Electric Almond Shelling Machine

This almond shelling machine is practical nut processing equipment in many fields. The automatic almond shelling machine can be applied to remove the shells of almonds, hazelnuts, and other nuts.

This shelling machine can not only be designed for nuts peeling but also can realize the nuts sieving function for different specifications. In Taizy food machinery, we also have special peanut shelling machines and cashew nut shelling machines for sale.

What is the almond shelling machine?

The electric almond peeling machine mainly can crush the almond or hazelnut first, then remove the shells through its screen vibration, and then discharge the clean nut kernels and shells from different outlets.

This machine is mainly used to strip hard nuts of various specifications. It is the ideal nuclear processing equipment for hoist feeding, the first, second, and third level automatic screening of the broken shell, the composition of the discharge screen, and the vibrating screen at all levels, with reasonable design and low breaking rate. Multi-level shelling can also be designed according to the customer’s specific requirements.

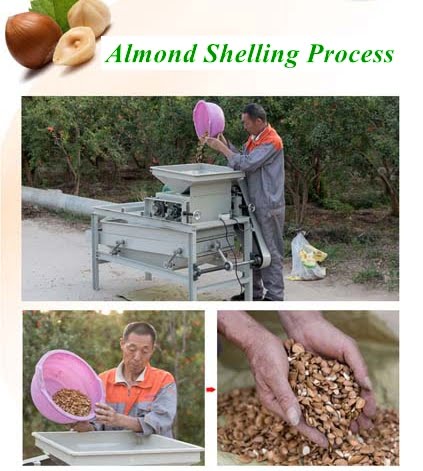

How to shell the almond with the almond sheller?

Almonds are fed into the hopper manually or by the conveyor of the sheller machine. The almonds are first rolled into the drum of the machine, and the almond shell and the kernel are peeled off due to the force between the rotation of the pattern and the concave plate of the shed. The peeled kernel and the shell are simultaneously dropped through the front concave plate hole. The broken almonds will fall on the vibrating plate with a mesh (a total of three levels).

As the three-stage vibrating plate continues to vibrate, the almond kernels will fall through the mesh holes into the material collection device. The larger almond shell will continue to drain from the discharge port.

This almond peeling machine is single-stage shelling equipment. After the apricot kernel is poured into the machine and the shell is broken, there are some unbroken almonds. After screening, adjust the gap of the shell breaker and then break the shell once.

The machine can also be customized as a three-level almond shelling, and the almonds can be divided into three grades in different sizes to complete the shelling. Because this almond shelling machine is specially designed, the almond peeling and sorting effect is good, shelling efficiency is high, and the breakage rate of nuts is low.

Almond shelling machine details

| Model | TZ-400 |

| Capacity(kg/h) | 400 |

| Power(KW) | 2.2 |

| Weight(kg) | 220 |

| Overall dimension(cm) | Power(kW) |

This almond shelling machine has an output of 400kg/h. This is suitable for most almond shelling requirements. Are you looking for a high-quality almond sheller machine? Welcome to inquire us.

What is the price of an almond shelling machine?

Searching for the best almond shelling machine price? Look no further! We offer a wide range of almond shelling machines at competitive prices. Whether you’re looking for a small, portable almond sheller or a large, industrial-grade machine, we have the perfect solution for your needs.

Compare our prices and features to find the perfect almond shelling machine for your business. Don’t settle for less, choose the best almond shelling machine at an affordable price today!

Precautions for use of almond peeler machine

- Before using the sheller, connect the 380v three-phase power supply, then start the motor to see if the running direction is the same as the direction of the machine indicator arrow. If it is different, you should adjust any two connectors in the power supply to achieve the same direction as the indicator arrow.

- The things that need to be peeled can not be too dry, the water content should be maintained at about 9%, otherwise, the breakage rate of nuts will increase. If you have any questions about the use of the almond shelling machine, please feel free to contact us.

- Before adding materials for production, separate materials of different varieties and sizes, and then install screens of appropriate specifications on the machine, which can greatly improve production efficiency and reduce the crushing rate.

- After the trial run of the machine, if all parts of the machine are running normally and there is no abnormal sound, it can be produced normally.