Almond Slicer Machine for Slicing Nuts

The almond slicer machine also can be called a nut slicer. It is the efficient nuts slicing equipment in the aspect of food processing. The almond slicing machine can be used to slice all kinds of nuts, such as cashews, almonds, peanuts, hazelnuts, etc. The sliced nut kernel pieces can be widely used to make a variety of exquisite foods such as cakes, desserts, ice cream, and various snacks.

We all know almonds have hard shells. In our company, we have an efficient almond shelling machine that can help you to remove the hard shell of almonds quickly. If you need this machine, you can also contact us.

Almond slicer working video

Wide applications of the almond slices

With the continuous research on healthy food, people pay more and more attention to the nutritional mix and color matching of food. Nowadays, we can often see that the surface of various types of cakes and ice cream is decorated with peanut flakes or almond flakes.

This method of food production not only ensures the new color style of the food but also makes the food more nutritious. So that the almond or other nut slices can be widely used in food processing fields.

Brief introduction of the almond slicer machine

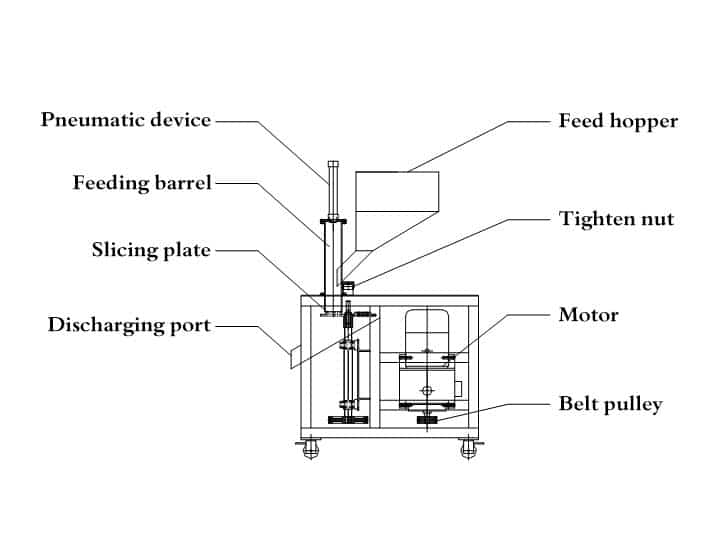

This multi-functional almond slicing machine or nut slicer is ideal for making nut slices. The slice thickness of the nuts can be adjusted between 0.3 mm and 2 mm. This almond slicing machine is composed of the main body, the driving motor, the feeding hopper, the electric controller, the pneumatic device, and the inner slicing system.

Raw materials like cashew nuts, almonds, and peanuts should not be too dry or too wet and they can be roasted before being sliced into pieces. By the way, our company has a special almond shelling machine for removing almond shells.

The sliced nut pieces can be used for food processing directly. When using this almond slicer machine, we should add the nuts into the feed hopper manually at an even speed. When the nuts fall into the automatic slicing system, these nuts will be sliced into thin flakes very quickly. After nut slicing, these nut pieces will be discharged from the machine outlet. The nut slicing thickness can be adjusted according to actual production requirements.

Use precautions of the nut slicing machine

1. How to install and debug the peanut slicer?

After the almond slicer is installed, turn on the power and observe that the spindle of the machine is turning correctly. The correct direction is to turn clockwise. The motor of the slicer uses an electromagnetic speed control motor, so the speed of the cutter head can be adjusted according to the actual requirements of the material. Please note that the speed controller should be returned to zero every time the machine is turned on and off to avoid damage to the governor.

When connecting to the air source of the air compressor, use an 8 mm outer diameter air pipe to connect clean compressed air from the pressure regulating valve and adjust the air pressure to 0.3-0.4 MPa.

Then adjust the operating frequency of the cylinder. The lifting time of the cylinder is generally 3-4 seconds. The cutter speed is generally adjusted to 15-30 seconds. The pressing time should be set according to the specific requirements so that it is suitable to completely cut the material in the barrel.

2. How to adjust the almond slicing thickness?

Continuously sectioning can be carried out by adding selected and cleaned nuts from the hopper. When changing the thickness of the nut slice, the lock nut under the handle can be adjusted. Adjusting the handle in a clockwise direction increases the thickness of the slice, and conversely reduces the thickness of the slice.

The rotation of the slice automatically sets the slice thickness to 1.5 mm. Customers can also adjust according to their actual requirements. After adjusting, re-lock the regulation nut.

3. How to replace the slicing blades of the almond slicer?

This almond slicer is equipped with two high-speed stainless steel blades on the rotating cutting disc. When the edge of the blade is blunt and not sharp or there is a defect when the nut is mixed with sand or small stones, the blade must be replaced.

When changing the blade, open the front door of the discharge port, and then open the round cover on the surface of the machine. Use a hexagon socket bolt wrench to remove the two M6 bolts of the lock blade from the underside of the rotary cutter. Remove the blade and reinstall the new blade.

Technical parameters of the nut slicer machine

| Name | Almond Slicer Machine |

| Power | 1.5KW |

| Voltage | 3P/380V |

| Output | 50-200KG/H |

| Air pressure | 0.3-0.4Mpa |

| Dimension | 1000x550x1500MM |

The output of the Taizy nut slicer is 50-200kg/h. This output can be adapted to most nut slicing needs. The power of the machine is 1.5KW. Do you need this multifunctional almond slicer? Feel free to contact us if you need it.