Vollautomatische Pita-Brot-Produktionslinie | Gewerbliche Maschine zur Herstellung von arabischem Brot

Die industrielle Pita-Brot-Produktionslinie ist eine vollautomatische, integrierte Lösung, die für die Massenproduktion von weichem arabischem Pita-Brot und Fladenbrot entwickelt wurde. Diese komplette Verarbeitungsanlage – die eine Teigknetmaschine, eine Teigplattenpresse, eine Formmaschine und einen kontinuierlichen Tunnelofen umfasst – liefert eine Produktionskapazität von 100-500 kg/h (bis zu 2.000 Stück/Stunde). Sie ist für eine Endproduktdicke von 1-2 mm ausgelegt und kann für verschiedene Formate konfiguriert werden, darunter runde (30-40 cm Durchmesser) und quadratische (30*25 cm) Brote. Die Linie ist aus lebensmittelechtem 304 Edelstahl gefertigt und mit Gas- oder Elektroheizungssystemen erhältlich. Sie löst direkt zentrale kommerzielle Herausforderungen wie Produktionsengpässe und hohe Arbeitskosten. Sowohl die Produktgröße als auch der Gesamtausstoß können weiter individuell angepasst werden, was einen mechanisierten, energiesparenden und hocheffizienten Produktionsprozess mit garantierter gleichbleibender Qualität ermöglicht.

Industrielle Produktionsherausforderungen & Unsere Lösungen

Die Skalierung der Pita-Brot-Produktion auf einen industriellen Betrieb stellt spezifische kommerzielle Herausforderungen dar. Unsere Ingenieurskunst bietet direkte, datengesteuerte Lösungen für diese Herausforderungen und ermöglicht eine rentablere und zuverlässigere Produktionsanlage.

Herausforderung 1: Produktionsengpässe & Hohe Arbeitskosten

Die manuelle Produktion ist durch Arbeitsverfügbarkeit, Geschwindigkeit und Kosten begrenzt, was eine Obergrenze für Ausstoß und Rentabilität darstellt. Unsere vollautomatische gewerbliche Pita-Brot-Maschine begegnet dem, indem sie manuelle Eingriffe in kritischen Phasen eliminiert. Dieses Automatisierungsniveau reduziert die Abhängigkeit von Arbeitskräften, minimiert den Schulungsaufwand und senkt die langfristigen Betriebskosten.

Herausforderung 2: Inkonsistente Produktqualität & Markenrisiko

Inkonsistenz ist ein primäres Risiko für den Ruf einer Lebensmittelmarke. Manuelle Arbeit führt zu Schwankungen bei Produktdicke, Durchmesser und Backqualität. Die gewerbliche Pita-Brot-Maschinenlinie ersetzt dieses Rätselraten durch präzise Ingenieurskunst. Ihre einstellbaren Andruckwalzen (Bereich 1-6 mm) und die Endprodukt-Dickenkontrolle von 1-2 mm ermöglichen die Parametrisierung. Jedes Pita-Brot wird mit identischen Spezifikationen hergestellt, was den Ruf Ihrer Marke schützt.

Herausforderung 3: Vielfältige Marktanforderungen & Unflexible Produktion

Der globale Markt für Pita-Brot ist nicht einheitlich; verschiedene Regionen verlangen spezifische Größen und Formen. Eine starre Produktionslinie kann sich nicht anpassen. Unser System ist auf Anpassungsfähigkeit ausgelegt. Austauschbare Formwerkzeuge ermöglichen den Wechsel zwischen Produkttypen, einschließlich runden (30-40 cm Durchmesser) und quadratischen (30×25 cm) Pita-Broten. Diese Flexibilität ermöglicht es Ihnen, vielfältige Marktanforderungen zu erfüllen.

Kernmodule der Produktionslinie: Eine Aufschlüsselung des Ingenieurprozesses

Jedes Modul der Produktionslinie ist für eine bestimmte Funktion konzipiert und arbeitet in einer synchronisierten Sequenz, um Effizienz und Qualität zu gewährleisten. Die gesamte Linie ist aus lebensmittelechtem 304 Edelstahl gefertigt.

Schritt 1: Teigknetmaschine

Der Prozess beginnt mit der Teigknetmaschine. Ihre interne Welle ahmt das manuelle Kneten nach, ein kritischer Prozess, der eine robuste Glutenstruktur entwickelt, was zu einem Endprodukt mit verbesserter Textur und Elastizität führt.

Schritt 2: Teigplattenpresse

Die Maschine verwendet einen Mehrfachwalzprozess. Dies ist ein ingenieurtechnischer Schritt, der die Elastizität des Teigs verbessert und ein widerstandsfähiges Fladenbrot erzeugt, das während des Backens richtig aufgeht.

