Commercial Tofu Making Process and Manufacturing Plant Cost

Are you interested in setting up a tofu manufacturing plant? This article provides valuable insights into the commercial tofu making process and offers an overview of the associated costs. From the use of tofu machines to understanding the expenses involved in establishing a tofu manufacturing plant, we’ll cover all the essential aspects. Contents hide 1…

Are you interested in setting up a tofu manufacturing plant? This article provides valuable insights into the commercial tofu making process and offers an overview of the associated costs.

From the use of tofu machines to understanding the expenses involved in establishing a tofu manufacturing plant, we’ll cover all the essential aspects.

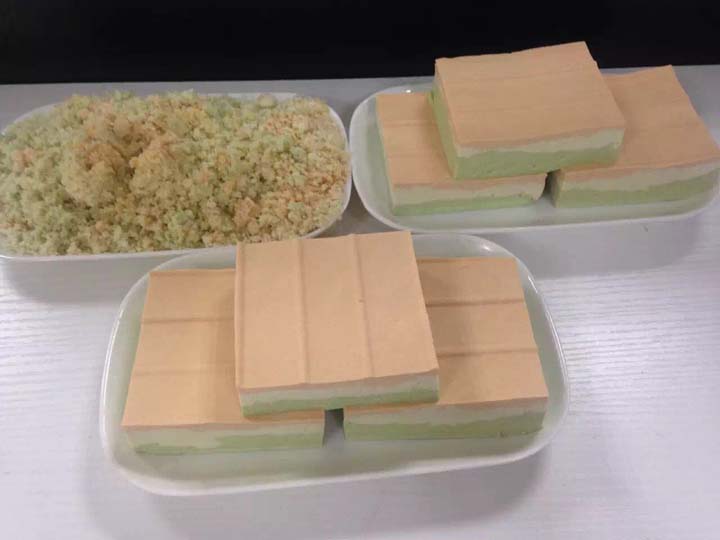

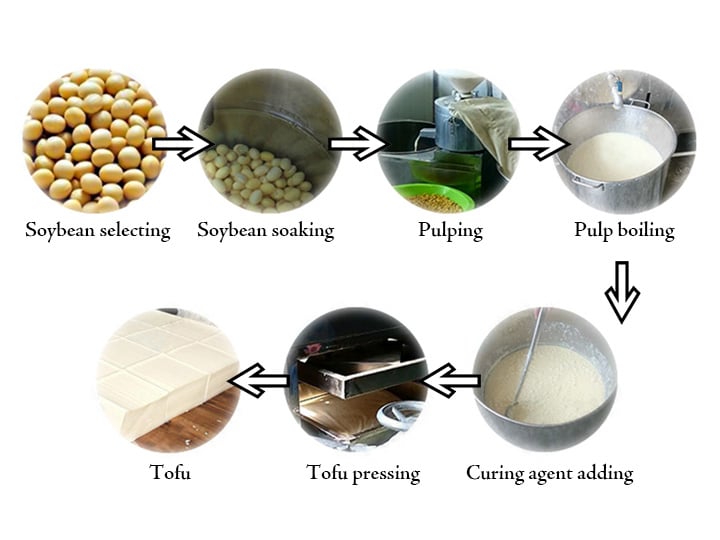

Commercial Tofu Making Process

Tofu production on a commercial scale involves several tofu making processes, which are as follows:

- Soybean Preparation:

Sorting and Cleaning: Selecting high-quality soybeans and removing impurities.

Soaking: Soaking the soybeans in water for a specific period to soften them. - Grinding and Extracting Soy Milk:

Grinding: Using grinding equipment to crush the soaked soybeans into a fine slurry.

Extracting Soy Milk: Separating the soy milk from the solid residue by filtering the slurry. - Heating and Coagulation:

Heating: Transferring the extracted soy milk to a heating system.

Coagulation: Adding coagulants, such as calcium sulfate or magnesium chloride, to the heated soy milk to facilitate curdling and coagulation. - Pressing and Molding:

Pressing: Applying pressure to the coagulated soy milk to remove excess liquid and obtain tofu curds.

Molding: Shaping the tofu curds into desired forms using molds or commercial tofu making equipment. - Cooling and Packaging:

Cooling: Allowing the freshly molded tofu to cool down to enhance its texture and firmness.

Packaging: Packaging the cooled tofu in appropriate containers, ready for distribution and sale.

Tofu manufacturing plant cost

Establishing a tofu manufacturing plant involves several cost factors, including:

- Infrastructure and Equipment. Factory Space: Acquiring or leasing a suitable facility for tofu production.Tofu Machines: Investing in commercial-grade tofu machines, such as soybean grinders, tofu coagulators, tofu presses, and cooling systems.

- Raw Materials and Ingredients: Soybeans: Procuring a steady supply of high-quality soybeans. Coagulants: Purchasing coagulants like calcium sulfate or magnesium chloride. Water and Packaging Materials: Factoring in costs for water supply and packaging materials.

- Workforce and Labor: Skilled Labor: Employing experienced personnel for operating tofu making equipment, quality control, and packaging. Administrative Staff: Hiring employees for managerial and administrative roles.

- Regulatory Compliance: Licensing and Permits: Considering expenses related to obtaining necessary permits, licenses, and complying with food safety regulations.

- Marketing and Distribution: Branding and Advertising: Allocating funds for promoting the tofu products in the market. Distribution Channels: Planning logistics and transportation for delivering tofu to retailers or customers.

Conclusion

Setting up a commercial tofu manufacturing plant involves a detailed understanding of the tofu making process and the associated costs. From sourcing soybeans to investing in tofu machines, infrastructure, labor, and marketing, careful planning and budgeting are essential for a successful venture. By following the steps outlined in this guide, you can embark on your journey to establish a thriving tofu manufacturing business.

Related Content

Tofu Maker Machine Shipped to the USA

Good maintenance methods of the tofu making machine