Soy Milk Machine | Tofu Making Machine | Tofu Maker

The integrated Taziy soya milk and tofu making machine is very practical for making fresh soymilk and tofu in large quantities. This automatic tofu machine is the newest type of commercial soybean milk and tofu production equipment.

According to the different customers’ actual use, our soymilk tofu making machine can be different types, such as the independent type of soybean milk machine and the tofu making machine, the integrated type of soymilk tofu maker, and so on. As for each type, there also can be many models with various production capacities to choose from.

Parameters of tofu making machine

| Model | Operating mode | Voltage(v) | Tofu capacity(kg/h) | Soybean milk capacity(kg/h) | Material | Weight(kg) | Size(mm) |

| Y0-60 | Manual operation | 220 | 30 | 120 | Stainless steel | 100 | 158.5×85.5×136 |

| Y0-60 | Air-operated | 220 | 30 | 120 | Stainless steel | 100 | 158.5×85.5×135 |

| Y0-100 | Manual operation | 220 | 50 | 120 | Stainless steel | 150 | 100.5×85.5×135 |

| Y0-100 | Air-operated | 220 | 50 | 120 | Stainless steel | 150 | 100.5×85.5×135 |

| Y0-200 | Air-operated | 220 | 100 | 120 | Stainless steel | 180 | 115x90x127 |

| Y0-300 | Air-operated | 220 | 100 | 240 | Stainless steel | 220 | 171x90x127 |

Tofu machines with output of 30-100kg/h are available for customers with different needs. Are you looking for a reliable tofu making machine? If so, feel free to contact us and we will reply to you as soon as possible.

Independent soy milk maker description

The stainless soybean milk maker is mainly to squeeze the soaked soybeans into the edible soymilk. It is mainly composed of a feeding funnel, water injection pipe, electronic controller, pulping machine, pulp boiling bucket, soymilk discharging outlet, and so on.

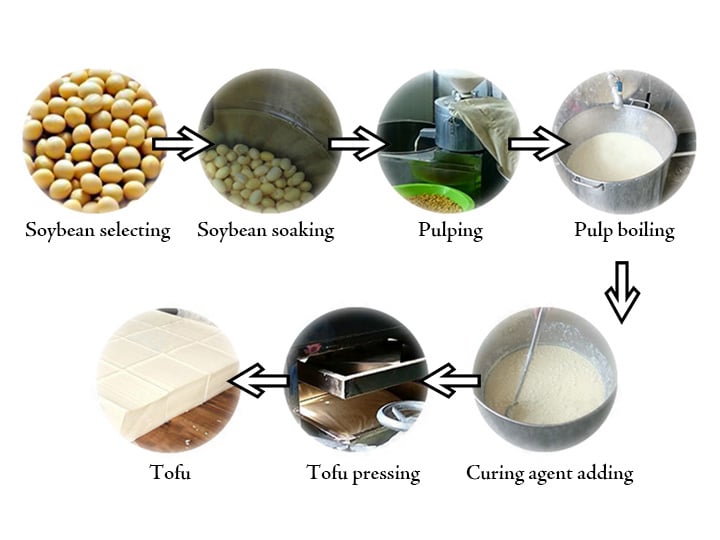

When using this soya milk maker, we should follow the next steps to make good soya milk. First, we should select good soybean which is clean and not damaged. Then soak the beans with water at a ratio of 1:12, 6 to 8 hours in summer and 8 to 10 hours in winter before making soybean pulp.

Soymilk making process in the soymilk maker

Put the well-soaked beans into the feeding funnel after turning on the switch of the electronic controller as well as the water injection pipe. Then the soybean will be continuously ground in the pulp grinding machine, and the raw soya pulp will flow into the pulp boiling bucket for further boiling. The bean dregs can be excluded and re-pulping. The final soya milk will be made after 5 minutes in the pulp boiling bucket with a boiling temperature of about 100℃.

The main features of the soya milk machine

- This soybean processing equipment can match the tofu press machine to make tofu.

- With different models, its working capacity ranges from 150L/h to 300L/h.

- All the parts are made of high-quality stainless steel which can ensure the original flavor of the soymilk and tofu.

High-efficient tofu maker

Tofu machines actually can be a set of machines as well as a single piece of tofu making machine, here we mainly introduce the former. Our best tofu maker can be divided into two types: the manual type and the pneumatic type. Each type of tofu making machine can make tofu very efficiently and they are very easy to operate so that one person can manage.

