Ligne de production de pain pita entièrement automatique | Machine à pain arabe commerciale

La ligne de production industrielle de pain pita est une solution entièrement automatisée et intégrée, conçue pour la production de masse de pain pita arabe moelleux et de pain plat. Cette usine de transformation complète — qui comprend une pétrisseuse, une presse à calandrer la pâte, une façonneuse et un four tunnel continu — offre une capacité de production de 100 à 500 kg/h (jusqu’à 2 000 pièces/heure). Elle est conçue pour produire une épaisseur de produit final de 1 à 2 mm et peut être configurée pour divers formats, y compris le pain rond (30 à 40 cm de diamètre) et carré (30 x 25 cm). Construite en acier inoxydable 304 de qualité alimentaire et disponible avec des systèmes de chauffage à gaz ou électriques, la ligne résout directement les principaux défis commerciaux tels que les goulets d’étranglement de la production et les coûts de main-d’œuvre élevés. La taille du produit et la production globale peuvent être personnalisées davantage, réalisant ainsi un processus de production mécanisé, économe en énergie et très efficace qui garantit une qualité constante.

Défis de Production Industrielle et Nos Solutions

Faire passer la production de pain pita à une échelle industrielle présente des défis commerciaux distincts. Notre ingénierie fournit des solutions directes et basées sur des données à ces défis, permettant une installation de production plus rentable et fiable.

Défi 1 : Goulets d’Étranglement de la Production et Coûts de Main-d’Œuvre Élevés

La production manuelle est limitée par la disponibilité de la main-d’œuvre, sa vitesse et son coût, ce qui impose un plafond à la production et à la rentabilité. Notre machine commerciale de fabrication de pain pita entièrement automatisée répond à ce problème en éliminant l’intervention manuelle aux étapes critiques. Ce niveau d’automatisation réduit la dépendance à la main-d’œuvre, minimise la formation et diminue les dépenses d’exploitation à long terme.

Défi 2 : Qualité de Produit Inconstante et Risque pour la Marque

L’inconstance est un risque majeur pour la réputation d’une marque alimentaire. Le travail manuel entraîne des variations dans l’épaisseur, le diamètre et la qualité de cuisson du produit. La ligne commerciale de machine à pain pita remplace cette improvisation par une ingénierie de précision. Ses rouleaux de pression réglables (plage de 1 à 6 mm) et un contrôle de l’épaisseur du produit final de 1 à 2 mm permettent une paramétrisation. Chaque pain pita est produit avec des spécifications identiques, protégeant ainsi la réputation de votre marque.

Défi 3 : Demandes Diverses du Marché et Production Rigide

Le marché mondial du pain pita n’est pas uniforme ; différentes régions exigent des tailles et des formes spécifiques. Une ligne de production rigide ne peut pas s’adapter. Notre système est conçu pour l’adaptabilité. Des moules de façonnage interchangeables permettent de passer d’un type de produit à l’autre, y compris le pain pita rond (30-40 cm de diamètre) et carré (30x25 cm). Cette flexibilité vous permet de répondre aux diverses demandes du marché.

Modules Clés de la Ligne de Production : Une Analyse du Processus d’Ingénierie

Chaque module de la ligne de production est conçu pour une fonction spécifique, travaillant en séquence synchronisée pour garantir l’efficacité et la qualité. L’ensemble de la ligne est construit en acier inoxydable 304 de qualité alimentaire.

Étape 1 : Mélangeur de Pâte

Le processus commence par le mélangeur de pâte. Son arbre interne imite le pétrissage manuel, un processus critique qui développe une structure de gluten robuste, résultant en un produit final avec une texture et une élasticité améliorées.

Étape 2 : Presse à Calandrer la Pâte

La machine utilise un processus de laminage multipasse. Il s’agit d’une étape d’ingénierie qui améliore l’élasticité de la pâte, créant un pain plat résilient qui gonfle correctement pendant la cuisson.

Étape 3 : Façonneuse

Ce module remplit deux fonctions. Premièrement, ses moules interchangeables découpent les feuilles de pâte dans la forme et la taille finales. Deuxièmement, un système intégré de recyclage de la pâte de rebut récupère et réintègre les chutes dans le flux de production, réduisant ainsi le gaspillage de matières premières et augmentant les marges bénéficiaires.