Schritt 3: Formmaschine

Dieses Modul erfüllt zwei Funktionen. Erstens schneiden seine austauschbaren Formen die Teigplatten in die endgültige Form und Größe. Zweitens sammelt ein integriertes Abfallteig-Recycling-System Teigschnittreste und führt sie dem Produktionsfluss wieder zu, wodurch Rohstoffabfälle reduziert und die Gewinnmargen erhöht werden.

Schritt 4: Tunnel-Pita-Brot-Ofen

Der kontinuierliche Tunnel-Pita-Brot-Ofen sorgt dafür, dass jedes Stück gleichmäßig gebacken wird. Für höhere Volumensanforderungen kann die Leistung durch kundenspezifische Doppelreihenkonfigurationen verdoppelt werden. Die gasbeheizte Option bietet eine kostensparende Möglichkeit für Großproduzenten, bei denen Erdgas eine wirtschaftlichere industrielle Energiequelle ist.

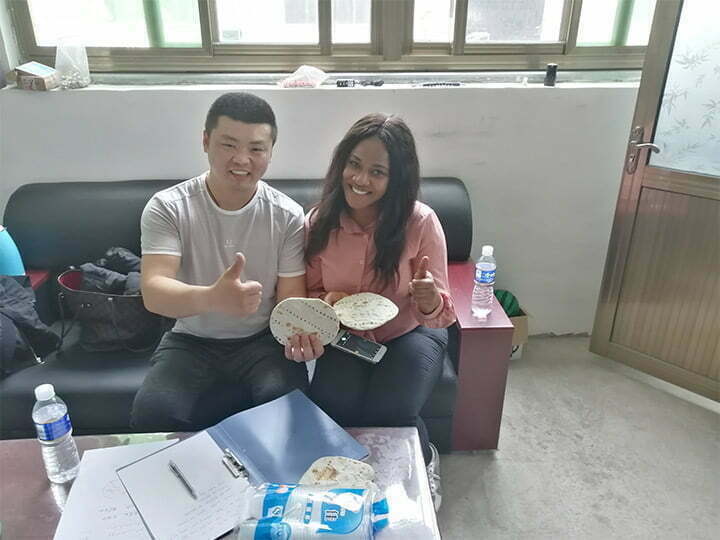

Globale Kundenvalidierung: Die Wahl von Unternehmen in der Türkei und den Vereinigten Arabischen Emiraten

Unsere Pita-Brot-Produktionslinien sind in mehreren Schlüsselmärkten im kommerziellen Einsatz und haben sich bei Lebensmittelproduzenten in der Türkei und den Vereinigten Arabischen Emiraten bewährt. Diese Kunden wählten unsere Ausrüstung aufgrund ihrer Zuverlässigkeit, Effizienz und der Qualität des Endprodukts.

Vollständiges technisches Datenblatt

Dieses Datenblatt liefert alle notwendigen technischen Details zur Auswertung durch Ihre Ingenieur- und Beschaffungsteams.

| Modul | Parameter | Wert |

|---|---|---|

| Teigknetmaschine | Kapazität | 50 kg/Charge |

| Leistung | 2,2 KW | |

| Gewicht | 250 kg | |

| Abmessungen (L×B×H) | 980 × 510 × 1010 mm | |

| Teigplattenpresse | Walzenbreite | 350 mm |

| Kapazität | 350 kg/h | |

| Leistung | 3 KW / 4 KW | |

| Gewicht | 250 kg | |

| Abmessungen (L×B×H) | 1330 × 615 × 1060 mm | |

| Pita-Brot-Formmaschine | Kapazität | 1.000 kg/h |

| Leistung | 2,2 KW | |

| Gewicht | 300 kg | |

| Abmessungen (L×B×H) | 1900 × 730 × 1100 mm | |

| Dickenbereich | 1 – 6 mm | |

| Materialien | Edelstahl + PVC-Lebensmittel-Förderband | |

| Pita-Brot-Tunnelofen | Kapazität | 800 Stück/h (Basis) |

| Bandleistung | 1,2 KW | |

| Stromspannung | 220 V (anpassbar) | |

| Gewicht | 560 kg | |

| Abmessungen (L×B×H) | 2650 × 830 × 1020 mm | |

| Heizoptionen | Elektro / Gas |

Eine strategische Investition in Ihren kommerziellen Erfolg

Zusammenfassend lässt sich sagen, dass unsere vollautomatische Pita-Brot-Produktionslinie mehr als nur eine Maschinenserie ist; sie ist eine strategische Investition in die Skalierbarkeit, Standardisierung und Rentabilität Ihres Unternehmens. Durch die Lösung zentraler industrieller Herausforderungen mit robuster Ingenieurskunst und datengesteuerter Leistung bietet dieses System die Grundlage für nachhaltiges Wachstum und Marktführerschaft.

