Peanut Sesame Brittle Bar Cutting Machine | Forming Machine

The commercial peanut brittle cutting machine is important equipment in the peanut brittle production line. It mainly compacts the evenly stirred peanut brittle, forming and cutting it into peanut brittle bars of the same size. This peanut brittle bar forming machine can not only cut peanut brittle bars but also can process sesame brittle bars, nuts brittle bars, etc. The main functions of the peanut candy cutting machine are automatic transmission, cooling, cutting, and so on, which is very useful for the peanut sesame brittle bars processing plant. This peanut candy brittle forming machine has a variety of models, and the output is between 300kg/h to 1500kg/h. We can recommend suitable peanut candy forming machines for customers according to their production needs.

Why use the peanut brittle bar cutting machine for processing peanut brittle?

In the large-scale production of peanut candy in food processing plants, we usually use the peanut brittle bar forming machine to cut whole pieces of peanut candy into uniform-sized bars or cubes. The finished products processed by a peanut brittle cutter machine can be packaged into various exquisite packages, which is more attractive to consumers.

If peanut candy brittle forming and cutting machine is not used, peanut candy processors can only use manual cutting methods. However, manual cutting is likely to cause the uneven size of the peanut candy and a high crushing rate. Moreover, the efficiency of manually cutting peanut candy bars is very low and laborious.

Structure of the peanut brittle bars forming machine

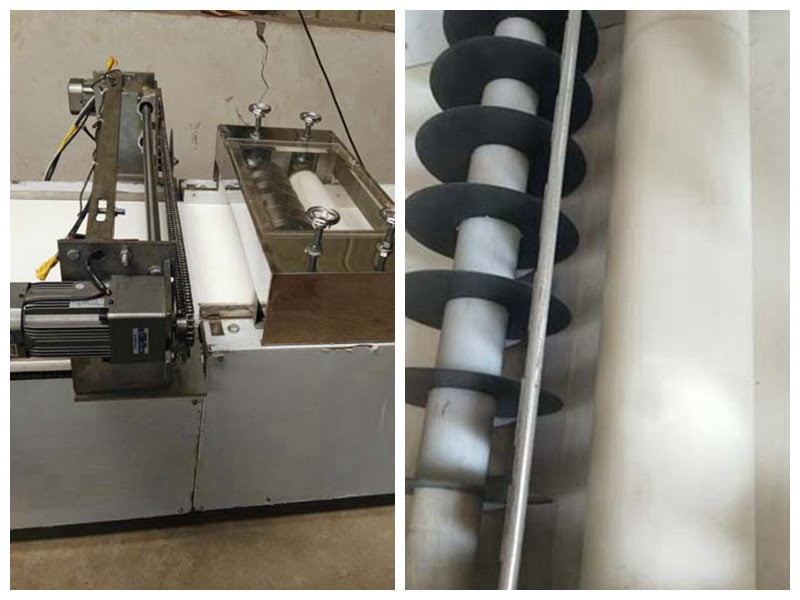

The peanut candy cutting machine is mainly composed of three parts: a pressing system, a cooling system, and a cutting system. It mainly has the functions of pressing, conveying, cooling, and cutting.

Pressing system

The front half of the automatic molding machine is mainly composed of a feed inlet, conveyor belt, pressure roller, fan, and so on. In addition, there are mixing blades and rotating shafts in the inlet, which can evenly press the relatively viscous peanut candy into the conveyor belt of the machine.

There are multiple sets of press rollers on the conveyor belt of the peanut brittle cutting machine, which can automatically press the peanut brittle on the mesh belt to make the density and thickness consistent.

The gap between the pressure roller and the mesh belt can be adjusted, so the user can change the density and hardness of the processed peanut candy by adjusting the position of the pressure roller when using the sesame brittle cutting machine.

Cooling system

If the temperature of peanut candy is very high during cutting, it is easy to cause adhesion to each other, which will cause difficulty in cutting. Therefore, we added multiple sets of cooling fans in the conveying part when manufacturing this peanut candy forming machine, which can quickly cool the finished peanut candy. There are two fans on the conventional peanut candy cutting machine, namely one set of fans. Multiple sets of fan cooling devices can be used on peanut brittle forming machines of different models and different yields.

Cutting system

The cutting system of the peanut candy cutting machine consists of two groups of cutting knives with different directions, namely, the horizontal roller cutter and the vertical chain cutter. The roller cutter can first cut the peanut candy into long strips of uniform width, and then the chain cutter can once again divide the peanut candy into uniform squares. Users can use different cutters to process peanut brittle bars of different sizes according to their needs.

Main features of the peanut candy brittle cutter machine

- This commercial peanut candy cutting machine is often used in the complete peanut candy production line and is paired with a peanut candy packaging machine to produce high-quality peanut candy snacks in large quantities.

- The machine is all made of stainless steel, which is very resistant to corrosion and wear and has a longer service life. The conveyor belt of the peanut sugar cutting machine is made of food-grade PE material, which is safe and hygienic, non-toxic, tasteless, and easy to clean.

- The automatic cutter machine can be used not only to process peanut brittle, but also to press and shape sesame brittle, nuts brittle, and other similar foods. The processing capacity of the machine is generally between 100kg/h and 2000kg/h, and customers can choose the appropriate model according to production needs.