Étape 4 : Four Tunnel à Pain Pita

Le four tunnel continu de pain pita garantit que chaque pièce est cuite uniformément. Pour des exigences de volume plus élevées, la production peut être doublée avec des configurations personnalisées à double rangée. L’option chauffée au gaz offre une opportunité d’économie pour les producteurs à grande échelle où le gaz naturel est une source d’énergie industrielle plus économique.

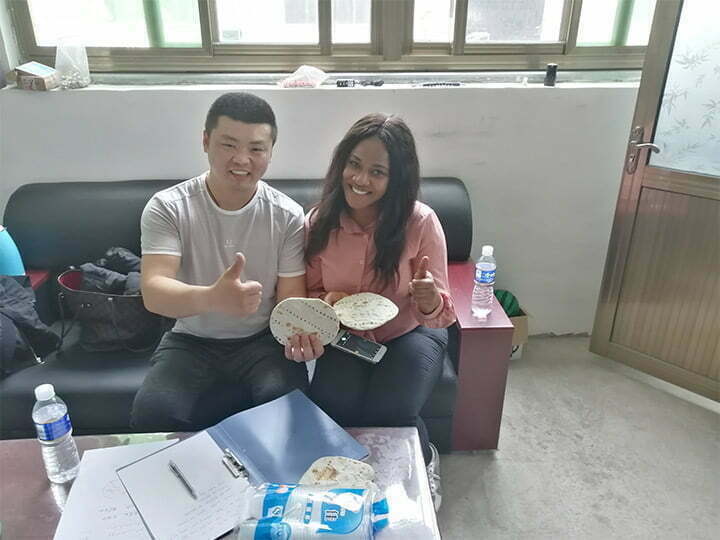

Validation Client Mondiale : Le Choix des Entreprises en Turquie et aux Émirats Arabes Unis

Nos lignes de production de pain pita sont en exploitation commerciale sur plusieurs marchés clés, avec un succès avéré auprès des transformateurs alimentaires en Turquie et aux Émirats Arabes Unis. Ces clients ont choisi notre équipement en raison de sa fiabilité, de son efficacité et de la qualité du produit final.

Fiche Technique Complète

Cette fiche technique fournit tous les détails techniques nécessaires à l’évaluation par vos équipes d’ingénierie et d’approvisionnement.

| Module | Paramètre | Valeur |

|---|---|---|

| Mélangeur de Pâte | Capacité | 50 kg/lot |

| Pouvoir | 2,2 KW | |

| Poids | 250 kg | |

| Dimensions (L×l×H) | 980 × 510 × 1010 mm | |

| Presse à Calandrer la Pâte | Largeur du Rouleau | 350 mm |

| Capacité | 350 kg/h | |

| Pouvoir | 3 KW / 4 KW | |

| Poids | 250 kg | |

| Dimensions (L×l×H) | 1330 × 615 × 1060 mm | |

| Façonneuse à Pain Pita | Capacité | 1 000 kg/h |

| Pouvoir | 2,2 KW | |

| Poids | 300 kg | |

| Dimensions (L×l×H) | 1900 × 730 × 1100 mm | |

| Plage d’Épaisseur | 1 – 6 mm | |

| Matériaux | Acier Inoxydable + Bande Transporteuse Alimentaire PVC | |

| Four Tunnel à Pain Pita | Capacité | 800 pièces/h (de base) |

| Puissance de la Bande | 1,2 KW | |

| Tension | 220 V (personnalisable) | |

| Poids | 560 kg | |

| Dimensions (L×l×H) | 2650 × 830 × 1020 mm | |

| Options de Chauffage | Électrique / Gaz |

Un Investissement Stratégique dans Votre Succès Commercial

En résumé, notre ligne de production entièrement automatique de pain pita est plus qu’un ensemble de machines ; c’est un investissement stratégique dans la scalabilité, la standardisation et la rentabilité de votre entreprise. En résolvant les défis industriels clés avec une ingénierie robuste et des performances basées sur des données, ce système fournit la base d’une croissance durable et d’un leadership sur le marché.

