and the material of the crushing roller is 304 stainless steel.

Double-layer crushing: The upper and lower two-stage crushing are driven by the same motor. The distance between the lower crushing rollers is 10MM (adjustable), and the material is nylon rubber.

- Separation device:

The device consists of a separation shaft, a separation screen, and a transmission system. The separation shaft is provided with a spirally distributed separation blade; the separation rotary screen is formed by punching a stainless steel plate, and its function is to separate the peel and the fruit seeds; the transmission system is located at the front end of the frame for decelerating frequency control, through the sprocket set Drive the separation shaft and separate the rotary screen.

The crushed pomegranate pieces fall onto the conveying screw and enter the screen cylinder. Then it is broken up by the mace device in the barrel to form the skin and seed separation. The pomegranate seeds are thrown out through the holes due to the centrifugal force and are conveyed to the pomegranate seed discharge port by the screw outside the sieve cylinder, while the pomegranate skins are left in the sieve cylinder and transported to the pomegranate peel discharge port for discharge.

- The rack(machine frame)

The frame is the support part of the various parts of the coupling device, all made of high-quality stainless steel.

- Electrical control cabinet:

It is assembled from cabinets, electrical components, frequency converters, etc., used to control the feeding (pre-set for the feed hoist), the opening and closing of the motor of the crushing and separating device, and the adjustment of the motor speed.

How to get seeds out of pomegranates automatically?

The pomegranate enters the upper crushing device from the feeding hopper, and the pomegranate is crushed and cut into several small pieces through the relative pressing of the crushing roller and the crushing action of the blade on the roller. Then, the crushed pomegranate pieces enter the lower crushing device for a second crushing.

The lower crushing roller of the automatic pomegranate crushing and seed picking machine is made of non-toxic and highly elastic rubber, and the damage to the pomegranate seed is small, and the gap between the two rolls can be adjusted between 15-22 mm. After two stages of crushing, the pomegranate that has been separated by the basic skin and seeds falls into a separation device (separation shaft and rotary screen combination) equipped with variable frequency speed regulation.

Under the rotation of the separation shaft and the rotary screen, the pomegranate seeds and part of the juice leak from the sieve hole(the diameter of the sieve hole is 13-16 mm), and enter the next process through the discharge port (transferred to the juicer or other by screw pump); the pomegranate peel is discharged from the tail of the device in the pomegranate peeling machine.

Working principle of Taizy pomegranate peeling machine

First, the whole pomegranate enters the upper crushing device from the feed hopper and is crushed and broken into several small pieces by the relative squeezing of the crushing roller and the cutting of the blade on the roller. The crushing roller of the upper crushing device is made of stainless steel, and the gap between the two crushing rollers can be adjusted according to the different sizes of pomegranates.

The crushing roller has little damage to the pomegranate skin seeds, and the gap between the two rollers can be adjusted between 10-20mm. After crushing, the pomegranate that has been basically separated from the skin and seeds falls into a separation device (a combination of separation shaft and rotary sieve) equipped with frequency conversion speed regulation.

Under the rotation of the separation shaft and the separation device, the pomegranate seeds and part of the juice are removed from the sieve. The hole leaks and enters the next process through the discharge port (transported to the juicer by the screw pump); the pomegranate peel is discharged from the tail of the equipment.

How to install a pomegranate peeling machine correctly?

- Before installation, check the equipment for damage or missing parts during transportation.

- The pomegranate peeling machine installation site should be hardened and ensure good drainage performance.

- The feeding mode of the equipment, the conveying method of the dregs, the water supply, and the drainage method are designed by the user.

- If the ground is flat, this peeler machine does not need to be fixed. It can be fixed by four M16 expansion bolts.

The main features of the pomegranate crushing and peeling machine

- The pomegranate peeling machine is made of food-grade 304 stainless steel, and the material is excellent. The thickness of the steel plate is strictly manufactured according to the enterprise standard. The outer casing of the machine is frosted and the lines are fine. The overall frame design is reasonable, the footprint is small, the output is large, the appearance is harmonious and beautiful, and the operation is smooth.

- This peeler machine minimizes the breakage of pomegranate seeds and retains more pomegranate seeds. It not only retains the original taste of pomegranate juice but also has a damage rate of less than 3%. This ensures that the pomegranate juice is rich in high nutritional value and avoids the bitter taste.

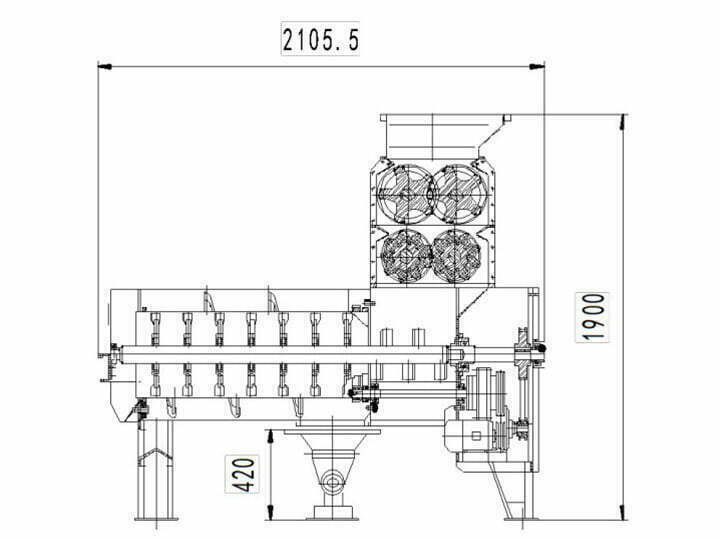

Technical parameters of the electric pomegranate peeling machine

| Model | TZ-P1 | TZ-P2 | TZ-P3 |

| Output | 1-1.5T/h | 5T/h | 3T/h |

| Rotary sieve diameter | 350mm | 800mm | 500mm |

| Power | 3.3kw | 7.7kw | 5.2kw |

| Overall weight | 350kg | 1200kg | 600kg |

| Dimension | 2600x610x1800mm | 3100x1100x2300mm | 2600x810x2000mm |