Features of the peanut butter production line

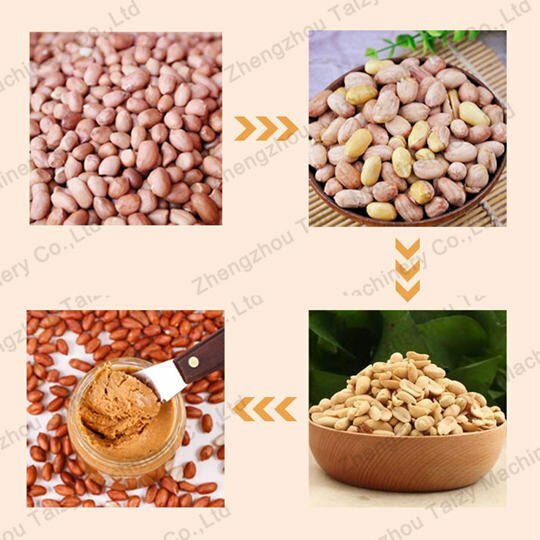

Peanut butter is a nutritious food supplement. High-quality peanut butter is generally light beige, delicate in quality, rich in aroma, and free of impurities. The peanut butter production line equipment developed by our Taize Machinery is a piece of equipment specially developed for sauce companies, which can meet the needs of automation and large-volume production of sauce manufacturers.

Peanut butter is divided into two types: sweet and salty. It is a nutritious food supplement. It is widely used in Western food. Peanut butter is processed from high-quality peanuts as raw materials. The finished product is hard and muddy, with a strong flavor of fried peanuts. . High-quality peanut butter is generally light beige, delicate in quality, rich in aroma, and free of impurities. The peanut butter production line equipment developed by our Taize Machinery is a piece of equipment specially developed for sauce companies, which can meet the needs of automation and large-volume production of sauce manufacturers.

1.Butter filling line

Our peanut butter production line can be applied to various metering filling production and can be adjusted according to customer needs. And there are no major restrictions on the materials. As long as it is sauce, it can basically be filled, such as high-viscosity products such as chili sauce, bean paste, sesame paste, and foods such as white wine, soy sauce, vinegar, condiments, vegetable oil, syrup, mineral water, etc. Liquid products and various liquid products in the daily chemical, pesticide and chemical industries. The whole set of peanut butter filling machinery is controlled by a microcomputer (PLC), which has the characteristics of high production efficiency and accurate measurement. At the same time, the structure is simple, compact, and easy to adjust, and the container of different specifications can be replaced in a short time. Using PLC control, stable and reliable operation, high production efficiency and strong applicability. The equipment of the peanut butter production line is made of stainless steel, which is not only beautiful but also can meet the packaging of corrosive liquids and foods with high sanitary requirements.

Technical advantages of filling machine equipment:

- Our bottle filling machine equipment manufacturer is a semi-automatic piston filling machine, equipped with automatic mixing function, simple structure, high accuracy, and easier operation. It is an ideal granular slurry viscosity fluid filling equipment;

- The filling valve is controlled by a pneumatic valve, the filling accuracy is higher, the filling volume and filling speed can be adjusted arbitrarily, and the filling head adopts anti-drawing and lifting filling devices;

- The filling head of the bottle filling machine equipment is equipped with an anti-drip device, and the filling has no drawing or dripping; it is filled with a bottle, and no bottle is filled;

- The actions of the filling machine equipment are stable and accurate, making it an ideal machine-electrical integration product at present.

2. Peanut butter production line

This peanut butter production line equipment is especially suitable for medium-sized particles with high concentration. It can also be filled with other seasoning products of the same concentration, such as bean paste, peanut butter, sesame paste, jam, butter hot pot base, red oil hot pot base, etc. A viscous seasoning filled with this substance. The automatic peanut butter production line is suitable for filling materials with obvious oil separation and uneven particles. It is ideal equipment for separating sauces. The material that this type of filling equipment contacts with the material is 316 stainless steel and silicon rubber that meet QS specifications. Moreover, the cleaning speed is fast, the adjustment is convenient, and the stepless speed regulation of the volume cylinder action is suitable for the filling of different specifications and different materials. After adjusting the filling volume once, each measuring cylinder can be adjusted slightly, with high filling accuracy and good consistency.

Summary of the advantages of the automatic peanut butter production line

- The equipment of the peanut butter production line includes man-machine interface and PLC communication, debugging equipment or changing varieties only needs to be set on the screen. After entering the bottle, positioning, filling and filling, the bottle will run automatically.

- If the bottle is not placed in the proper position during the filling process, the bottle will be blocked when the movable pipe is not inserted into the bottle. The device will automatically protect and continue to work after being removed.

- The imported electromagnetic clutch of the filling equipment is used in conjunction with the electromagnetic brake to eliminate the inertia and improve the filling accuracy.

- Fast cleaning speed, convenient adjustment, stepless speed regulation of volumetric cylinder action, suitable for filling different specifications and different materials. After adjusting the filling volume once, each measuring cylinder can be adjusted slightly, with high filling accuracy and good consistency. The material in contact with the material is 316 stainless steel and silicon rubber that meet QS specifications. Peanut butter production line equipment includes

- Imported gear reducer motor of automatic peanut butter production line stepless speed regulation filling plunger cylinder, not only suitable for all kinds of sauces, but also for pastes.