Machen Sie den nächsten Schritt

Wir verstehen, dass jede Produktionsanforderung einzigartig ist. Um Ihnen die relevantesten Informationen zukommen zu lassen, wählen Sie bitte die Option, die Ihren aktuellen Bedürfnissen am besten entspricht:

Für sofortigen Zugriff auf alle technischen Daten zur internen Bewertung.

Für eine detaillierte Diskussion über Anpassung, Integration und wie diese Linie auf Ihre spezifischen Produktionsziele zugeschnitten werden kann.

Für Entscheidungsträger, die bereit sind, einen detaillierten, personalisierten Preisvorschlag basierend auf Ihrer erforderlichen Kapazität und Konfigurationen zu erhalten.

Häufig gestellte Fragen (FAQ)

-

Wie liegt der Preisrahmen für diese komplette Produktionslinie?

Da unsere Linien modular und auf die spezifischen Bedürfnisse jedes Kunden zugeschnitten sind (Kapazität, Heizart, Produktgröße), gibt es keinen Festpreis. Um ein genaues Angebot zu erstellen, benötigen unsere Ingenieure eine kurze Beratung, um Ihre Produktionsziele zu verstehen. Unser Ziel ist es, die kostengünstigste Lösung anzubieten, nicht die teuerste. Kontaktieren Sie uns, um ein vorläufiges Angebot für Ihr Unternehmen zu erhalten.

-

Wie lange ist der ungefähre Zeitraum für die Amortisation (ROI)?

Der ROI hängt von Ihren lokalen Arbeitskosten, Rohstoffkosten und Produktpreisen ab. Unsere Kunden erzielen in der Regel eine schnelle Rendite durch: 1) Einsparungen bei den Arbeitskosten durch Reduzierung der manuellen Arbeit auf nur 1-2 Bediener; 2) Umsatzsteigerung durch höheren Ausstoß (Basis 800 Stück/h); und 3) Reduzierung von Abfall durch unser Abfallrecyclingsystem. Basierend auf Kundenfeedback liegt die ROI-Periode oft zwischen 12 und 24 Monaten.

-

Kann die Linie für unsere spezifische Pita-Brot-Größe und -Dicke angepasst werden?

Absolut. Anpassung ist eine unserer Kernstärken. Wir können maßgeschneiderte Formmuster für jede Größe und Form erstellen. Die Rollerdicke ist präzise von 1-6 mm einstellbar, um Ihr gewünschtes Endprodukt zu erreichen. Wir können auch Ihr spezifisches Mehl oder Rezept in unserem Werk testen, um perfekte Kompatibilität sicherzustellen.

-

Wie sieht es mit der langfristigen Zuverlässigkeit und den Marken der Hauptkomponenten aus?

Zuverlässigkeit ist ein primäres Konstruktionsprinzip. Alle Teile mit Lebensmittelkontakt sind aus 304 Edelstahl gefertigt. Wir verwenden renommierte Industriestandardmarken für kritische Komponenten wie Motoren, Lager und elektrische Systeme, um einen stabilen, langfristigen Betrieb zu gewährleisten. Die Langlebigkeit unserer Ausrüstung wurde in kommerziellen Umgebungen in der Türkei, den Vereinigten Arabischen Emiraten und anderen Ländern bewiesen.

-

Welche After-Sales-Unterstützung und Garantie bieten Sie internationalen Kunden an?

Wir bieten ein umfassendes globales Unterstützungssystem: eine 12-monatige Garantie, 24/7 technischen Support aus der Ferne, einen jederzeit verfügbaren Lagerbestand an Ersatzteilen für schnellen internationalen Versand und die Möglichkeit eines Vor-Ort-Service durch Ingenieure für komplexe Installations- oder Wartungsbedürfnisse.

-

Wie werden Installation und Schulung der Bediener gehandhabt?

Wir bieten zwei flexible Optionen. Ferngesteuerte Installation, unter Verwendung detaillierter Handbücher und Video-Unterstützung, ist für die meisten Kunden ausreichend. Für einen reibungslosen Start empfehlen wir eine Vor-Ort-Installation, bei der unser Ingenieur zu Ihrer Anlage reist, um die Installation und Inbetriebnahme zu überwachen und umfassende praktische Schulungen für Ihr Team durchzuführen.

-

Entspricht die Ausrüstung den Lebensmittel- und elektrischen Sicherheitsstandards in meinem Land (z. B. USA, EU)?

Unsere Geräte werden gemäß internationalen GMP (Good Manufacturing Practice) Richtlinien hergestellt. Wir können die elektrischen Systeme und Sicherheitsmerkmale so konfigurieren, dass sie spezifischen regionalen Standards entsprechen, wie z.B. CE für Europa oder UL für die Vereinigten Staaten, um sicherzustellen, dass Ihre Linie die lokalen Compliance-Prüfungen besteht. Bitte informieren Sie uns über Ihre erforderlichen Standards während Ihrer Beratung.