Steam Jacketed Pans: Uses, Benefits, and Types

Steam jacketed pans are a versatile piece of equipment that can be used for a variety of purposes in the food service industry, industrial manufacturing, and laboratory settings. They are designed to heat liquids and other materials using steam, which provides several advantages over other heating methods.

What is a steam jacketed pan?

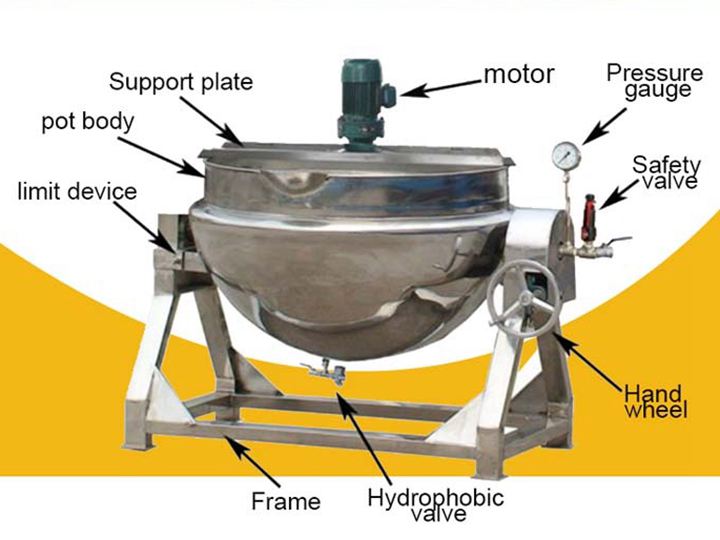

A steam jacketed pan is a type of cooking vessel that has a steam jacket surrounding the inner cooking chamber. The steam jacket kettle is connected to a boiler or other steam source, and the steam is circulated through the jacket to heat the contents of the kettle.

How does a steam jacketed pan work?

The steam in the jacket heats the outer surface of the cooking chamber. This heat is then transferred to the contents of the kettle by conduction. The steam jacket provides a uniform heat distribution, which is essential for many cooking applications.

Benefits of steam jacketed pots

There are several benefits to using steam jacketed pots. These benefits include:

- Uniform heat distribution: The steam jacket provides a uniform heat distribution, which is important for cooking delicate foods or for maintaining the temperature of a liquid.

- Energy efficiency: Steam is a very efficient way to heat liquids. Steam jacketed pots can save energy compared to other heating methods, such as direct gas or electric heating.

- Safety: steam jacketed pots are generally considered to be safer than other types of cooking vessels. The steam jacket helps to protect the user from burns.

- Ease of use: steam jacketed pots are relatively easy to use. They typically have a simple control panel that allows the user to adjust the steam pressure and temperature.

Steam jacketed kettle uses

Steam jacketed pans can be used for a variety of purposes, including:

- Cooking: this machine can be used to cook a wide variety of foods, including soups, stews, sauces, gravies, and desserts.

- Boiling: steam jacketed pans can be used to boil liquids quickly and evenly. This makes them ideal for boiling water, milk, or other liquids.

- Pasteurization: this machine can be used to pasteurize liquids and foods. This is a process that kills harmful bacteria and microorganisms.

- Sterilization: steam food processing kettless can be used to sterilize equipment and utensils. This is a process that kills all living microorganisms.

Types of steam food processing kettles

There are two main types of steam food processing kettless:

- Stationary kettles: Stationary kettles are mounted on a stand and cannot be moved. They are typically used in large commercial kitchens or industrial settings.

- Tilting kettles: Tilting kettles have a spout that allows the contents to be emptied. They are typically used in smaller kitchens or laboratories.

steam jacketed pans are a versatile and efficient piece of equipment that can be used for a variety of purposes. They are a valuable asset for any food service operation, industrial manufacturer, or laboratory.