1. Manual type tofu making machine

The manual type tofu making machine has a very simple structure, which includes the supporting shelf, filter water tanks, water discharging outlet, pulp pressing box, press plate, and rotating handle. According to different requirements of the tofu processing capacities, and this machine can be designed with more than one pulp pressing box for making tofu.

When using this tofu making machine, we should cover the box with a large piece of gauze, and then put the boiled soya pulp on this gauze. When the box is full, we put the box on the shelf and rotate the handle for pressing. The water squeezed from the pulp will flow into the tank.

2. Pneumatic-type tofu making machine

The pneumatic type tofu maker is a little different from the manual type and it has a larger processing capacity. Based on the basic structure of the manual type, this tofu making machine uses the air pump pressing to replace the manual pressing.

This type can also be set to more than one tofu pressing box for large-scale production of tofu. There are switches of the air pump presser on each of the press units so that when we put the box on the shelf, we can just press the button and the tofu will be pressed. It is very convenient and suitable for tofu producers.

The integrated soymilk and tofu making machine

The soymilk and tofu processing equipment with an ex-factory price is the newest integrated type to make both soya milk and tofu. This soybean processing equipment is the simplified combination of the single soya milk making machine and the tofu press machine.

The main structure of this high-quality machine includes the water injection pipe, feeding funnel, electronic controller, pulping machine, pulp boiling bucket, soymilk discharging outlet, and the pulp press part. As for the pulp press part, which can also be the manual type and pneumatic type.

The main features of the soy milk and tofu maker machine

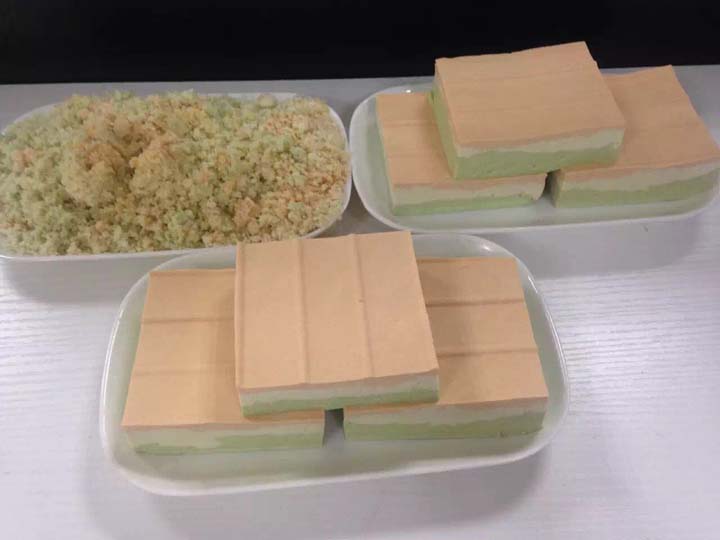

- Multi-purpose machine for producing soy milk, bean flowers, and various tofu products. We can also make the colored tofu by adding all kinds of vegetable juice into the soya bean pulp when pressing tofu by the tofu making machine. Besides, the soy milk cooking temperature in the cooker machine can be adjusted manually and the tofu press mold can also be changed with different patterns and letters.

- The small pulp boiling bucket uses a closed electronic high-temperature steam to heat the boiled pulp process, which can eliminate the harmful substances of soybeans on the human body and can dislocate and deodorize, maintain the original color of soybeans, and effectively prevent protein damage, and also avoid the scorch of soy milk, which can keep the original nutrients and taste of soy milk.

- Clean and hygienic: this stainless steel soya milk and tofu production equipment meets international food hygiene standards. It is simple, sleek, and easy to clean. During the soymilk and tofu making process, the ground is waterless and the environment is clean and hygienic. This commercial tofu maker is a good helper for most users having the tofu making business. Besides, the spare parts of these machines are also available in our factory.

- Convenient and fast: the machine uses automatic slurrying, saving time and effort. It has a small footprint, low failure rate, and is simple and convenient, from raw materials to finished products for about 30 minutes. As the food machine manufacturer and supplier, Taizy Machinery has developed many items for food machine processing so that our customers can get more proper options for food processing. And our engineers and technicians have been dispatched to many foreign countries to assist our customers and give them useful solutions.