Passez à l’Étape Suivante

Nous comprenons que chaque besoin de production est unique. Afin de vous fournir les informations les plus pertinentes, veuillez sélectionner l’option qui correspond le mieux à vos besoins actuels :

Pour un accès immédiat à toutes les données techniques pour votre évaluation interne.

Pour une discussion détaillée sur la personnalisation, l’intégration et la manière dont cette ligne peut être adaptée à vos objectifs de production spécifiques.

Pour les décideurs prêts à recevoir une proposition de prix détaillée et personnalisée basée sur votre capacité et vos configurations requises.

Foire Aux Questions (FAQ)

-

Quelle est la fourchette de prix pour cette ligne de production complète ?

Étant donné que nos lignes sont modulaires et configurées selon les besoins spécifiques de chaque client (capacité, type de chauffage, taille du produit), il n’y a pas de prix fixe. Pour fournir un devis précis, nos ingénieurs ont besoin d’une brève consultation pour comprendre vos objectifs de production. Notre objectif est de fournir la solution la plus rentable, pas la plus chère. Contactez-nous pour obtenir un devis préliminaire pour votre entreprise.

-

Quelle est la période approximative de retour sur investissement (ROI) ?

Le ROI dépend de vos coûts de main-d’œuvre locaux, de vos coûts de matières premières et du prix du produit. Nos clients constatent généralement un retour rapide grâce à : 1) Réduction des coûts de main-d’œuvre en réduisant le travail manuel à seulement 1 à 2 opérateurs ; 2) Augmentation des revenus grâce à une production plus élevée (de base 800 pièces/h) ; et 3) Réduction des déchets grâce à notre système de recyclage des rebuts. D’après les retours des clients, la période de ROI est souvent comprise entre 12 et 24 mois.

-

La ligne peut-elle être personnalisée pour notre taille et notre épaisseur de pain pita spécifiques ?

Absolument. La personnalisation est l'une de nos forces fondamentales. Nous pouvons créer des moules de formage sur mesure pour toutes tailles et formes. L'épaisseur du rouleau est précisément réglable de 1 à 6 mm pour obtenir le produit final souhaité. Nous pouvons également tester votre farine ou recette spécifique dans notre établissement pour garantir une compatibilité parfaite.

-

Qu'en est-il de la fiabilité à long terme et des marques de composants clés ?

La fiabilité est un principe de conception principal. Toutes les pièces en contact avec les aliments sont en acier inoxydable 304. Nous utilisons des marques réputées et standardisées de l’industrie pour les composants critiques tels que les moteurs, les roulements et les systèmes électriques afin d’assurer un fonctionnement stable à long terme. La durabilité de notre équipement a été prouvée dans des environnements commerciaux en Turquie, aux Émirats Arabes Unis et dans d’autres pays.

-

Quel support après-vente et quelle garantie offrez-vous aux clients internationaux ?

Nous fournissons un système de support global complet : une garantie de 12 mois, un support technique à distance 24/7, un stock de pièces de rechange facilement disponible pour une expédition internationale rapide, et l'option d'un service d'ingénieur sur site pour des besoins d'installation ou de maintenance complexes.

-

Comment l'installation et la formation des opérateurs sont-elles gérées ?

Nous proposons deux options flexibles. L’Installation Guidée à Distance, utilisant des manuels détaillés et un support vidéo, est suffisante pour la plupart des clients. Pour un démarrage sans problème, nous recommandons l’Installation sur Site, où notre ingénieur se rend dans vos locaux pour superviser l’installation, la mise en service et fournir une formation pratique complète à votre équipe.

-

L'équipement est-il conforme aux normes de sécurité alimentaire et électriques de mon pays (par exemple, États-Unis, UE) ?

Notre équipement est construit selon les principes internationaux de BPF (Bonnes Pratiques de Fabrication). Nous pouvons configurer les systèmes électriques et les dispositifs de sécurité pour répondre à des normes régionales spécifiques, telles que le marquage CE pour l'Europe ou UL pour les États-Unis, afin de garantir que votre ligne passe les inspections de conformité locales. Veuillez nous informer des normes requises lors de votre consultation.