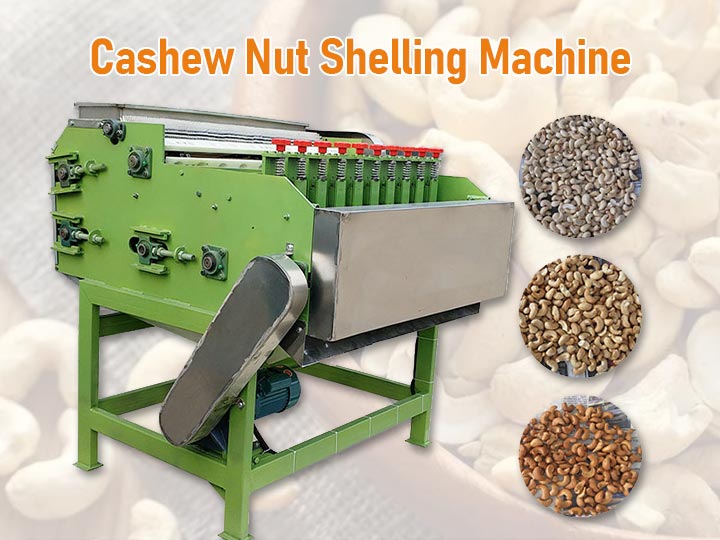

Automatic cashew nut shelling machine

Our automatic cashew nut shelling machine is specially developed by our company to be used to break the hard outer shell of cashew nuts. It is of high shelling ratio, low crushing ratio, high quality, simple operation, and easy maintenance. It can be used in the food processing industry or in the pretreatment of oil production plants. The machine can be adjusted to different sizes of cashew nuts.

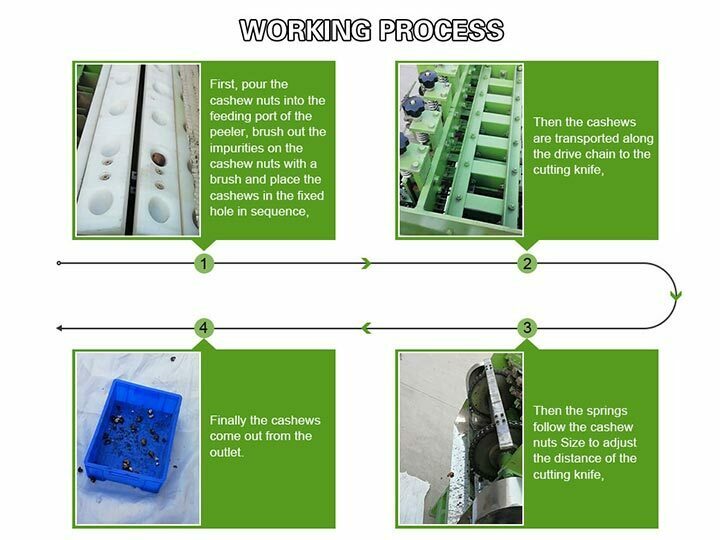

The principle of the cashew nut shelling machine

After the machine is running normally, put the cashew nuts into the hopper in a quantitative, uniform, and continuous manner. The material is crushed by rolling, shearing, and squeezing. Finally, pure nuts are obtained under the action of a shell and kernel separator composed of a fan and a vibrating screen.

How to get a better shelling effect?

Using our automatic cashew nut shelling machine, in order to get a better shell, we recommend steaming raw cashew nuts, drying them, and classifying them into at least 3 grades of raw fruit.

To open the shell with ideal effect, automatic shell opening machine: medium and large (the corresponding raw material for opening the shell is large and the fruit width is more than 23 mm), and the medium and small (corresponding to the raw material for opening the shell is the small and medium fruit, and the width of the fruit is less than 23 mm), The size of the feed mold has been matched, if the shell opening effect is not satisfactory, the customer can fine-tune the gap. Adjust the height of the knife body, and the depth of the blade in the knife body, and see the situation of opening the shell. The blade only cuts the nutshell and slightly cuts the kernel skin.

Tips for the cashew nut shelling machine

- Check the looseness of transmission parts and the existence of abnormal noise before running the machine.

- Check whether the wires and pipes are damaged, leaking electricity or oil.

- Raw nuts are of different sizes and should be graded before opening, generally in 3-4 grades.

- The gap between the feed hopper and the shell opening blade has been adjusted before leaving the factory. The customer can run the machine directly without adjusting the blade, but if the shell opening effect is not satisfactory, the customer can also adjust it slightly.

- Customers can adjust the height of the upper knife body and the depth of the blade in this way to ensure the shelling rate.

Parameter of the automatic cashew nut shelling machine

| Model | Power(kw) | Capacity(kg) | Shelling rate | Weight(kg) | Dimension(mm) |

| TZ-BKJ-2 | 0.75 | 35-45 | 95% | 200 | 1450*500*1200 |

| TZ-BKJ-6 | 0.75 | 150 | 95% | 420 | 1450*1000*1550 |

| TZ-BKJ-10 | 1.5 | 260-340 | 95% | 560 | 1450*1700*1550 |

The maintenance of the cashew nut shelling machine

- After a period of use, the blade wears normally, and the user can disassemble and sharpen the blade or replace the blade. So as not to affect the opening rate.

- The user should regularly fill the motor lubricating oil, the bearing (with a lubrication hole), and the chain tension. We recommend filling up every half a month. Especially for electric motor gearboxes, the oil level should be kept above the oil standard, and it is best to add lubricant to the electric motor every two to three months.